A plunger type centralizer with large variable diameter

A technology of plunger type and centralizer, which is applied in the direction of drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of time-consuming and economical cost, complex process, large size of centralizer, etc., and achieve large variable diameter range, Stable centering force, simple and reliable downhole control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

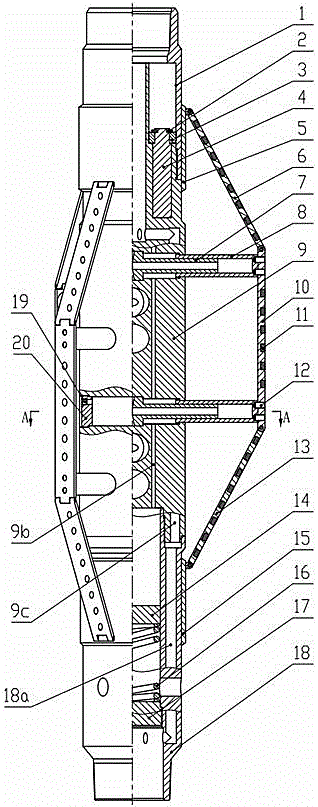

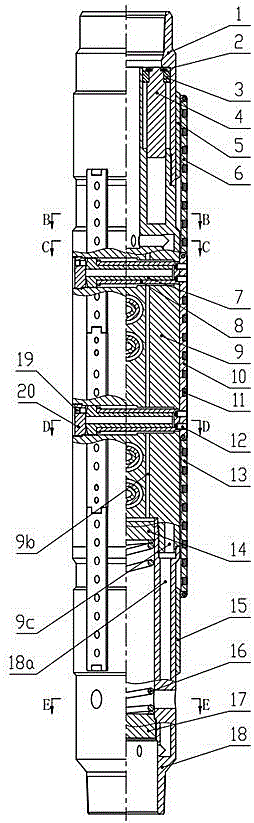

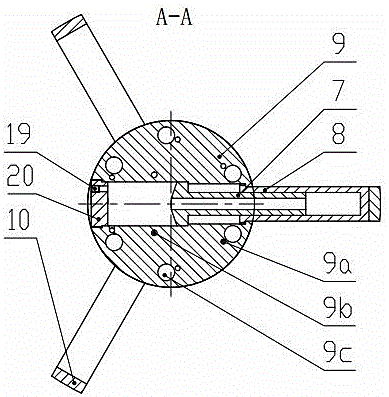

[0015] Such as figure 1 and figure 2 As shown, a plunger-type large-diameter centralizer of the present invention includes an upper joint 1, a retaining spring 2, a plunger seat 3, a plunger 4, an upper sliding sleeve 5, an upper connecting rod 6, a centering cylinder mandrel 7, Centralizing cylinder 8, main cylinder 9, centralizing body 10, cutting teeth 11, screw a12, lower connecting rod 13, floating piston 14, sliding sleeve 15, spring 16, packing plug 17, lower joint 18, screw b19, sealing oil Seat 20; its structural features are: a step is arranged on the upper part of the main cylinder body 9, six plunger holes are arranged axially on the step surface, the six plunger holes are evenly distributed in the circumferential direction, and the six plunger 4 are respectively inserted into the main cylinder body 9. In the six plunger holes, the upper part of the plunger 4 is provided with a small-diameter section, and the small-diameter section is provided with an annular gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com