Automatic production line for knuckle bearing assembling

An automatic production line and joint bearing technology, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of low positioning accuracy, low degree of automation, and low assembly efficiency, and achieve high positioning accuracy, positioning efficiency, and automation High efficiency and high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

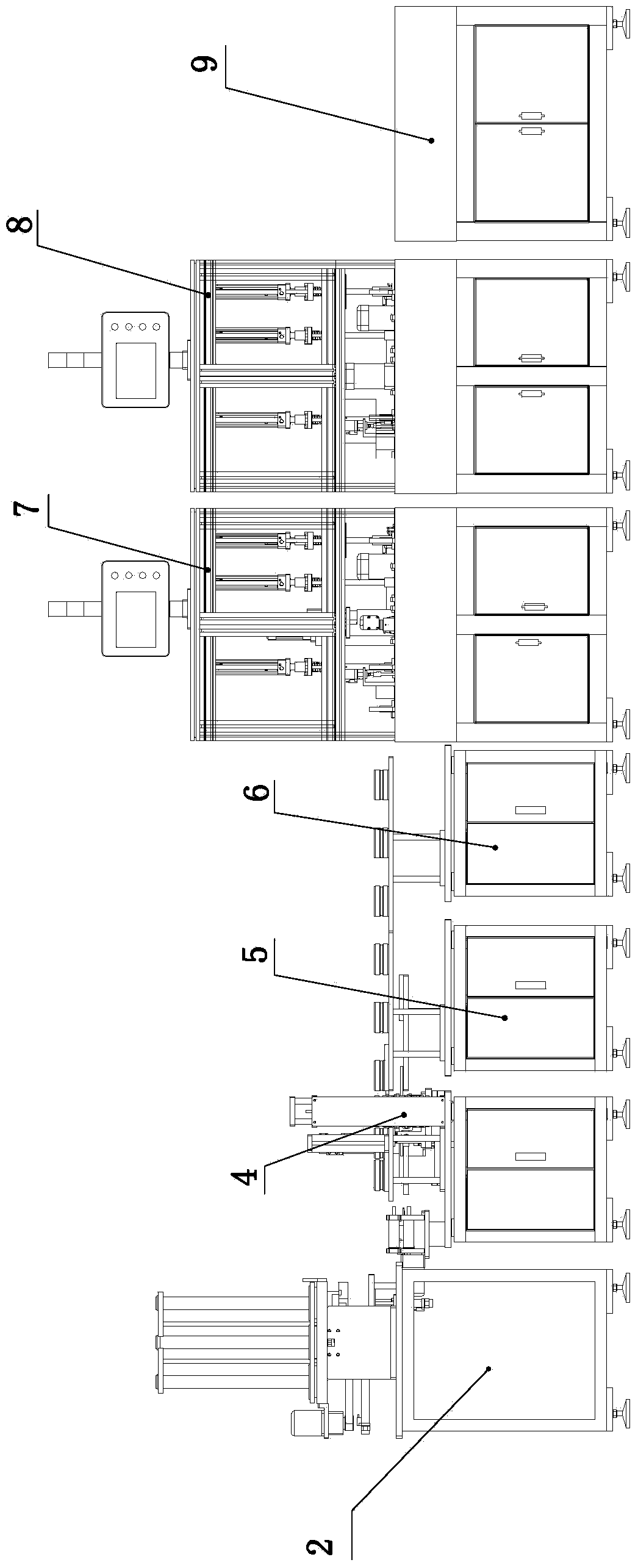

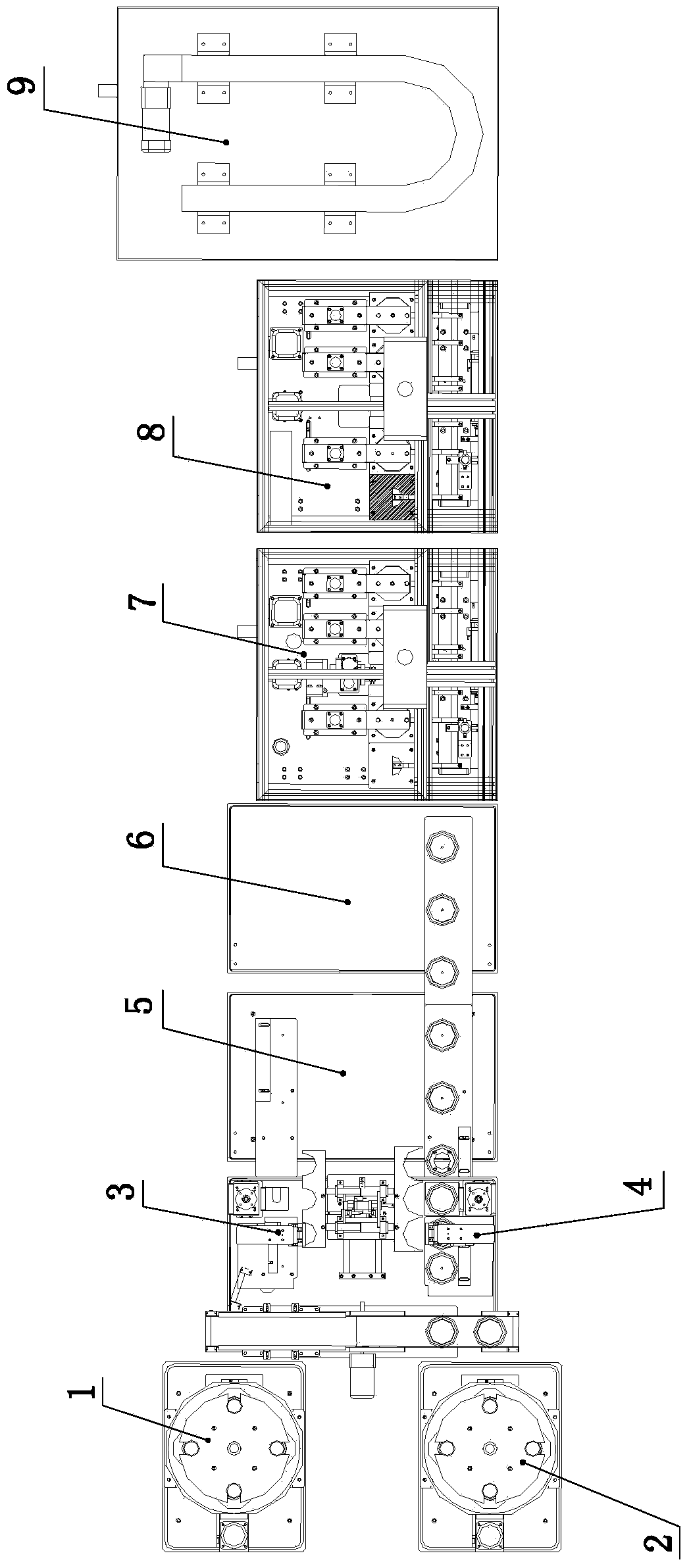

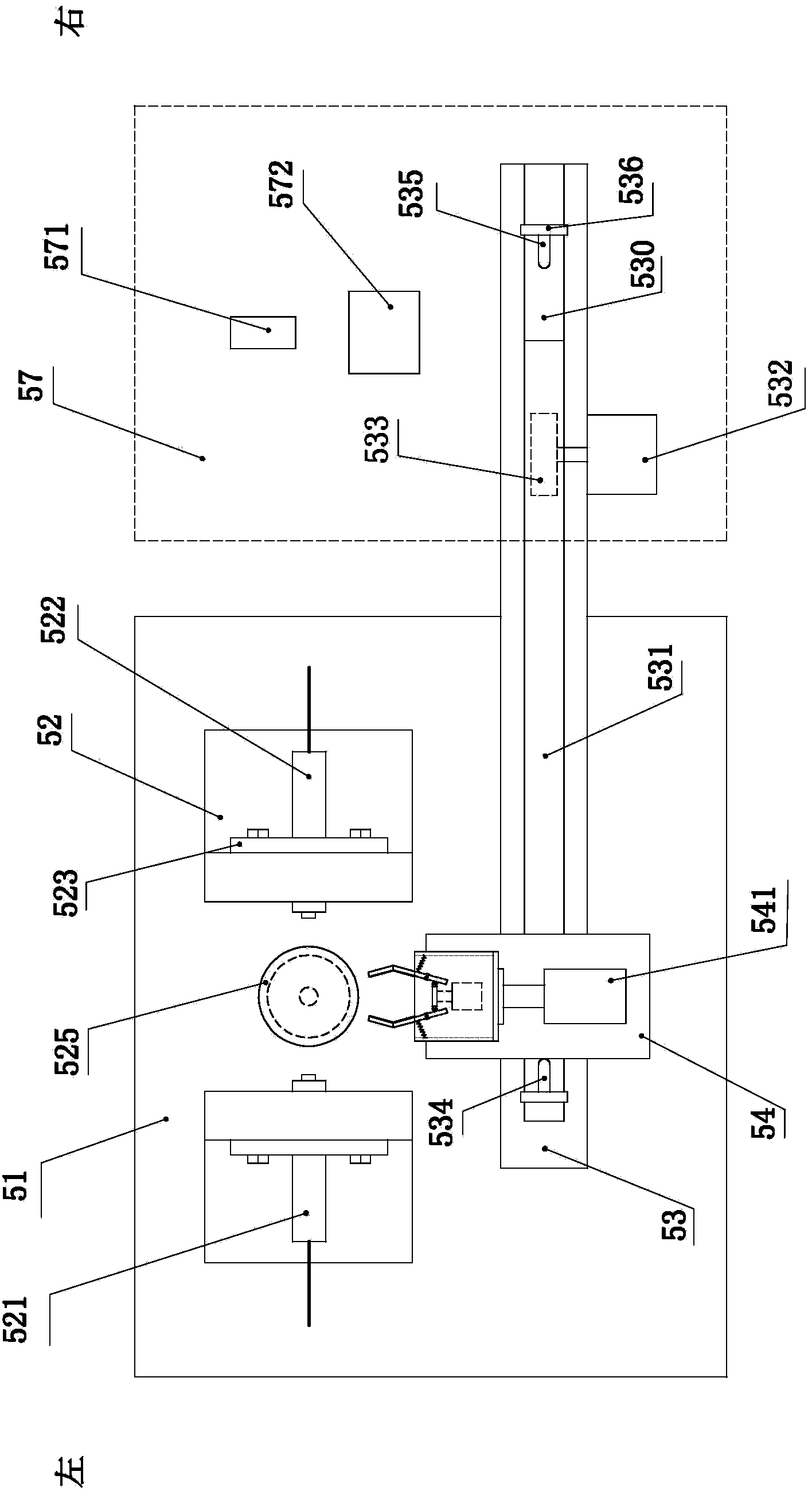

[0027] Such as Figure 1 to Figure 2 As shown, the present invention includes an inner ring feeding and storing machine 1, an outer ring feeding and storing machine 2, an inner ring measuring machine 3, an outer ring measuring machine 4, a positioning sewing device 5, and a gap detection device arranged in sequence. device, laser marking machine 6, finished product cleaning machine 7, finished product oiling machine 8 and finished product sorting and packaging machine 9, and conveyor belts are arranged between each equipment set before and after.

[0028] Such as Figure 10 As shown, the inner ring feeding stocker 1 is used to store the inner ring 10 of the joint bearing, and the inner ring feeding stocker 1 is provided with four vertically placed columns 11, and the four columns are respectively located on four sides of a square. corner position. The spherical plain bearing inner ring is placed between four uprights. A jacking cylinder 12 is provided at the center of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com