Foamed aluminum automobile anti-explosion oil tank

A technology of automobile fuel tank and aluminum foam, applied in the direction of the substructure, etc., can solve the problems of fuel tank rupture, fuel leakage, fuel outflow, etc., and achieve the effect of improving safety and slowing down the explosion shock wave

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better illustrate the present invention and facilitate understanding of the technical solutions of the present invention, typical but non-limiting examples of the present invention are as follows.

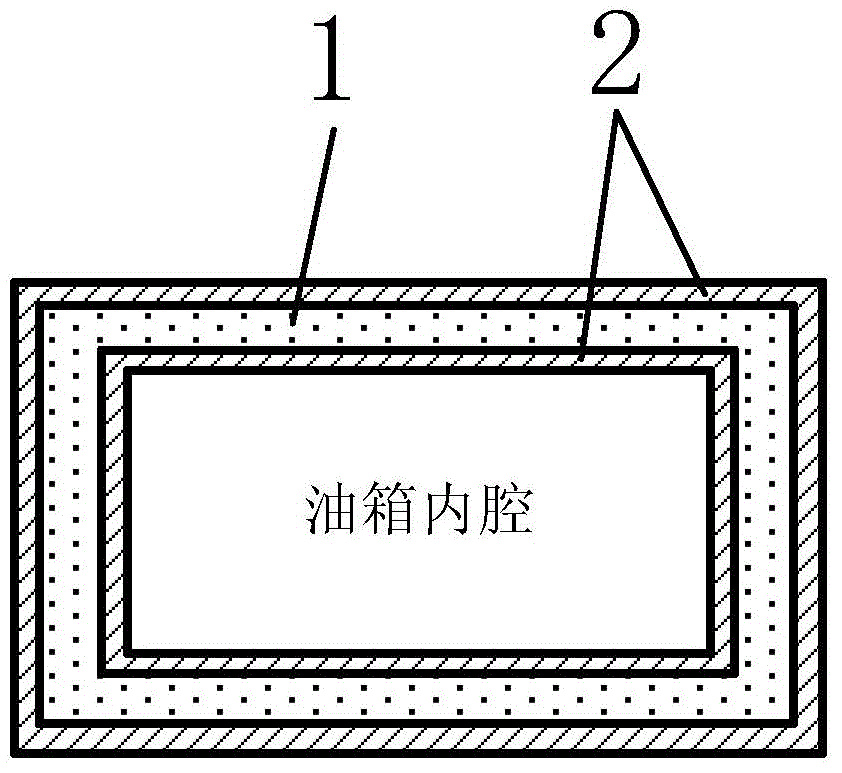

[0017] The wall of the automobile fuel tank is made into a sandwich structure, and a new type of foamed aluminum material is filled between two layers of steel plates (2) to form a foamed aluminum layer (1).

[0018] The composite structure composed of the steel plate layer (2) and the foamed aluminum layer (1) can be multi-layered according to the requirements of the explosion-proof grade. ability.

[0019] This foamed aluminum layer sandwich structure has the characteristics of light weight, high specific stiffness, and good vibration reduction (damping) performance. When the fuel inside the fuel tank explodes, it has the effect of slowing down the explosion shock wave, reducing or even preventing the explosion from causing damage to surrounding people ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com