A hole checking device

A technology of inspection devices and camera devices, applied in measuring devices, instruments, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

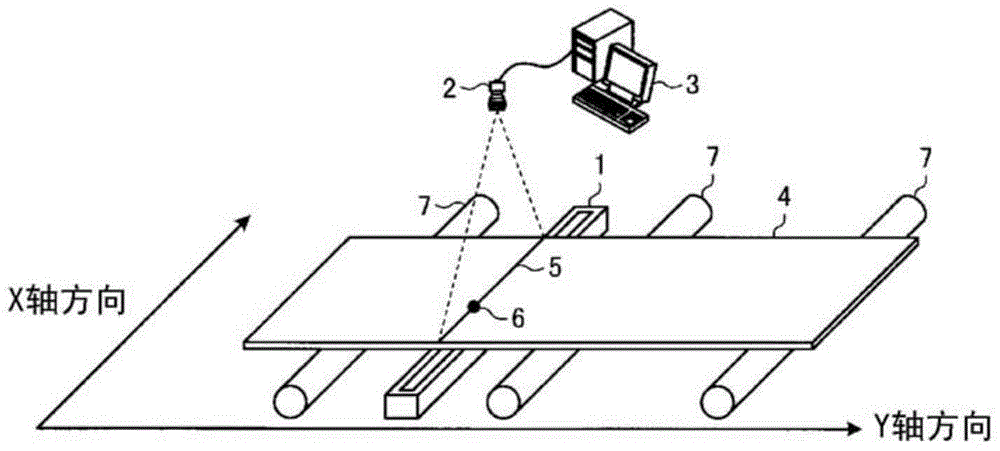

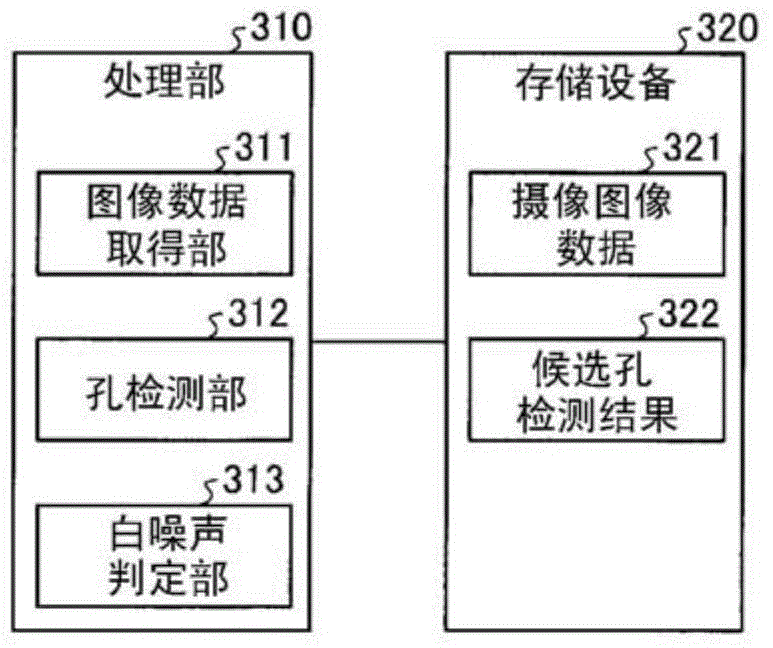

[0037] Next, a hole inspection device according to an embodiment will be described with reference to the drawings.

[0038] The hole inspection device of this embodiment removes white noise caused by cosmic ray particles generated on the output signal (video signal) of a CCD camera or a CMOS camera (hereinafter referred to as a camera) through image processing, thereby preventing erroneous detection of holes . figure 1 The overall structure including the hole inspection device of this embodiment and the steel plate to be inspected is shown. In addition, the inspection object is not limited to the steel plate, and any plate-shaped object can be used as the inspection object of the hole inspection device of this embodiment.

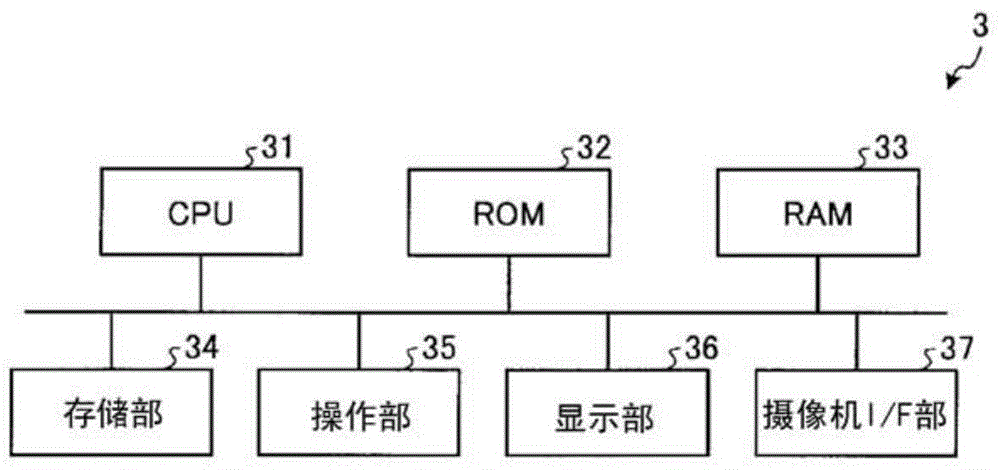

[0039] The hole inspection device includes a lighting device 1 (hereinafter referred to as lighting 1 ), such as an LED or a fluorescent lamp, a camera 2 , and a PC 3 for performing image processing. At the inspection site, such as figure 1 As shown, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com