Master cylinder

A technology of active cylinder and clutch, applied in the direction of fluid drive clutch, non-mechanical drive clutch, fluid pressure actuating device, etc., can solve problems such as system damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

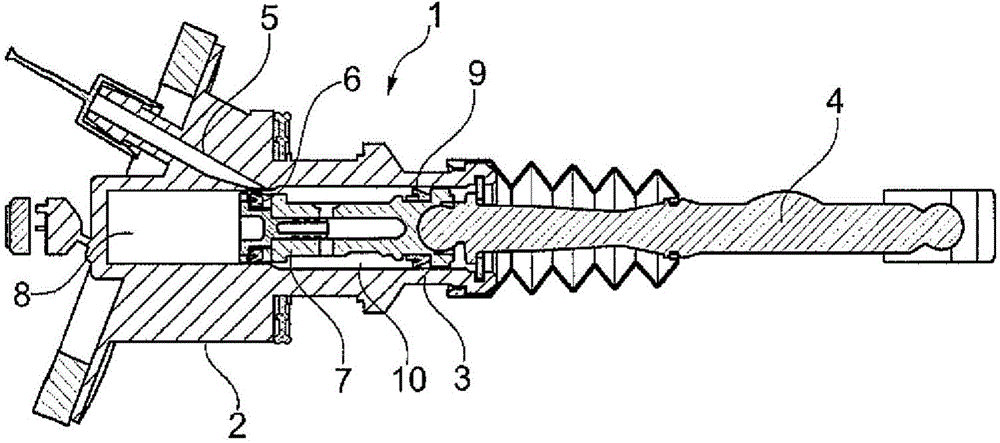

[0023] figure 1 A master cylinder 1 in the prior art is shown. The master cylinder 1 has a master cylinder housing 2 in which a piston 3 is guided so as to be axially displaceable. The piston 3 is pressed in axial direction via a piston rod 4 into the cylinder interior, for example by a pedal (not shown). The flow pipe 5 is connected with a flow container (not shown). The piston has a piston seal 6 which is fastened to the piston by means of a piston insert 7 and delimits a pressure chamber 8 in the cylinder. The secondary piston seal 9 delimits a follower chamber 10 . A pressure line (not shown) leads from the pressure chamber 8 to a slave cylinder (not shown).

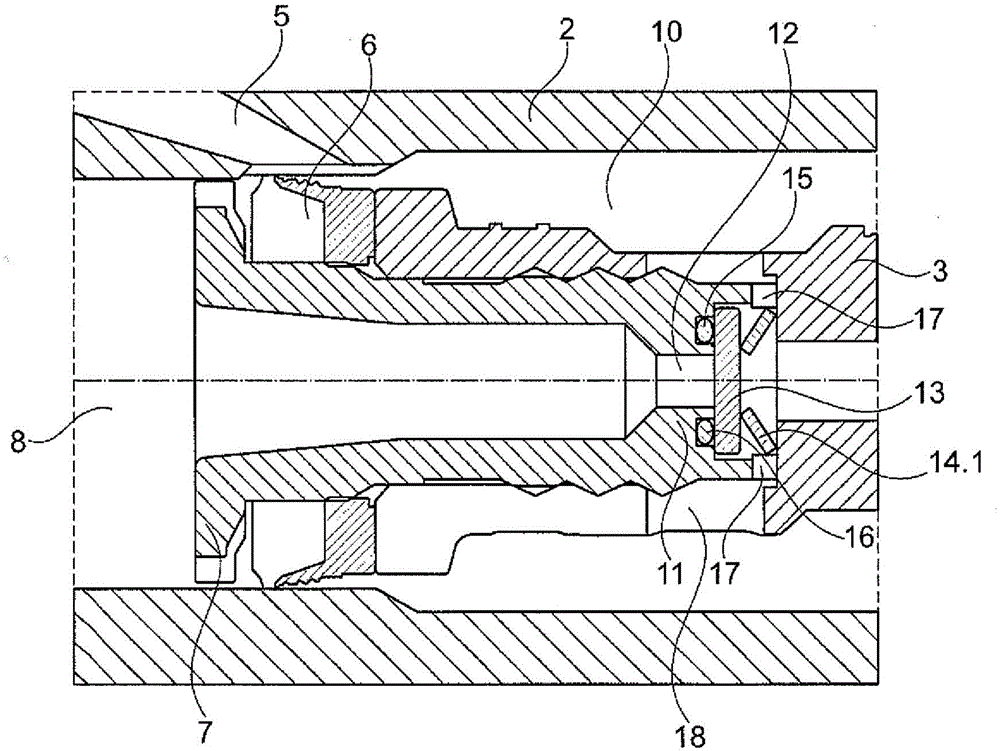

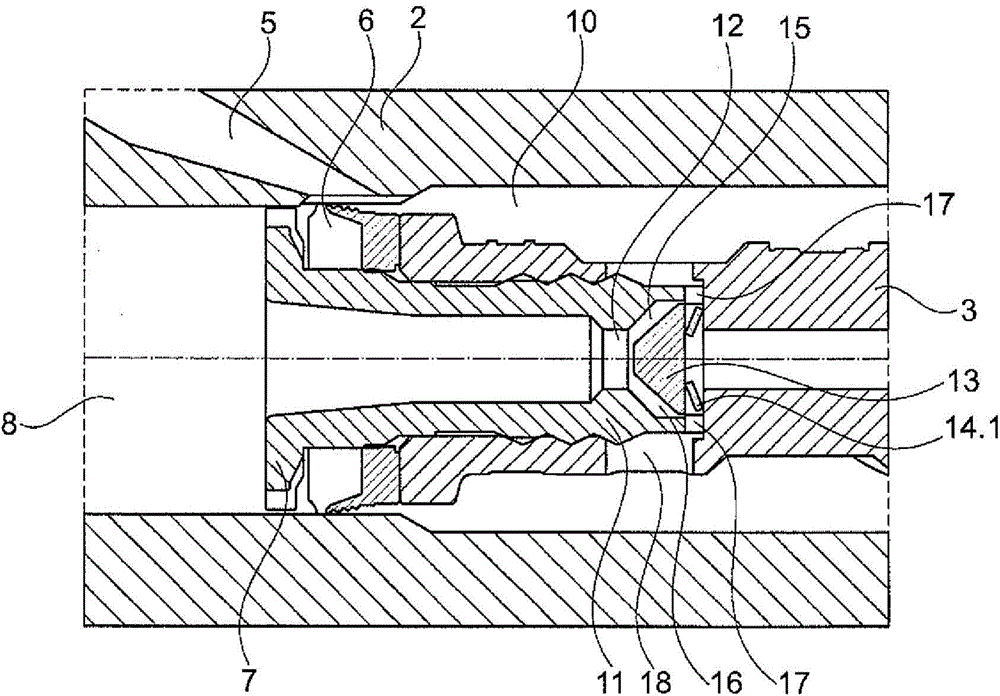

[0024] figure 2 shows a part of the master cylinder 1 according to the invention, which is in principle compatible with figure 1 Active cylinders in the prior art are constructed similarly. In this embodiment, the piston insert 7 extends to an overload valve 11 . The overload valve 11 has a bore 12 which ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com