Ring seal assembly of bidirectional metal seal structure

A ring sealing and metal sealing technology, which is applied in the directions of sealing/isolation, wellbore/well parts, earthwork drilling and mining, etc., can solve the problems of complicated and time-consuming loading and unloading procedures, affecting sealing performance, and damage to sealing parts, etc., and achieves compact structure, Effects of improving efficiency and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

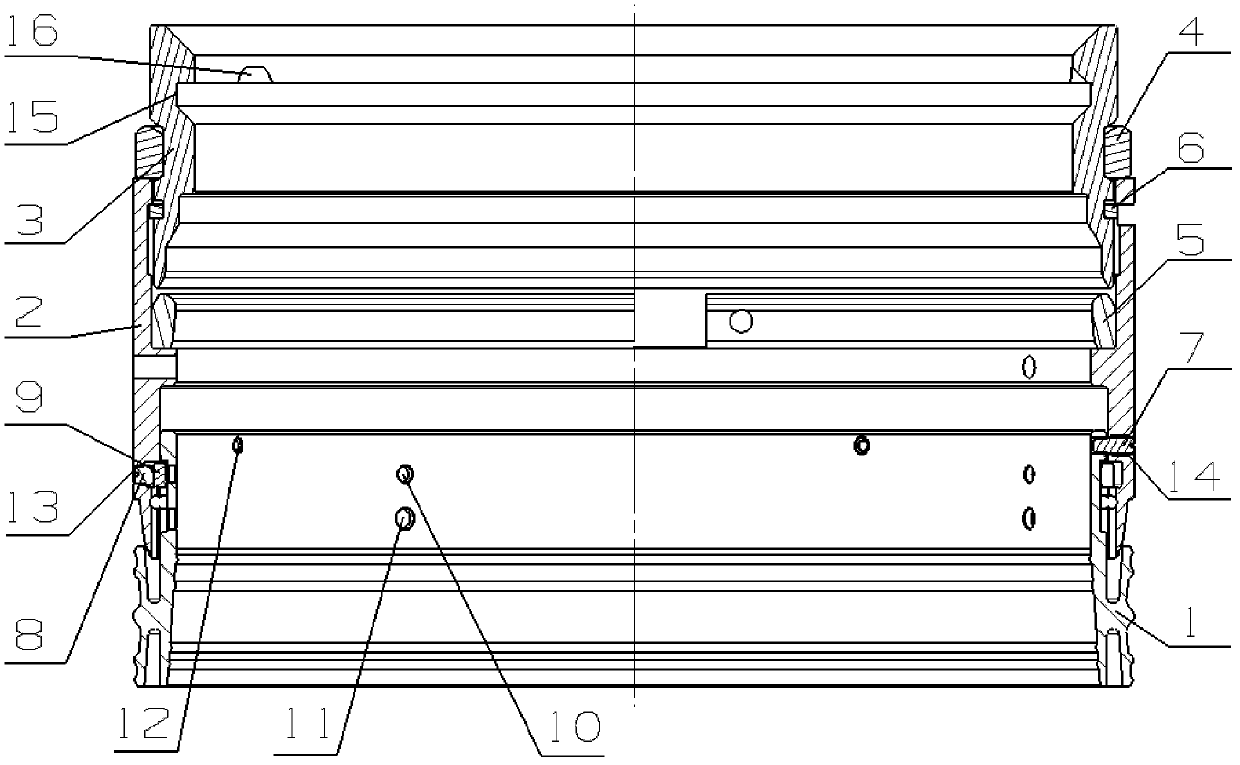

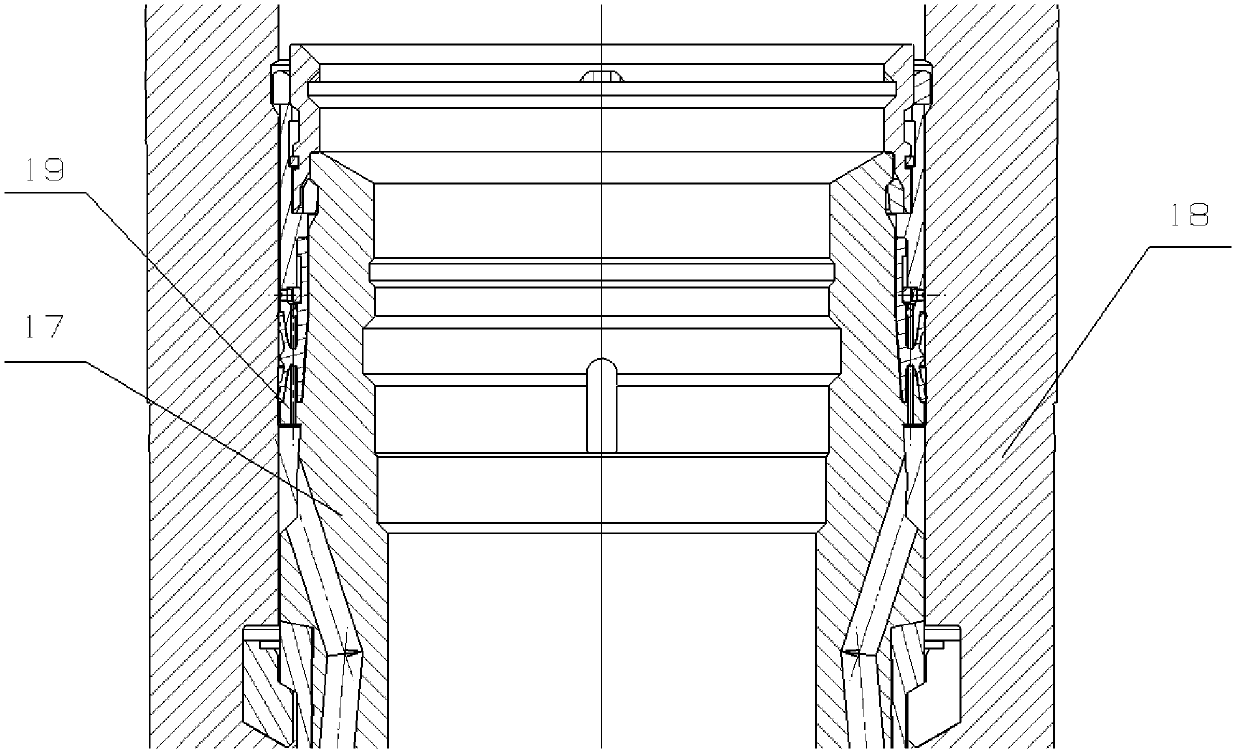

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

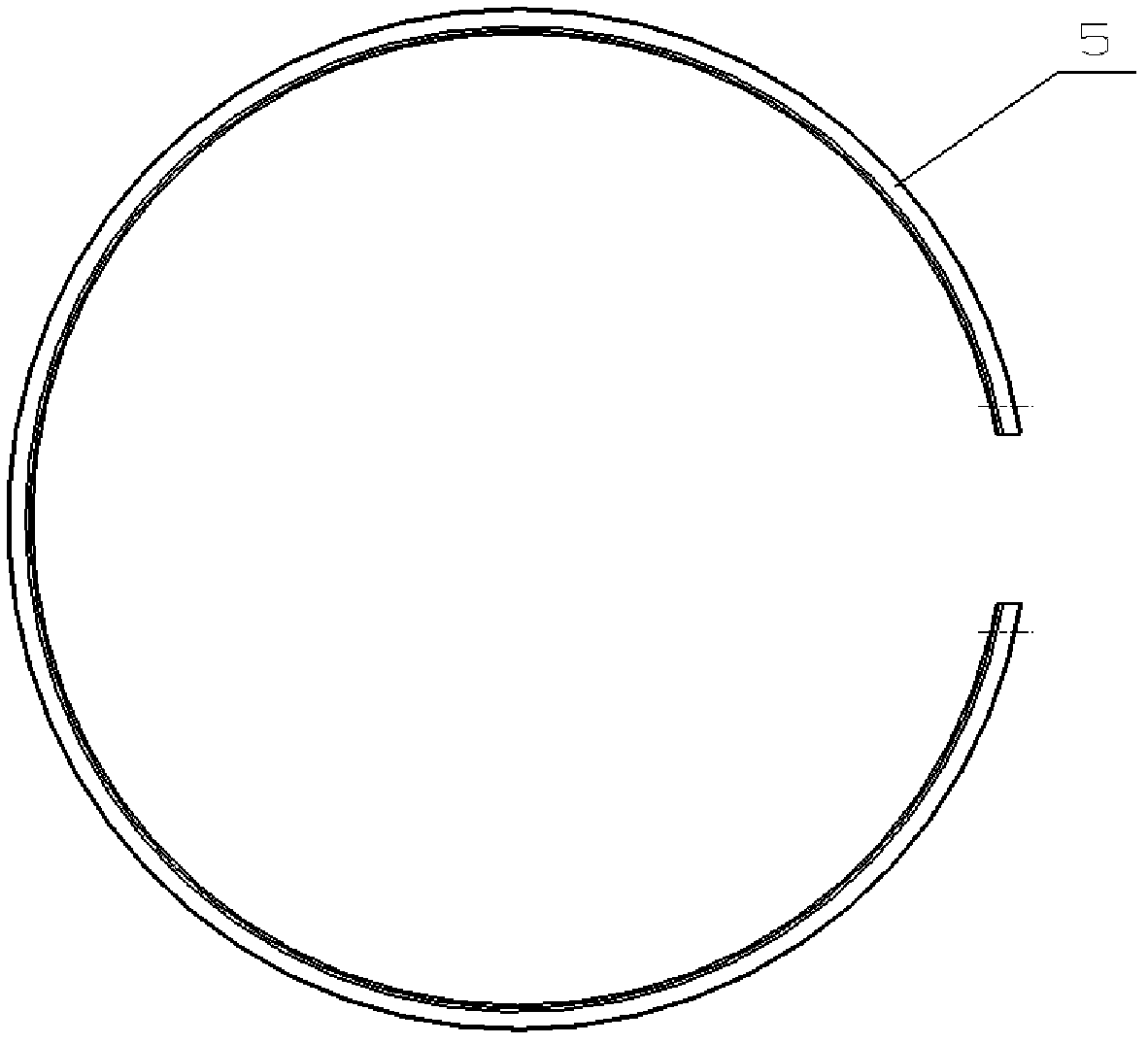

[0017] It includes a sealed driving sleeve 2, the upper part of the inner hole of the sealed driving sleeve is socketed with the lower part of the locking sleeve 3, and the lower part of the inner hole of the sealed driving sleeve is socketed with the upper part of the metal sealing ring 1; the outer peripheral upper part of the locking sleeve is provided with a ring The groove is equipped with a wellhead lock ring 4. The wellhead lock ring is an elastic ring with one side cut, which is tightly hooped in the ring groove. The upper end of the ring groove is inclined outward by 40-60° to form a conical surface. The wellhead lock The inner side of the upper end face of the ring is also provided with corresponding chamfers, so that when the locking sleeve goes down, the well head lock ring escapes from the ring groove outwards, the lower end face of the well ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com