Separation device for canned food

A separation device and canned food technology, applied in the field of mechanical transmission, can solve the problems of high cost of separation device, inability to pick out empty cans, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

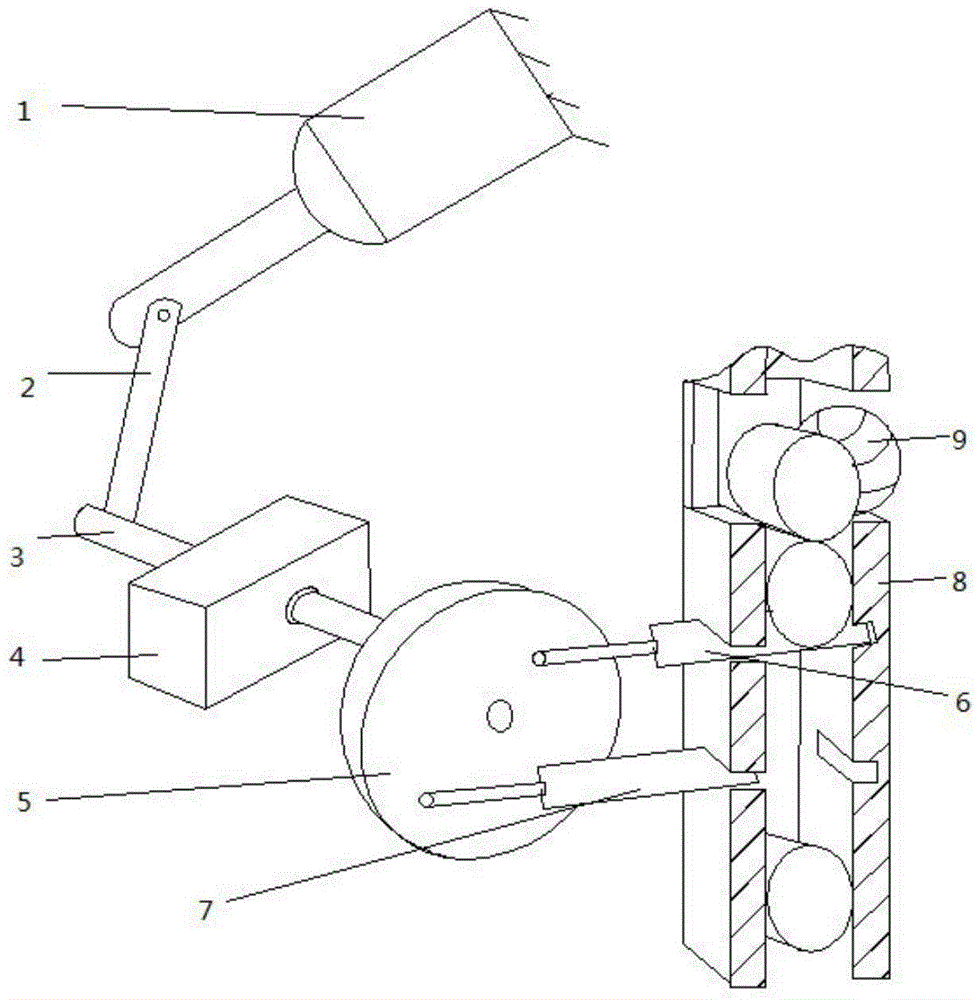

[0011] The reference signs in the description of the drawings are: cylinder 1; linkage plate 2; bracket 3; transmission shaft 4; rotary table 5; first baffle 6; second baffle 7;

[0012] Such as figure 1 As shown, the technical solution provides a separation device for canned food, including a transmission mechanism and a conveying mechanism. The cylinder 1 is hinged, and the other end is fixedly connected with the transmission shaft 4, the transmission shaft 4 is fixedly connected to the center of the turntable 5, and the middle part of the transmission shaft 4 is movably connected to the support 3. In this way, driven by the cylinder 1, the rotary table 5 is reciprocated and rotated. A first baffle 6 and a second baffle 7 for receiving cans are correspondingly hinged on the surface of the rotary table 5 . Wherein, when any baffle plate travels to the rightmost end along with the rotary table 5, it is necessary to ensure that the baffle plate can seal the material delivery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com