Three-section synchronous hidden slide rail

A technology of slide rail and middle rail, which is applied in the field of three-section synchronous hidden slide rail, which can solve the problems of gears and upper and lower racks deviating from the correct position, affecting the use effect, and damaging racks and gears, etc., to achieve convenient disassembly and replacement, high performance Reliable, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

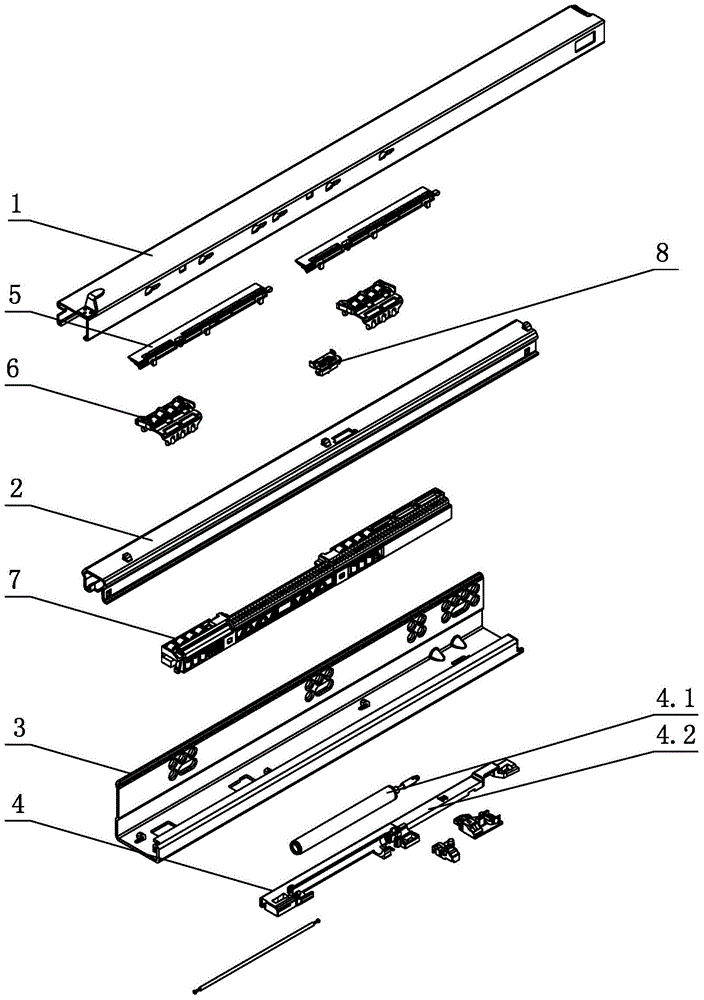

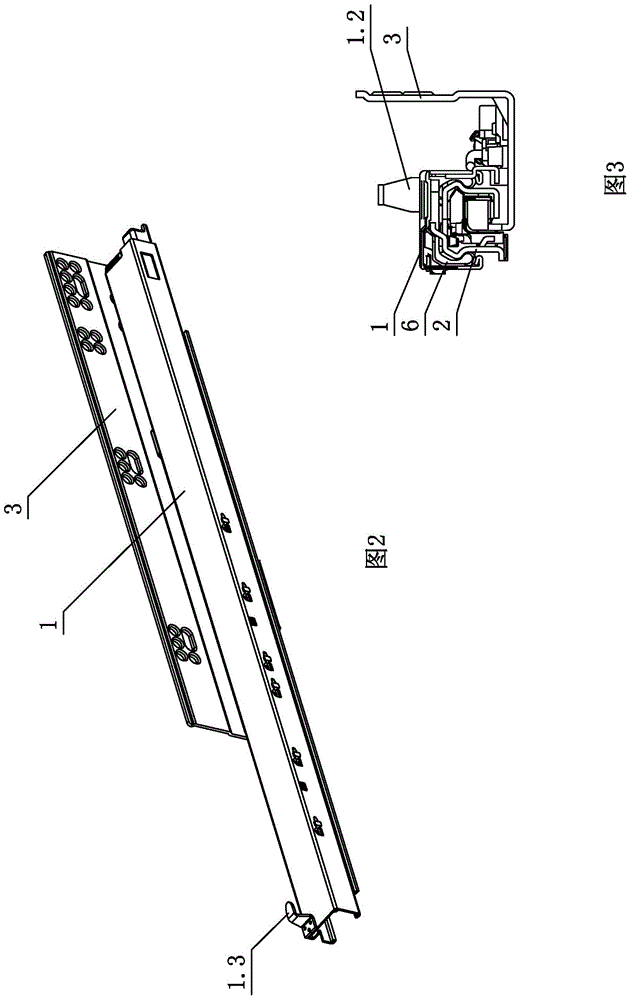

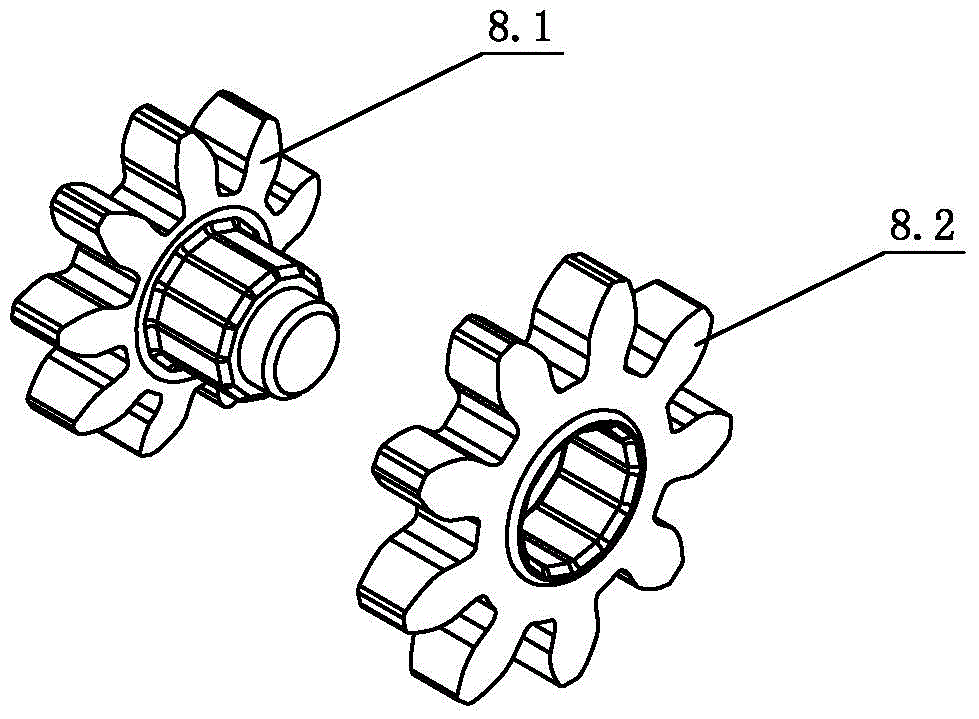

[0038] see Figure 1-3 , the three sections hide slide rails synchronously, including movable rail 1, middle rail 2, fixed rail 3 and damping mechanism 4. An upper rack 5 and an upper roller cage 6 with rollers are arranged between the movable rail 1 and the middle rail 2; a split lower roller cage 7 with rollers is arranged between the middle rail 2 and the fixed rail 3, and its surface There is a rack; a gear assembly 8 is meshed between the upper rack 5 and the lower roller cage 7, and the gear assembly 8 controls the synchronous or misplaced operation of the movable rail 1 and the middle rail 2 according to the magnitude of the force; the movable rail 1, the middle rail 2 and the damping mechanism 4 are assembled on the fixed rail 3 respectively. This slide rail is symmetrically arranged on both sides in the cabinet cavity, and it is fixed through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com