Single-phase brushless motor

A single-phase brushless motor, adjacent winding technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of small positioning starting angle, vibration and noise, low winding production efficiency, etc., to avoid The effect of sudden change of magnetic resistance, reduction of positioning torque, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions and other beneficial effects of the present invention will be apparent through the detailed description of specific embodiments of the present invention below in conjunction with the accompanying drawings. The drawings are provided for reference and illustration only, and are not intended to limit the present invention. The dimensions shown in the drawings are only for the convenience of clear description, and do not limit the proportional relationship.

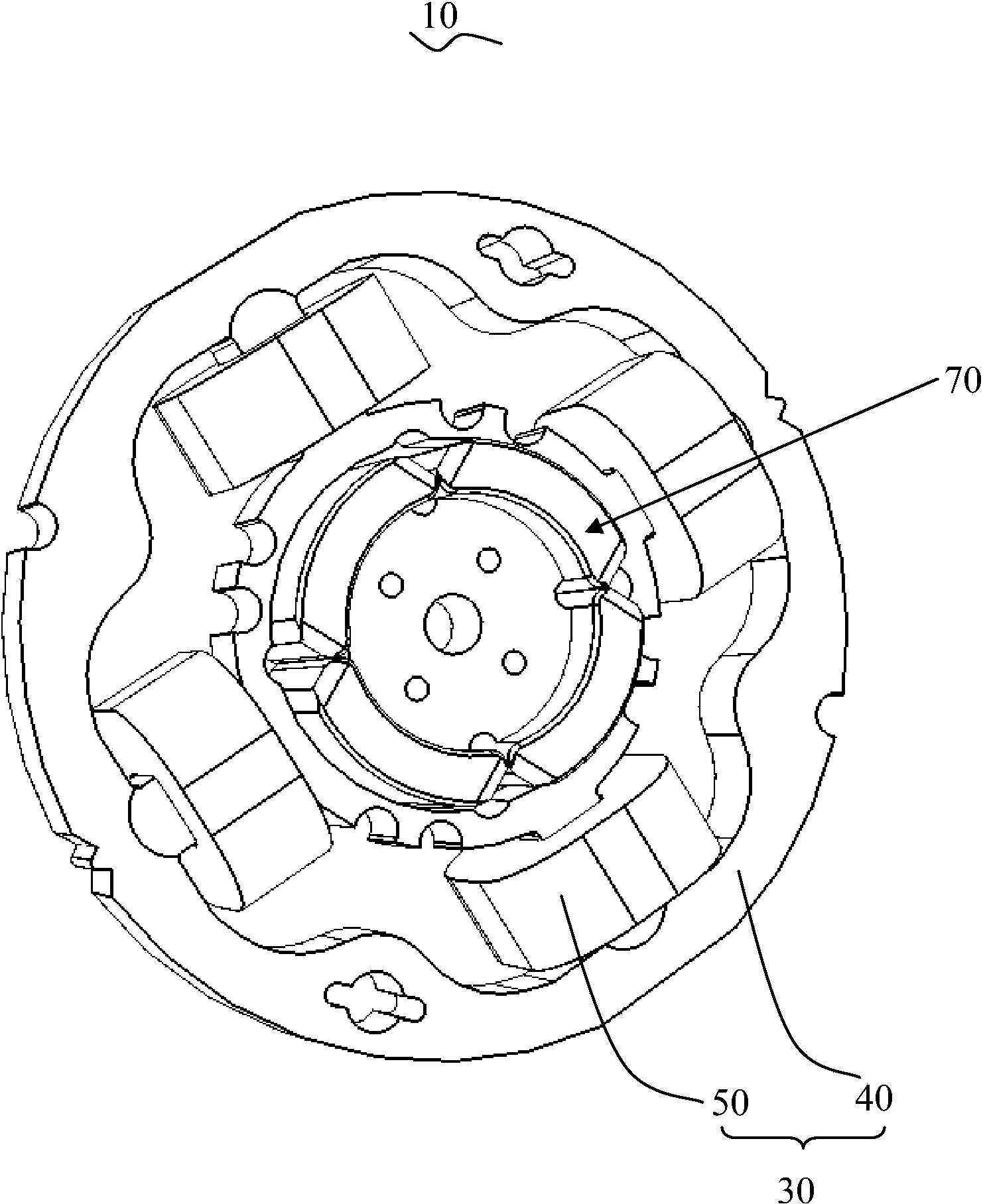

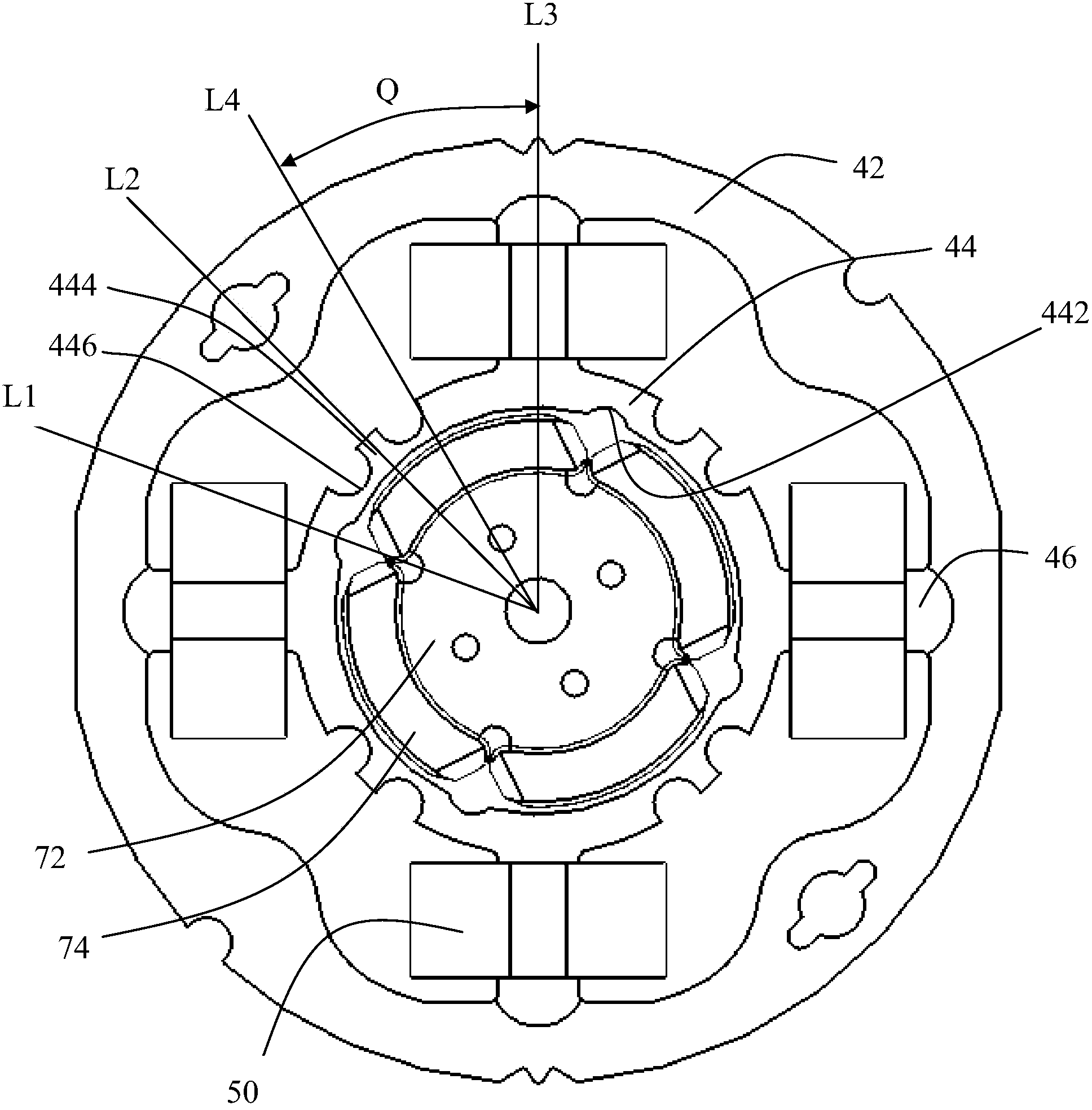

[0024] see Figure 1 to Figure 3 , a single-phase brushless motor 10 according to a preferred embodiment of the present invention includes a stator 30 and a rotor 70 rotating relative to the stator 30 .

