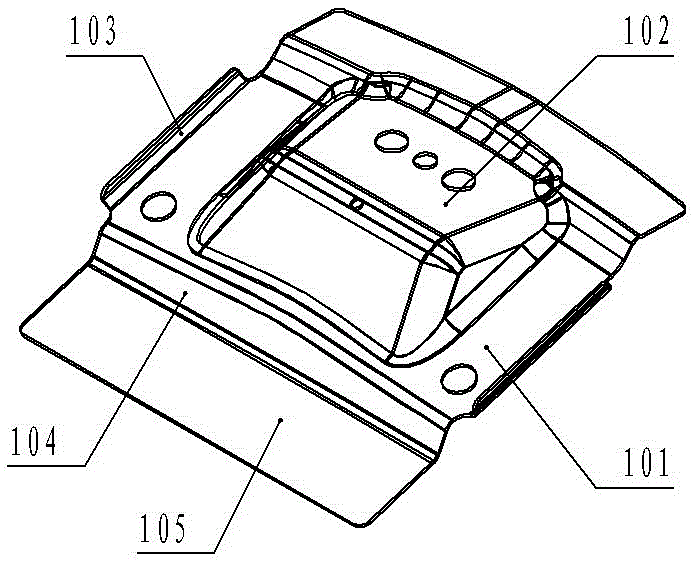

Auto rear door lock reinforcement plate stamping die

A technology of stamping die and reinforcing plate, applied in the field of stamping die manufacturing, can solve problems such as inaccurate positioning of workpieces, and achieve the effects of improving production efficiency, protecting molds, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

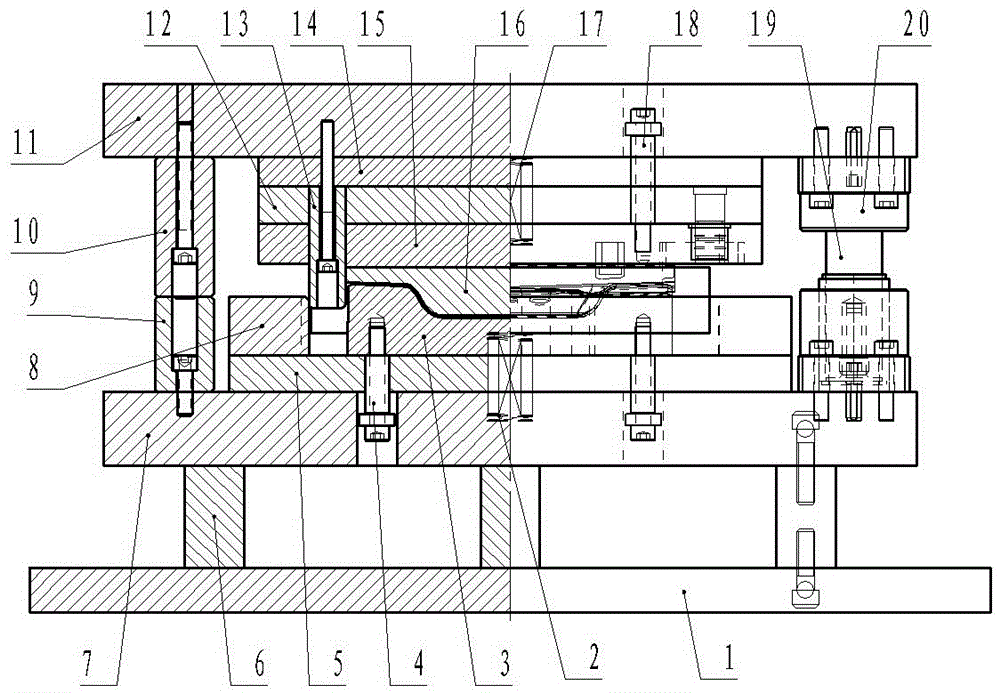

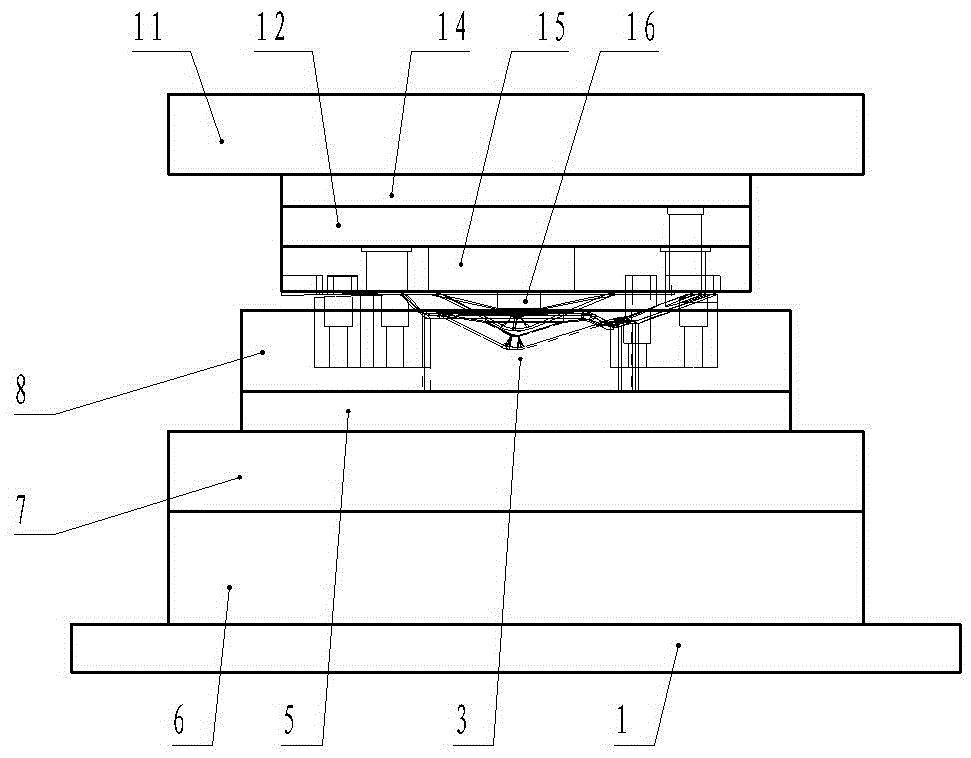

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

[0015] Such as figure 2 , image 3 The shown stamping die for the reinforcement plate of the rear door lock of an automobile includes an upper mold base 11 and a lower mold base 7, the lower mold base 7 is installed on the bottom plate 1 through the die feet 6, and the lower end of the upper mold base 11 is sequentially equipped with an upper backing plate 14. Upper splint 12, upper template 15 and forming punch 16, flanging punches 13 are installed on both sides of forming punch 16, and flanging punches 13 pass through upper template 15, upper splint 12 and upper die base 11 Connected, the upper splint 12 is equipped with fourteen upper unloading springs 17 whose upper end passes through the upper backing plate 14 and the upper die base 11, and the lower end extends into the upper die base 15. 14. Four upper unloading bolts 18 connecting the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com