Chain guide mechanism

一种引导机构、链条的技术,应用在皮带/链条/齿轮、机械设备、传动装置等方向,能够解决链条啮合音、油压保持功能受损、张紧器T的构成部件磨损等问题,达到平滑链条行进、抑制异响产生、维持链条张力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

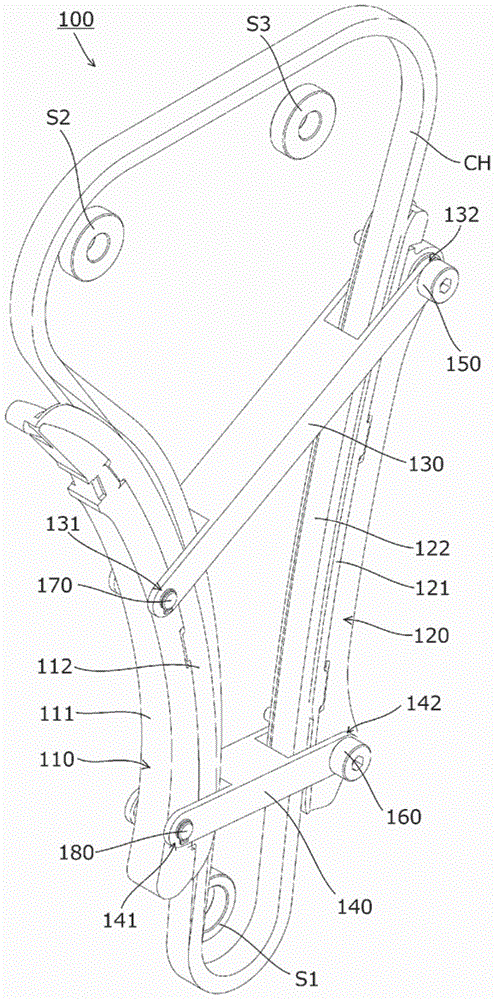

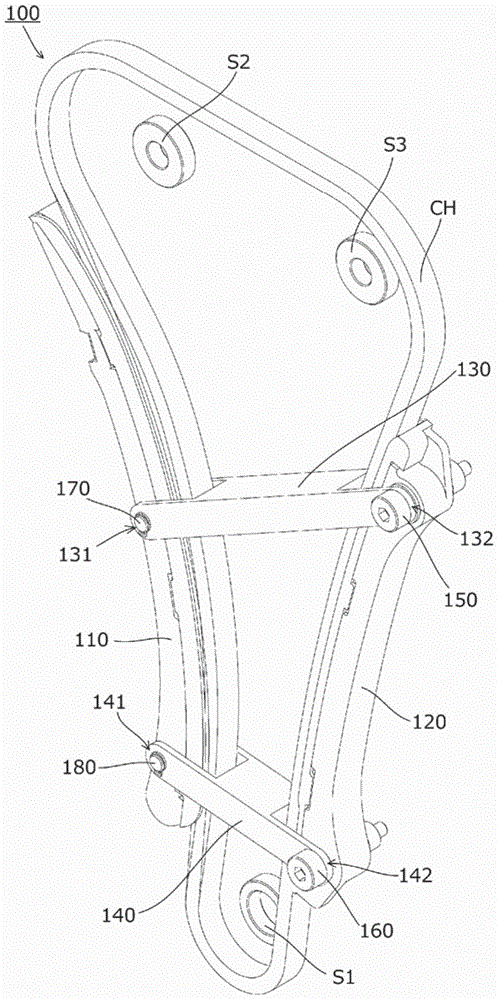

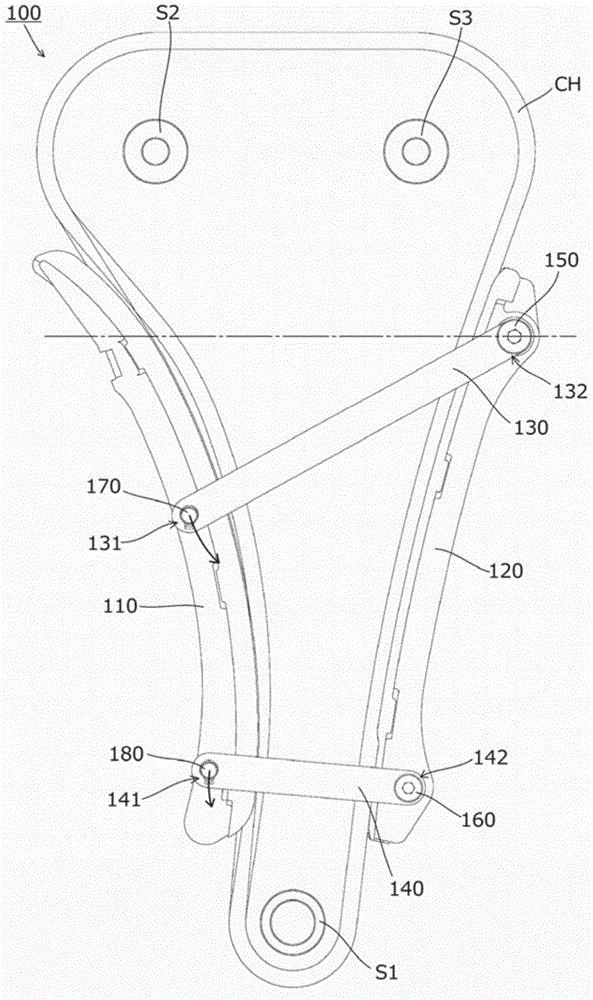

[0034]The present invention is a chain guide mechanism for guiding a chain. As long as it conforms to the following description, its specific structure can be any structure, that is, the chain guide mechanism has: a slack side guide, which is arranged on the slack side of the chain travel route; The guide is arranged on the tension side of the chain travel path; and the connecting member is rotatable around a predetermined rotation axis, the above-mentioned rotation shaft is provided in a fixed state on the installation object of the chain guide mechanism, and the connecting member has a rotatable installed on the slack-side pivot portion of the slack-side guide in such a way that the slack-side pivot portion is arranged on the opposite side of the prescribed rotation axis across the chain guided by the slack-side guide, and is arranged lower than the prescribed rotation axis. The position of the slack side guide is biased towards the side of the chain guided by the slack side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com