Waterproof oil-proof antistatic non-woven fabric and producing method thereof

A waterproof and oil-proof, production method technology, applied in textiles, papermaking, fiber processing and other directions, can solve the problems of easy formation of precipitation, loss of waterproof and oil-proof, reduced water pressure resistance effect of non-woven fabrics, etc., and achieves high water pressure resistance retention rate. Lightweight, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

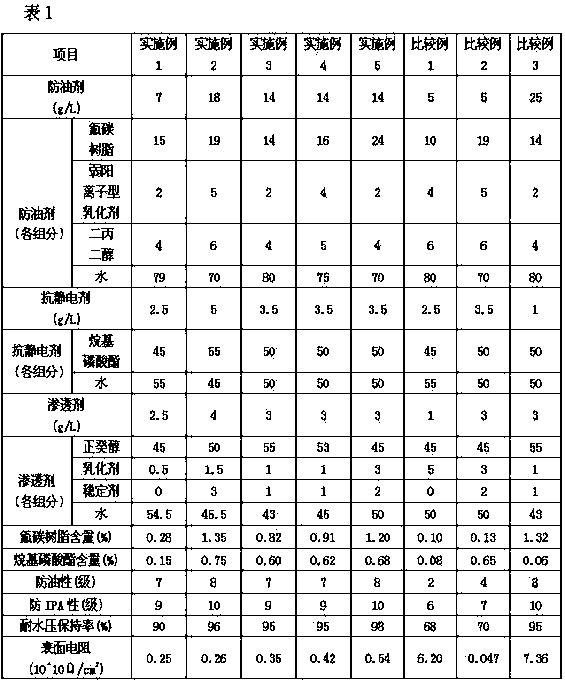

Examples

Embodiment 1

[0031] Take 15 parts of fluorocarbon resin, 2 parts of weak cationic emulsifier, 4 parts of dipropylene glycol, and 79 parts of water, stir and mix evenly to prepare an oil repellent for use;

[0032] Take 55 parts of deionized water and 45 parts of alkyl phosphate, stir and mix evenly to make antistatic agent for subsequent use;

[0033] Take 45 parts of n-decyl alcohol, 0.5 part of emulsifier, 0 part of stabilizer, and 54.5 parts of water, stir and mix evenly to make penetrant for later use;

[0034] Mix the prepared anti-oil agent, antistatic agent, penetrating agent and water, and then stir with a stirring time of 4 minutes and a stirring speed of 400 rpm, and the ratio of the three to water is oil antistatic agent: antistatic Agent: Penetrant=7g / L: 2.5g / L: 2.5g / L;

[0035] Pass the non-woven gray fabric through the above mixed solution, pass the roll at a speed of 35m / min, the dipping time is 2s, and the roll pressure is 2Kgf / cm 2 Rolling under the temperature of 140°C ...

Embodiment 2

[0037] Take 19 parts of fluorocarbon resin, 5 parts of weak cationic emulsifier, 6 parts of dipropylene glycol, and 70 parts of water, stir and mix evenly to prepare an oil repellent for use;

[0038] Get 45 parts of deionized water and 55 parts of alkyl phosphate, stir and mix evenly to make antistatic agent for subsequent use;

[0039] Take 50 parts of n-decyl alcohol, 1.5 parts of emulsifier, 3 parts of stabilizer, and 45.5 parts of water, stir and mix evenly to make penetrant for later use;

[0040] Mix the prepared anti-oil agent, antistatic agent, penetrating agent and water, and then stir with a stirring time of 4 minutes and a stirring speed of 400 rpm, and the ratio of the three to water is oil antistatic agent: antistatic Agent: Penetrant = 18g / L: 5g / L: 4g / L;

[0041] Pass the non-woven gray cloth through the above mixed solution, pass the roll at a speed of 45m / min, the dipping time is 0.5s, and the roll pressure is 4Kgf / cm 2 Rolling under the temperature of 150°C...

Embodiment 3

[0043] Take 14 parts of fluorocarbon resin, 2 parts of weak cationic emulsifier, 4 parts of dipropylene glycol, and 80 parts of water, stir and mix evenly to make oil repellant for later use;

[0044] Take 50 parts of deionized water and 50 parts of alkyl phosphate, stir and mix evenly to make an antistatic agent for subsequent use;

[0045] Take 55 parts of n-decyl alcohol, 1 part of emulsifier, 1 part of stabilizer, and 43 parts of water, stir and mix evenly to make penetrant for later use;

[0046] Mix the prepared anti-oil agent, antistatic agent, penetrating agent and water, and then stir with a stirring time of 4 minutes and a stirring speed of 400 rpm, and the ratio of the three to water is oil antistatic agent: antistatic Agent: Penetrant = 14g / L: 3.5g / L: 3g / L;

[0047] Pass the non-woven gray fabric through the above mixed solution, pass the roll at a speed of 40m / min, the dipping time is 1s, and the roll pressure is 4Kgf / cm 2 Rolling under the temperature of 140°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com