A tunnel lining trolley

A technology for lining trolleys and tunnels, which is applied in the field of variable-span tunnel lining trolleys, can solve the problems of not being able to meet the requirements for lining the contours of widened-section tunnels, increase construction difficulty, etc., and achieve convenient construction and disassembly operations and improve surface construction The effect of improving quality and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

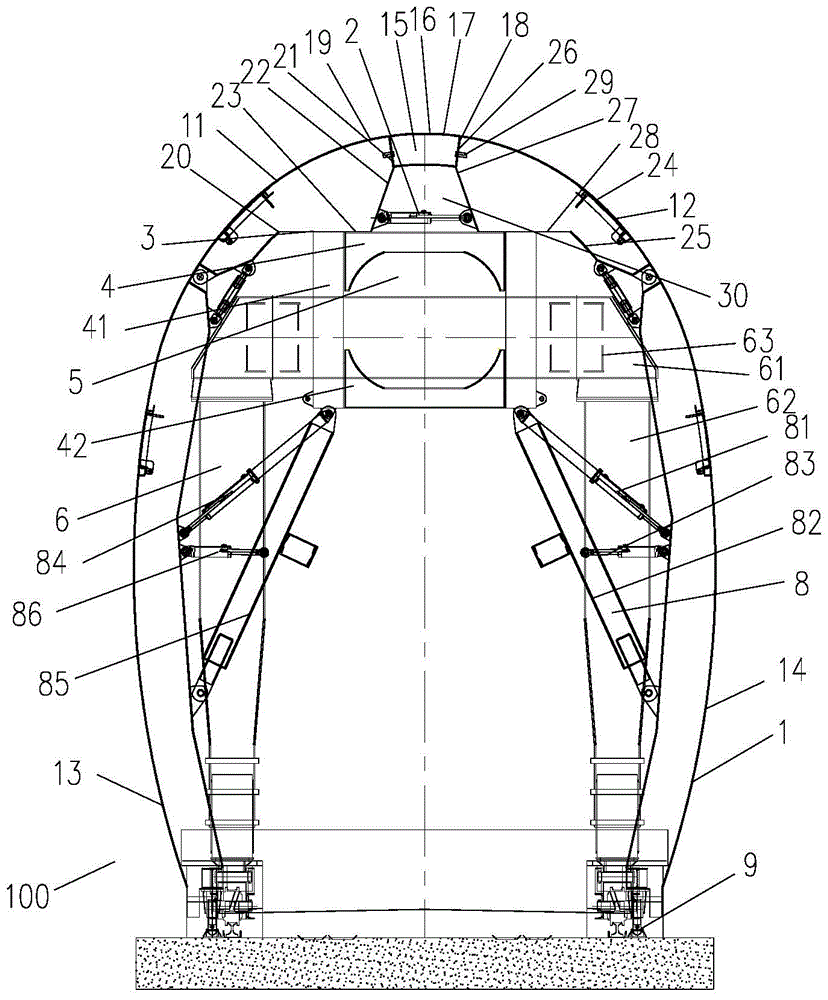

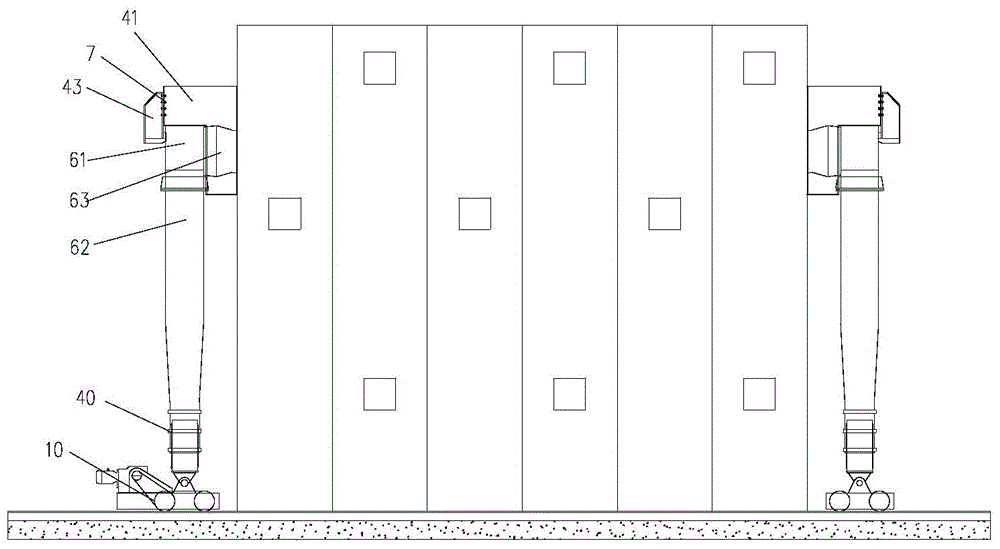

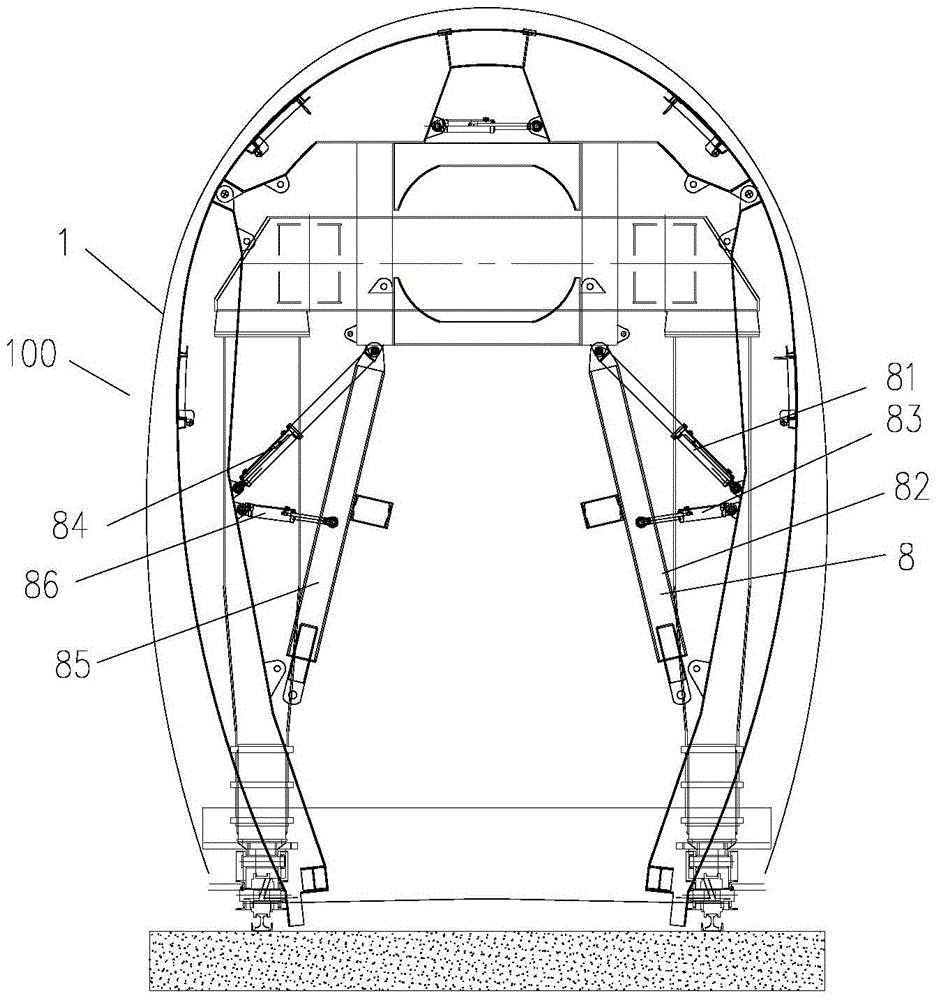

[0032] The present invention will be further described below in conjunction with accompanying drawing.

[0033] like figure 1 As shown, the tunnel lining trolley 100 includes a formwork assembly 1 matching the tunnel profile. The template assembly 1 includes a left top template 11 , a right top template 12 , a left template 13 and a right template 14 . Wherein, the left top template 11 and the right top template 12 are arranged oppositely, a gap 15 is formed between the upper ends of the two, and the distance of the gap 15 in the transverse direction is adjustable. The left template 13 and the right template 14 are arranged oppositely, and the left template 13 and the right template 14 are connected with the lower ends of the left top template 11 and the right top template 12 respectively. The formwork assembly 1 also includes a top formwork 16 , which is detachably connected to the left top formwork 11 and the right top formwork 12 to adapt to the change of the gap 15 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com