Testing method for elastic modulus of concrete material in reinforced concrete members

A material elastic modulus, reinforced concrete technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as differences in static elastic modulus, inaccurate building structure safety, and the impact of steel bar test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] In this embodiment, the size of the reinforced concrete member is 0.2m×0.2m×1m, the stirrup is D10, the spacing is 200mm, and the longitudinal reinforcement is 4×D20.

[0096] 1. Wave speed detection steps:

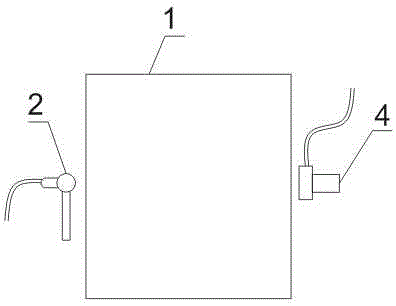

[0097] The double-sided penetration method is used for the detection of reinforced concrete members, as follows: image 3 shown. The thickness of the reinforced concrete member 1 is known, and its thickness is H=1m, and there are spaces on both sides where testing instruments can be placed. An impact hammer 2 is arranged on one side of the reinforced concrete member 1, and a sensor 4 is arranged on the other side of the reinforced concrete member 1, and the impact hammer 2 and the sensor 4 are arranged oppositely. The impact hammer 2 excites the side of the reinforced concrete member 1 to generate an impact elastic wave, which propagates to the other side and is received by the sensor 4 . get as Image 6 The waveform curve of the shock elastic wave propagating...

Embodiment 2

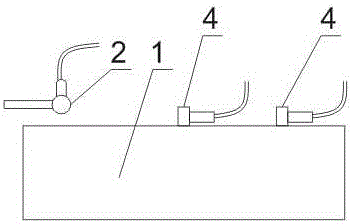

[0120] test using figure 2 The modulus of elasticity of reinforced concrete members for the one-sided propagation method shown The calculation formula is: , while the modulus of elasticity of the concrete material in the reinforced concrete member The calculation method is exactly the same as in Example 1.

Embodiment 3

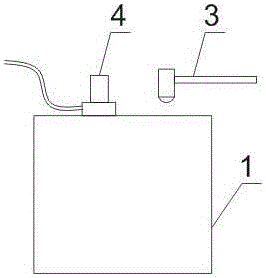

[0122] test using figure 1 The one-sided reflection method shown carries out the detection of the modulus of elasticity of the concrete material in the reinforced concrete member.

[0123] In this embodiment, the reinforced concrete member is a one-way slab of 3m×3m×0.1m, and the longitudinal reinforcement is a single row of D20 with a spacing of 0.2m.

[0124] 1. Wave speed detection steps:

[0125] The single-sided reflection method is used to detect the reinforced concrete members, specifically as figure 1 shown. Thickness of reinforced concrete member 1 It is known that it is 0.1m. The hammer 3 is used to excite the upper surface of the reinforced concrete member 1 to generate a shock elastic wave, which propagates to the lower surface of the reinforced concrete member 1 and is reflected back to the upper surface of the reinforced concrete member 1, and is located on the reinforced concrete member 1 The sensor 4 (generally an acceleration sensor) can be used to rece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com