Integrated collaborative working device for pipelines in lng storage tank and vertical maintenance ladder

A technology of collaborative work and storage tanks, used in fixed-capacity gas storage tanks, ladders, gas/liquid distribution and storage, etc., can solve the problem that the inner tank wall cannot be welded and constructed, and achieve increased resistance to low temperature shrinkage and liquid impact. Load capacity, saving construction period and reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

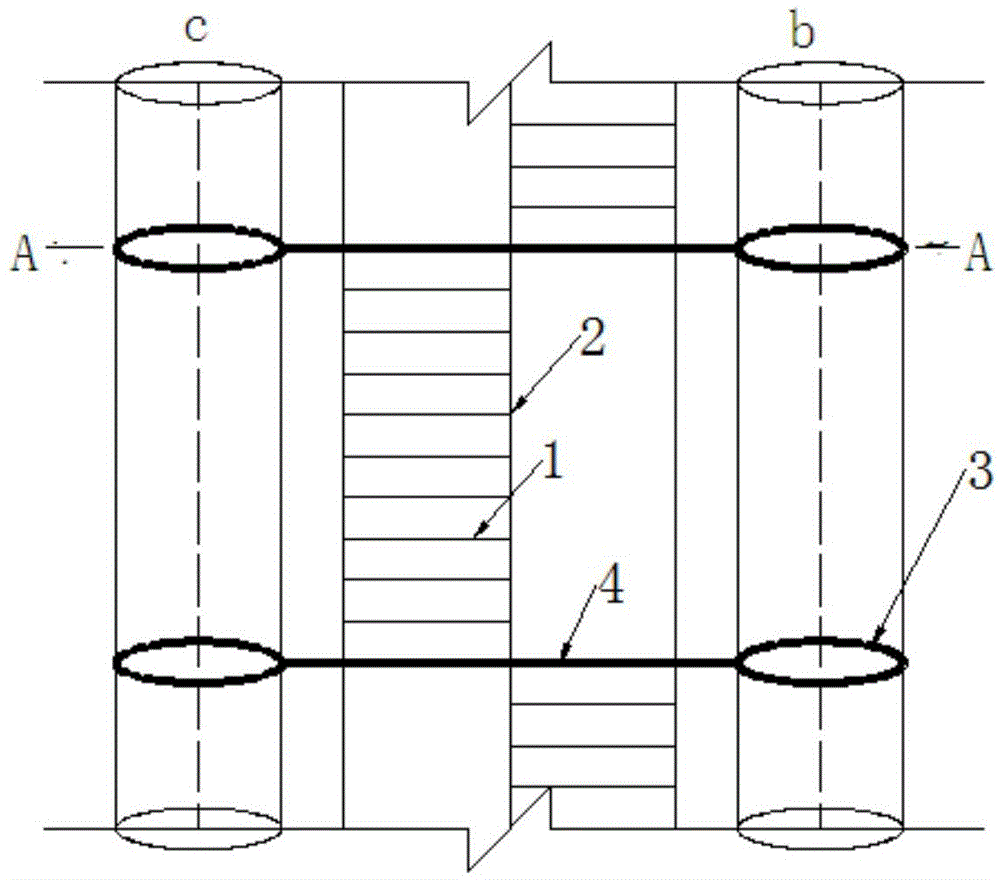

[0025] Such as figure 1 As shown, it is the integrated cooperative working device of the pipeline in the LNG storage tank and the vertical maintenance ladder of the present invention, which includes 3 LNG storage tank pipelines a, b and c arranged in the LNG storage tank, and the vertical maintenance ladder, wherein the LNG storage tank The tank pipelines a, b and c are arranged at a distance of 2m from the inner tank wall of the LNG storage tank. The installation method is: the plane where the LNG storage tank pipelines b and c are located is close to the inner tank wall.

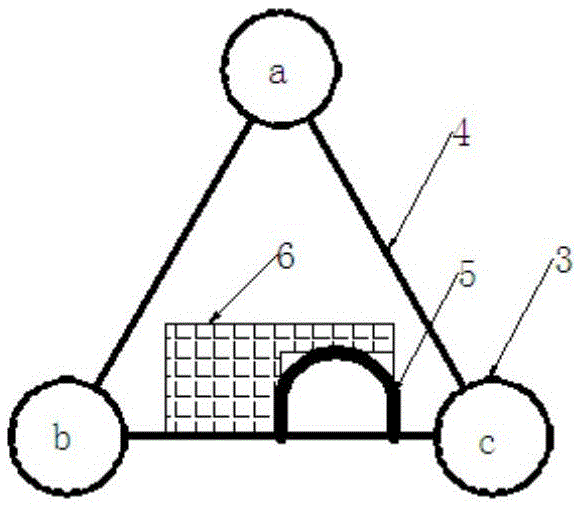

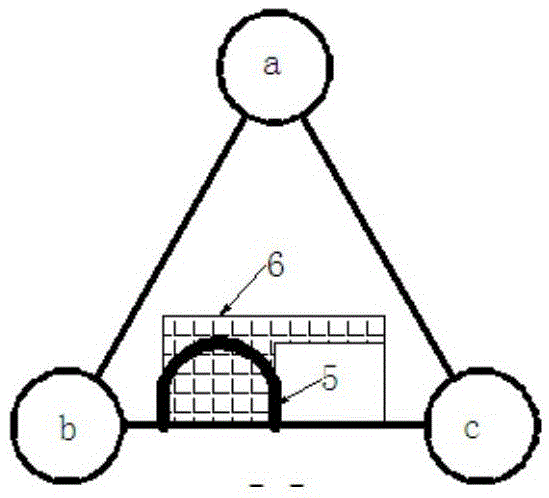

[0026] Such as figure 2 with image 3 As shown, the connection lines of the three LNG storage tank pipelines a, b and c along the horizontal direction are equilateral triangles, that is, the shape of "pin", and the three LNG ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com