Screw type degassing sewage disposal device

A technology of spiral type and sewage discharger, which is applied in the direction of chemical instruments and methods, filtration separation, magnetic separation, etc., can solve the problem of poor exhaust valve effect, increased pressure loss of filter screen clogged area, and easy corrosion of equipment and components. Damage and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

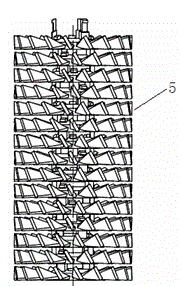

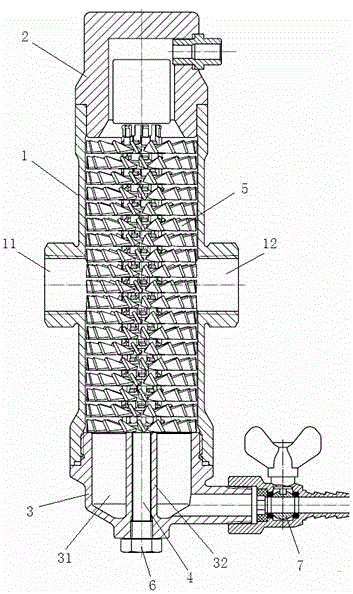

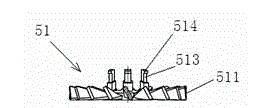

[0017] like Figure 1 to Figure 5 As shown, the present invention includes a cylindrical housing 1, with water inlet and outlet ports 11, 12 arranged on both sides of the middle of the housing, an automatic exhaust valve 2 connected to the top, and a bottom cover 3 provided with a sedimentation chamber 31 connected to the bottom, and the bottom cover settles A sleeve 32 is provided at the center of the chamber 31, and the sleeve 32 extends upwards into the inner cavity of the housing 1. The top of the sleeve 32 is flush with the water inlet and outlet 11, 12 of the housing, and a magnetic rod 4 is arranged inside the sleeve 32. The magnetic rod adopts Made of strong magnetic material, the casing 32 in the inner cavity of the housing is equipped with a spiral filter element 5, the spiral filter element 5 is formed by connecting a plurality of impellers 51 with a central hole in series, and the outer peripheral wall of the impeller 51 center hole Spiral blades 511 with evenly di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com