Screw

A screw and screw head technology, which is applied in the field of positioning parts, can solve the problems of insufficient tightness of the screwdriver and the screw groove, the reduction of the transmission torque value, and the damage of the screw starting groove, so as to save labor processing costs and eliminate the radial force, reduce the effect of rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention and its beneficial effects will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

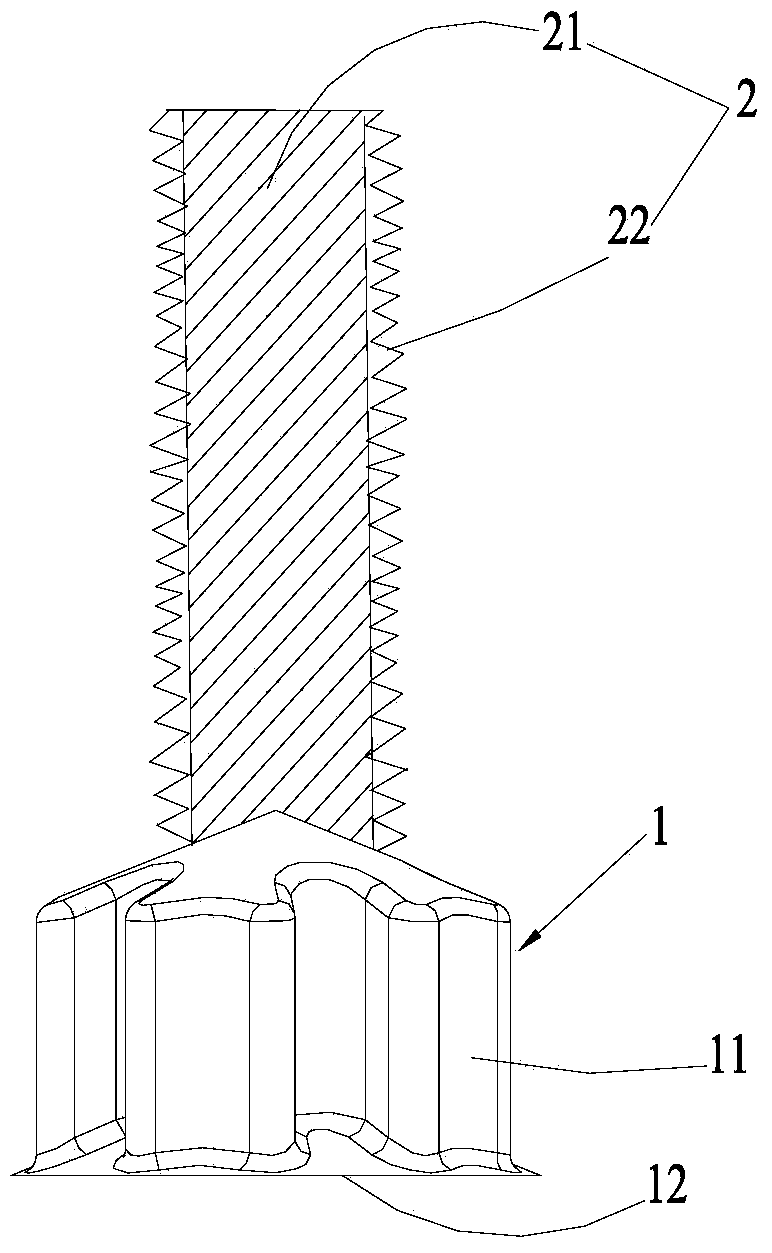

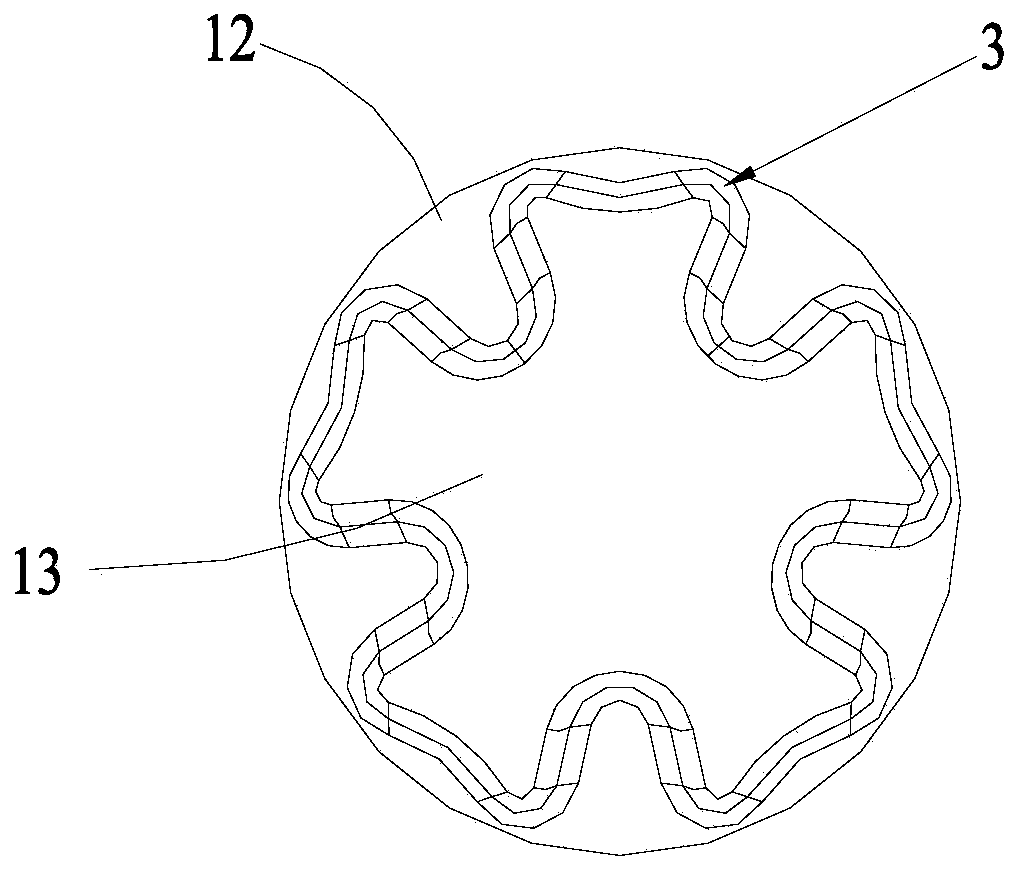

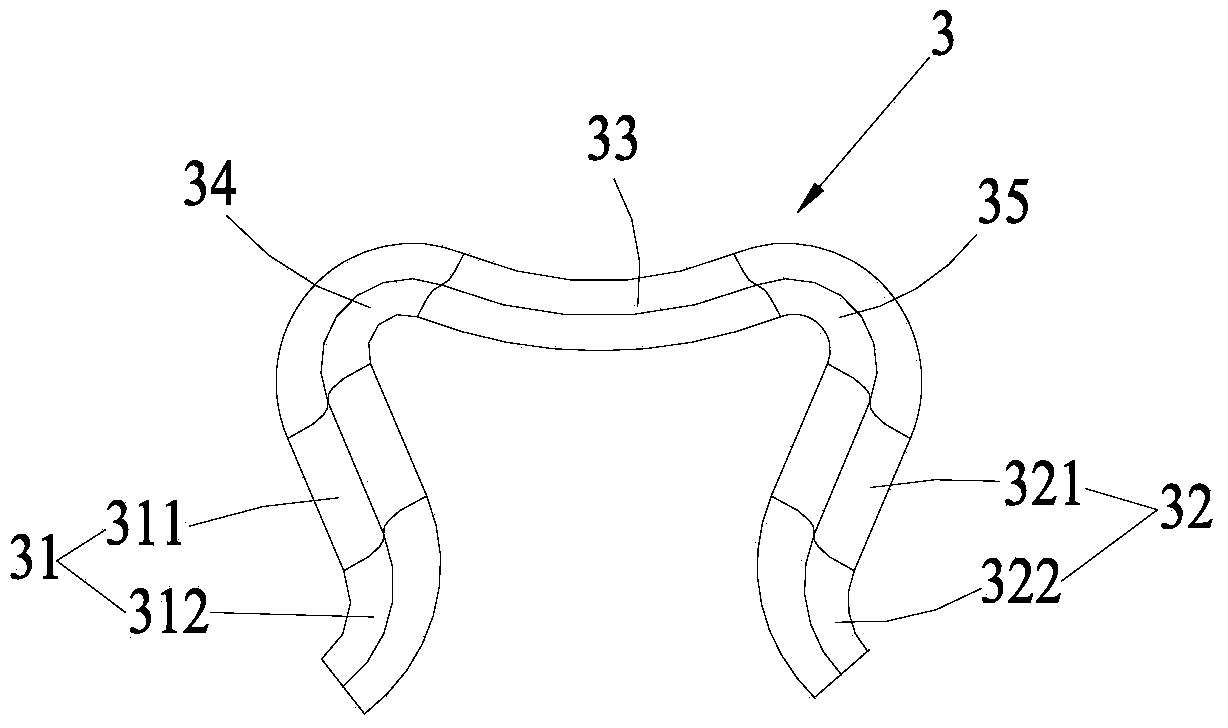

[0022] Such as Figures 1 to 3 As shown, the screw provided by the present invention includes a screw head 1 and a screw segment 2 extending downward from the screw head 1. The screw segment 2 includes a rod body 21 extending downward from the screw head 1 and several outer parts formed on the rod body 21. The tooth portion 22, the screw head 1 includes a screw head main body 11 and a starting plane 12 arranged at one end of the screw head main body 11, a screw groove 13 is arranged in the screw head 11, and the cross section of the screw groove 13 has five sequentially connected The closed structure that " several " shape protruding teeth 3 forms, the shape of this closed structure is similar to quincunx (the present invention calls it five-leaf shape). To be exact, the shape of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com