Dynamic load simulation test method of airplane wheel bearing

A simulation test, dynamic load technology, applied in the direction of mechanical bearing testing, etc., can solve problems such as triggering failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

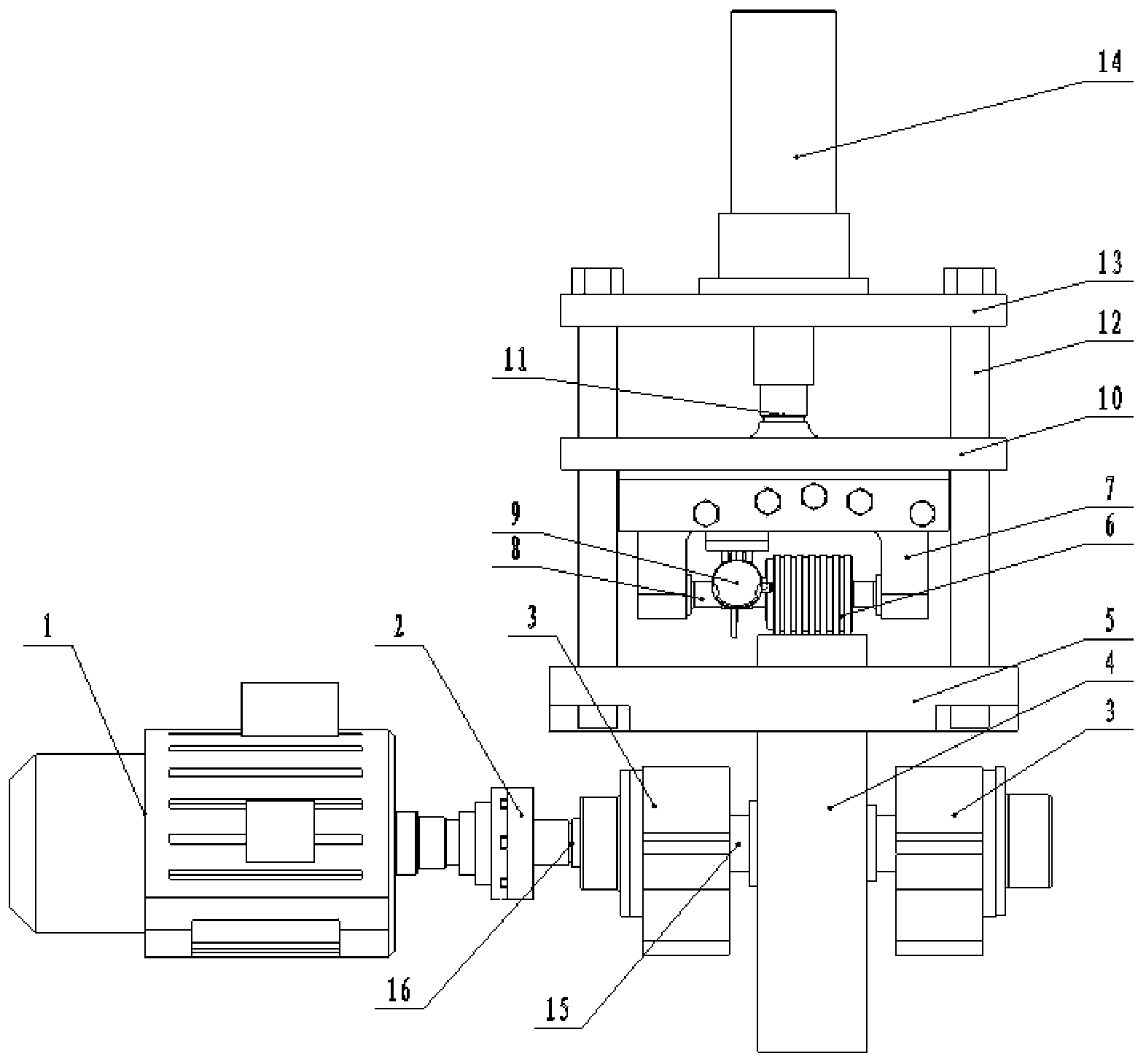

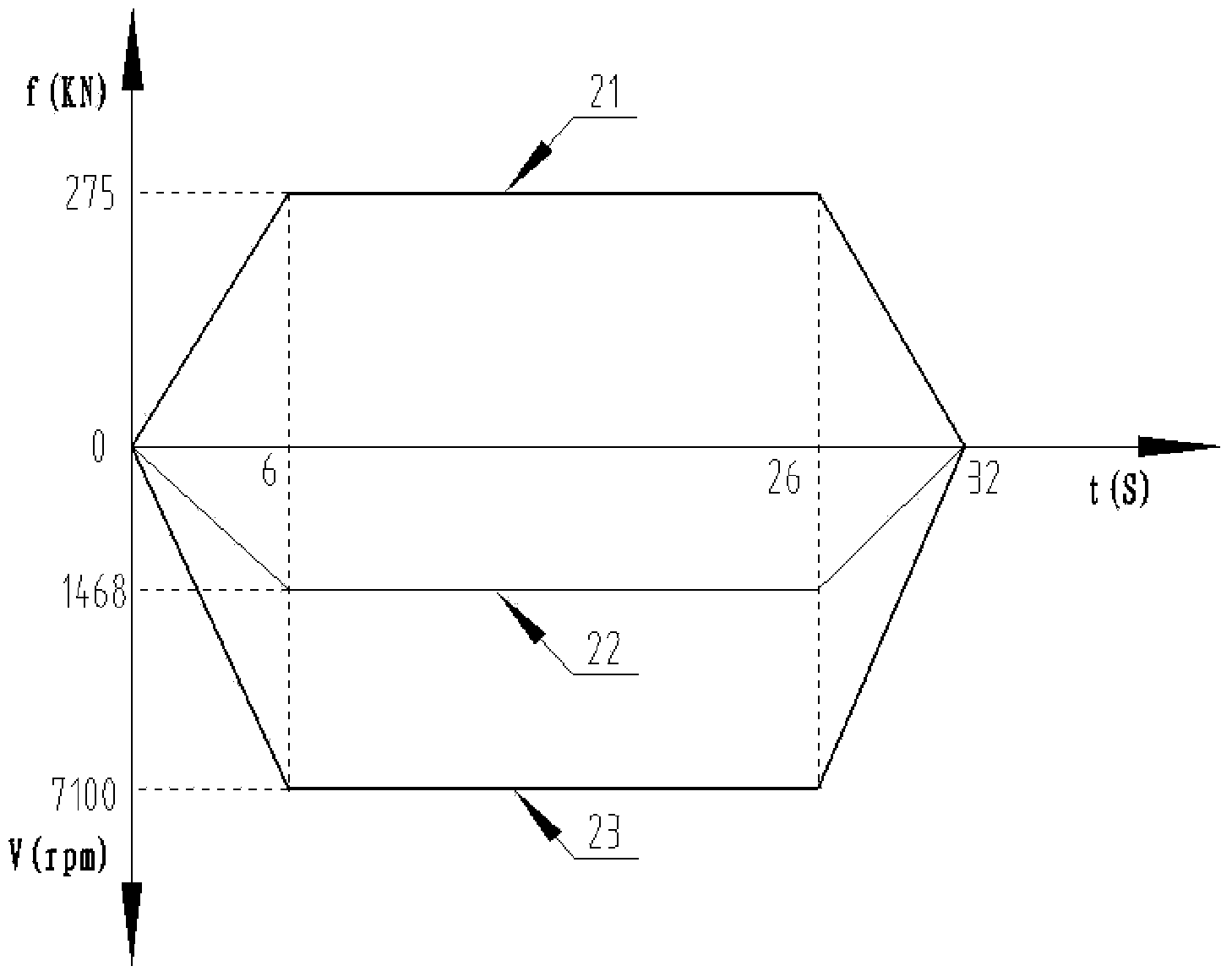

[0092] This embodiment is a dynamic load test of a certain type of aircraft wheel bearing, and the testing machine used is an aircraft wheel bearing load impact testing machine. The content of the dynamic load test includes whether the test bearing has cracks and deformation under rated load and speed, whether there is fatigue spalling or spalling depth, area size, and the temperature change curve of the inner ring of the test bearing under the action of load and rotating speed, Changes in clearance before and after the test.

[0093] The aircraft wheel bearing load impact testing machine includes a loading system and a driving system.

