Volute tongue structure of fan for range hood

A technology for range hoods and fans, which is applied to components of pumping devices for elastic fluids, machines/engines, mechanical equipment, etc., can solve the problems of generating vortices, the overall efficiency of fans cannot be improved, and noise reduction, etc. The effect of overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

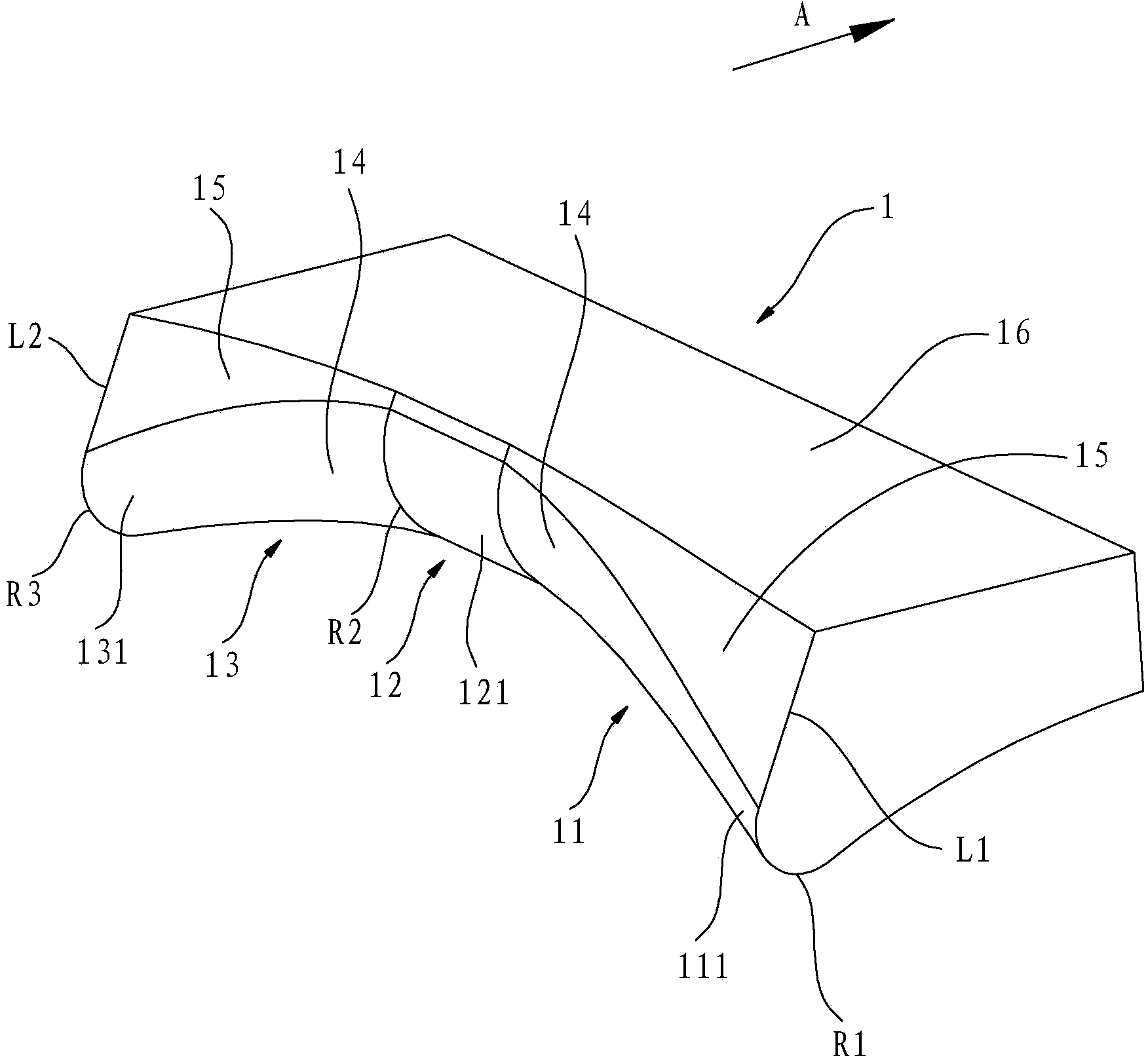

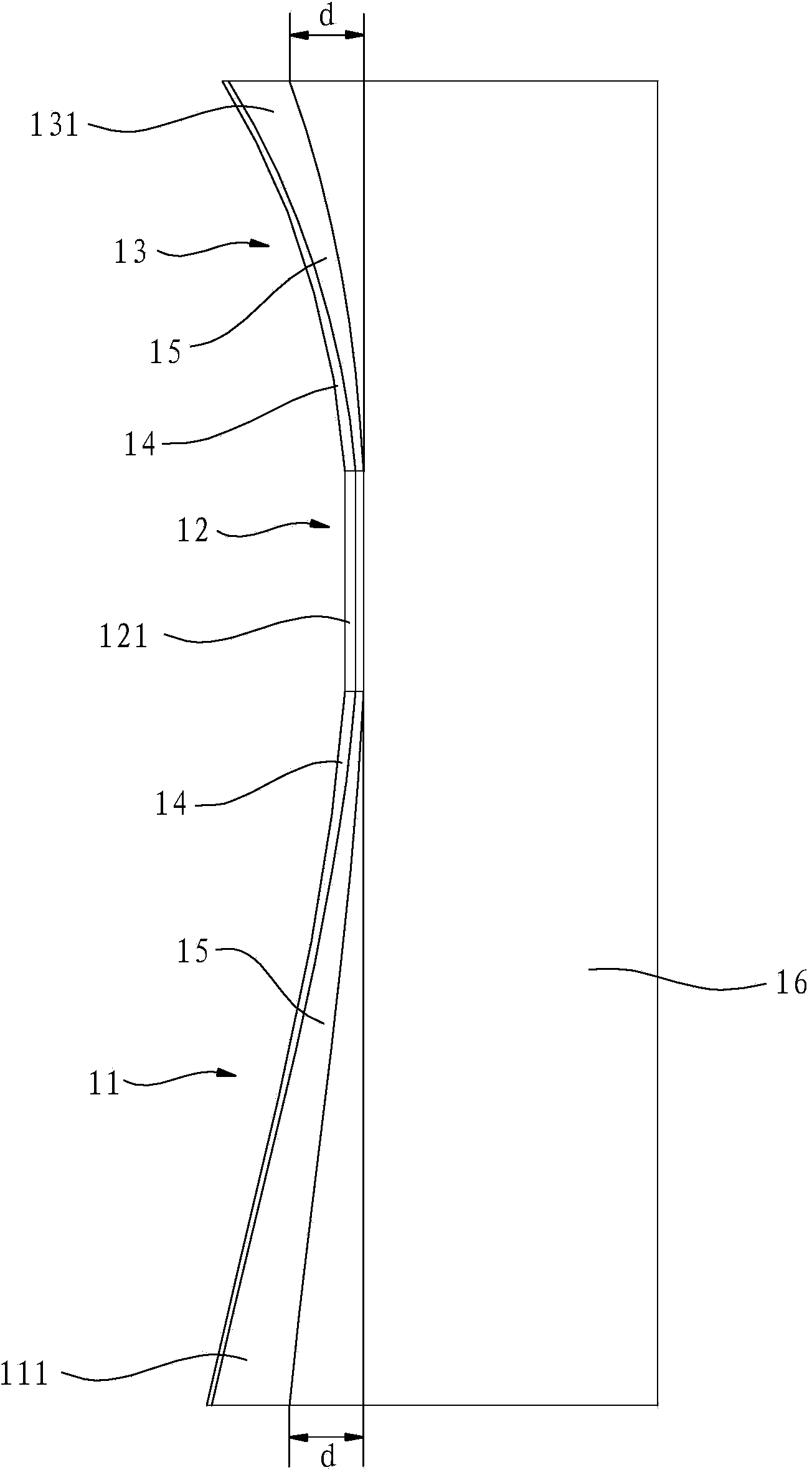

