Row template blanking type automatic particle counting device

A particle counting device and blanking technology, which is applied in the field of row die blanking type automatic particle counting device, can solve the problems of difficult quality assurance, easy vibration and dust, and work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

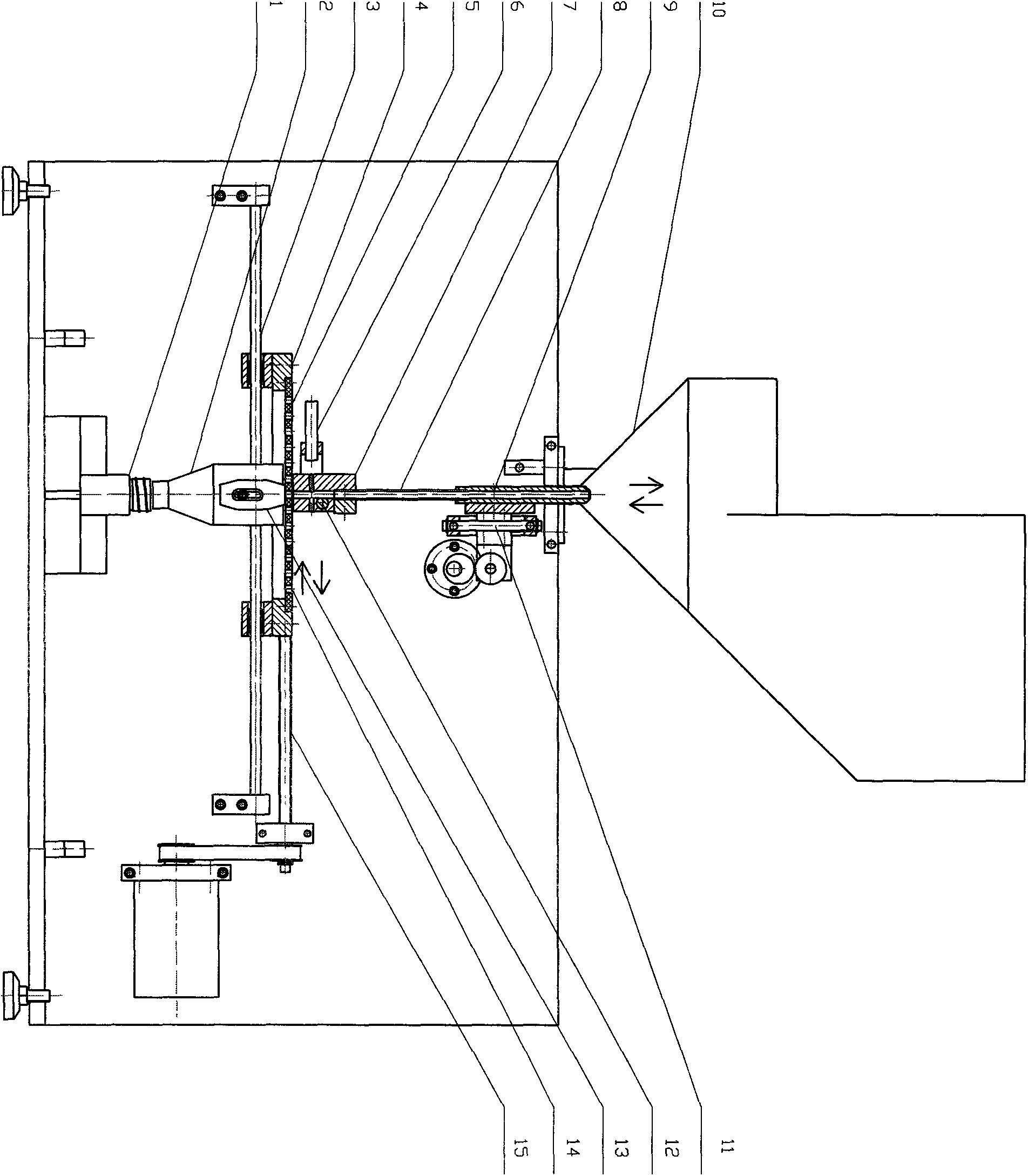

[0013] As shown in the figure, this embodiment is a row mold blanking type automatic counting device, which is characterized in that the device includes a distribution hopper 2, a guide rail 3, a row mold seat 4, a row template 5, a photoelectric switch 6, a pipe seat 7, Telescopic pipe 8, mold pipe 9, loading hopper 10, guide rail 2 11, blanking control valve 12, distributor 13, die hole 14, screw mandrel 15, pipe seat 7 is provided with photoelectric switch 6 and control valve 12, The formwork 5 is provided with corresponding mold holes 14 according to the shape and size of the granular body, and the pipe holes of the traveling mold pipeline 9 are corresponding to the shape and size of the granular body.

[0014] The loading hopper 10 of the device is filled with material particles, and the traveling mold pipeline 9 is guided by the guide rail 2 11 to reciprocate up and down. The pellets are controlled on and off by the blanking control valve 12 set on the pipe seat 7, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com