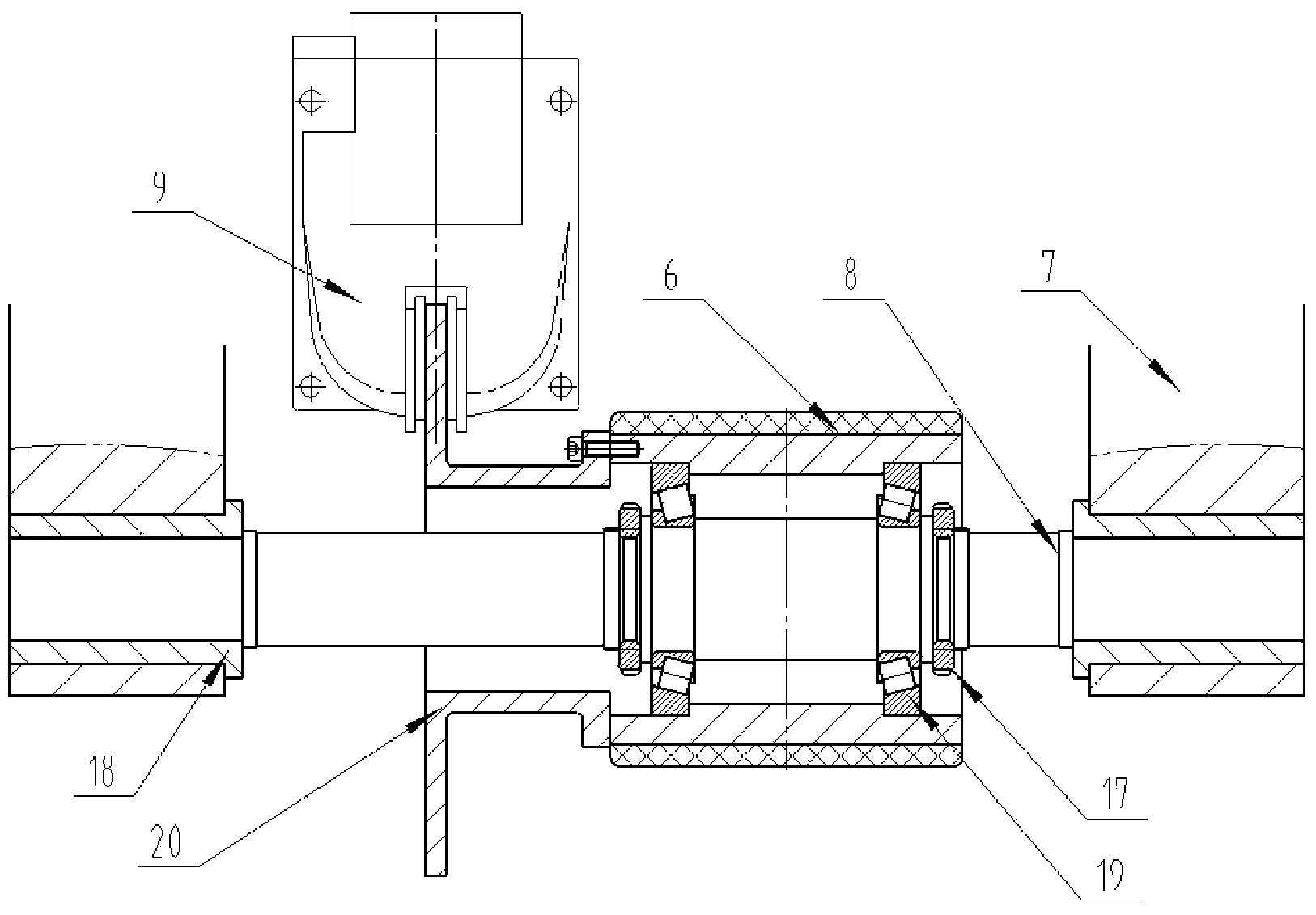

[0094] The loading system is a vertical hydraulic loading method, which is disclosed in the invention of 2014102708950. The loading system includes a base plate 5, a rubber wheel 6, a U-shaped loading head 7, a loading shaft 8, a brake 9, a movable plate 10, a load sensor 11, a column 12, a fixed plate 13, a hydraulic cylinder 14, a coupling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com