Fuel cell electrode catalyst and manufacturing method thereof, supporting electrode of fuel cell electrode catalyst, and fuel cell

A technology for electrode catalysts and fuel cells, applied in fuel cells, battery electrodes, chemical instruments and methods, etc., can solve the problems of reduced catalyst activity and reduced usage of PtCo alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

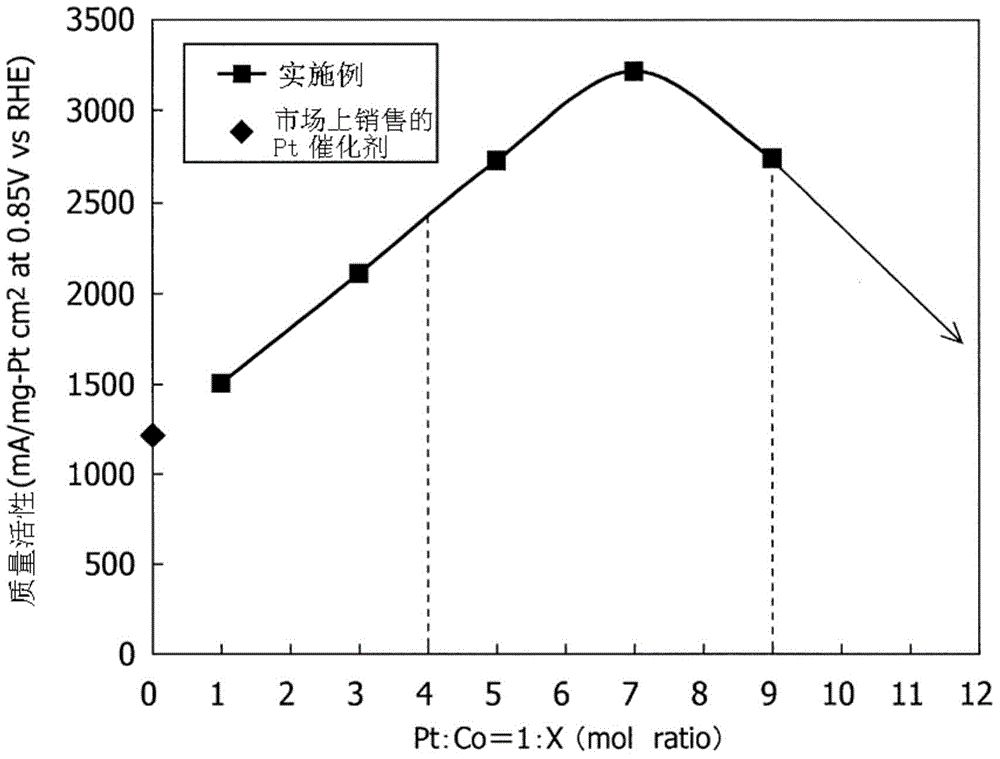

[0069] The method for producing an electrode catalyst for a fuel cell of the present invention is carried out, and the mass activity of the obtained catalyst is determined.

[0070] In the case where the noble metal is platinum (Pt) and the base metal is cobalt (Co), by adjusting the feeding amount of the platinum precursor and the cobalt precursor, the molar ratio "Pt:Co=1:X, Prepare PtCo / C alloy catalyst in the range of X=1~9”.

[0071] Specifically, the total amount of the loading of Pt+Co relative to carbon (C) was fixed at 30 wt%, and the feeding amount of each precursor (platinum precursor and cobalt precursor) was changed according to the molar ratio, while Preparation of PtCo / C alloy catalyst.

[0072] Preparation of PtCo / C Alloy Catalyst

[0073] The procedure of an example in which a PtCo / C alloy catalyst is prepared in a molar ratio (Pt:Co=1:7) is shown below.

[0074] Platinum hexahydroxide nitric acid solution (manufactured by Tanaka Kizoku Co., Ltd.) with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com