Sealing structure for valve body of long telescopic soot blower

A technology of sealing structure and soot blower, which is applied in the direction of shaft seal, valve details, valve device, etc., can solve problems such as delay in production, poor sealing performance of valve body, and influence on the use effect of soot blower, so as to ensure production and good quality Compression, to ensure the effect of stable progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

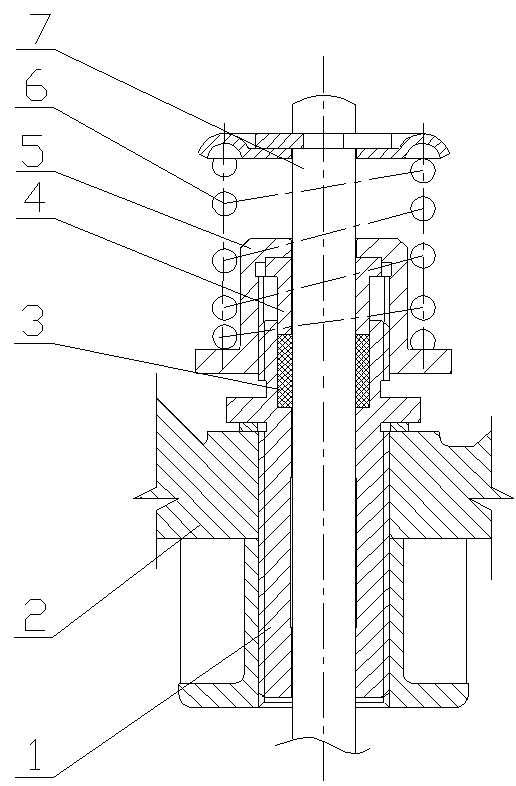

[0019] see figure 1 , the present invention relates to a long telescopic soot blower valve body sealing structure, which includes a valve body 2, a guide rod 7 and a guide sleeve 1, the valve body 2 is arranged outside the middle of the guide sleeve 1, and the guide rod 7 A packing 3 is provided between the guide sleeve 1 and the upper end of the packing 3 is provided with a packing gland 4. A stepped gland 5 is provided outside the upper end of the guide sleeve 1. The inner flange of the gland 5 is in contact with the packing pressure. The cover 4 is offset, and the gland 5 is sleeved with a spring 6 , and the lower end of the spring 6 is offset against the outer flange of the gland 5 .

[0020] Working principle: Under the action of the spring 6, the gland 5 drives the packing gland 4 to compress the packing 3, so that the packing 3 has a good degree of compression and ensures that the valve body 2 is sealed without leakage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com