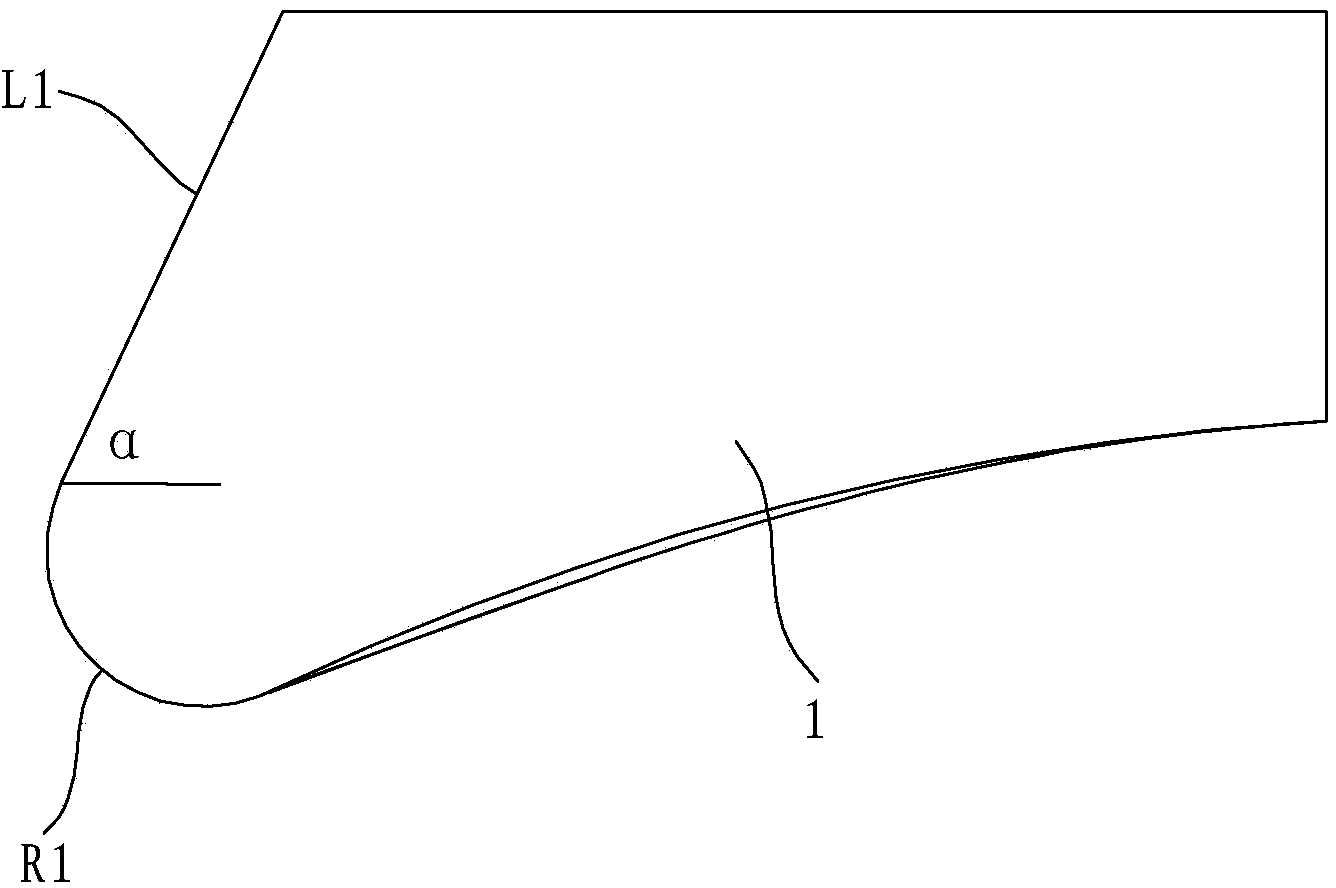

[0022] Such as Figure 1 to Figure 3 As shown, the volute tongue in this embodiment has a front plate 11, a middle plate 12 and a rear plate 13, and the front plate 11, the middle plate 12 and the rear plate 13 are integrally formed parts. Refer to the comparative document with the title of the invention "Range Hood and Its Volute Case and Volute Tongue" (Application No. 201210210890.X (Application Publication No. 103512064 A)), the volute tongue of the comparative document is on the side facing the air outlet of the fan has an inner concave surface to figure 1 The direction shown by the straight arrow A is right. Assuming that the volute tongue in this embodiment has the inner concave surface shown in the above-mentioned reference document, the front plate 11 extends to the lower left corner to form a front deep tongue 111, and the rear plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com