Electronic ballast of high voltage sodium lamp

A technology for electronic ballasts and high-pressure sodium lamps, applied in electric light sources, electrical components, lighting devices, etc., can solve problems such as extinguishing, lamp arc jitter, lamp damage, etc., to improve service life, improve luminous efficiency, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

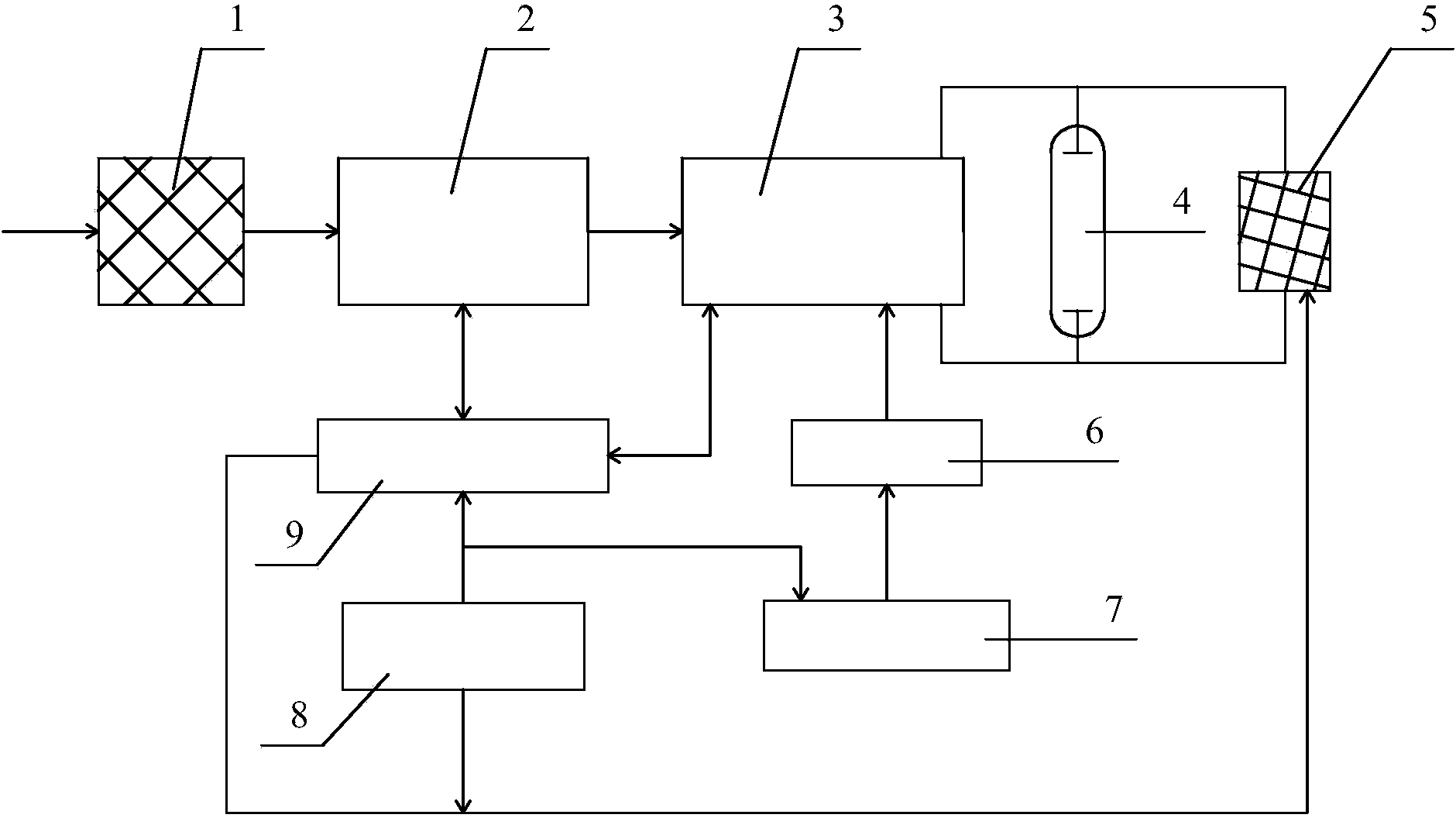

[0017] Such as figure 1 An electronic ballast for a high-pressure sodium lamp is shown, including a filter, a PFC rectifier, an inverter circuit, a high-pressure sodium lamp, an auxiliary power supply, a control circuit and a starter, the output end of the filter is connected to the PFC rectifier, and the output end of the PFC rectifier is connected to the inverter circuit The two ends of the inverter circuit are connected to the high-pressure sodium lamp, the starter is connected to the two ends of the high-pressure sodium lamp, the control circuit is respectively connected to the PFC rectifier and the inverter circuit, the auxiliary circuit is connected to the control circuit, and the inverter circuit is a high-frequency inverter circuit. The frequency is 31-37KHz, the inverter circuit is also connected with a drive circuit, and the drive circuit is connected with a frequency modulation control circuit.

[0018] The frequency of the high-frequency inverter circuit changes ±3...

Embodiment 2

[0024] Such as figure 1 An electronic ballast for a high-pressure sodium lamp is shown, including a filter, a PFC rectifier, an inverter circuit, a high-pressure sodium lamp, an auxiliary power supply, a control circuit and a starter, the output end of the filter is connected to the PFC rectifier, and the output end of the PFC rectifier is connected to the inverter circuit The two ends of the inverter circuit are connected to the high-pressure sodium lamp, the starter is connected to the two ends of the high-pressure sodium lamp, the control circuit is respectively connected to the PFC rectifier and the inverter circuit, the auxiliary circuit is connected to the control circuit, and the inverter circuit is a high-frequency inverter circuit. The frequency is 32-36KHz, the inverter circuit is also connected with a drive circuit, and the drive circuit is connected with a frequency modulation control circuit.

[0025] The frequency of the high-frequency inverter circuit changes ±2...

Embodiment 3

[0030] Such as figure 1 An electronic ballast for a high-pressure sodium lamp is shown, including a filter, a PFC rectifier, an inverter circuit, a high-pressure sodium lamp, an auxiliary power supply, a control circuit and a starter, the output end of the filter is connected to the PFC rectifier, and the output end of the PFC rectifier is connected to the inverter circuit The two ends of the inverter circuit are connected to the high-pressure sodium lamp, the starter is connected to the two ends of the high-pressure sodium lamp, the control circuit is respectively connected to the PFC rectifier and the inverter circuit, the auxiliary circuit is connected to the control circuit, and the inverter circuit is a high-frequency inverter circuit. The frequency is 33-35KHz, the inverter circuit is also connected with a drive circuit, and the drive circuit is connected with a frequency modulation control circuit.

[0031] The frequency of the high-frequency inverter circuit changes ±1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com