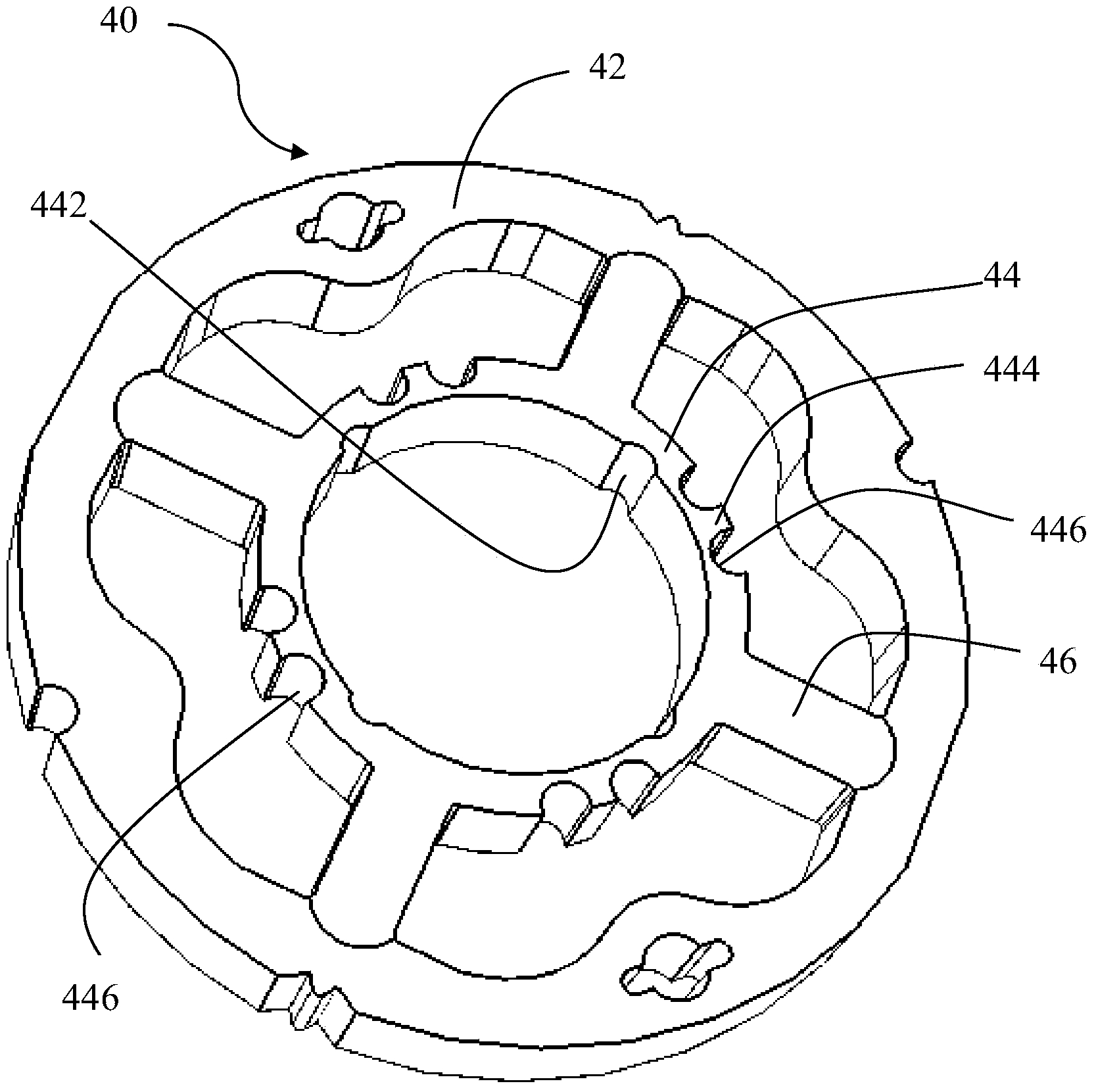

[0025] The stator 30 includes a magnetic core 40 and a winding 50 wound on the magnetic core 40 . The stator core 40 is made of magnetically permeable materials such as magnetically permeable chips (silicon steel sheets commonly used in the industry) laminated along the axial direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com