Steel pipe roundness measuring instrument

A technology of roundness measuring instrument and steel pipe, which is applied in the direction of measuring devices and instruments, can solve problems such as difficult to meet online steel pipe measurement, and achieve the effect of simple structure, fast online measurement, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

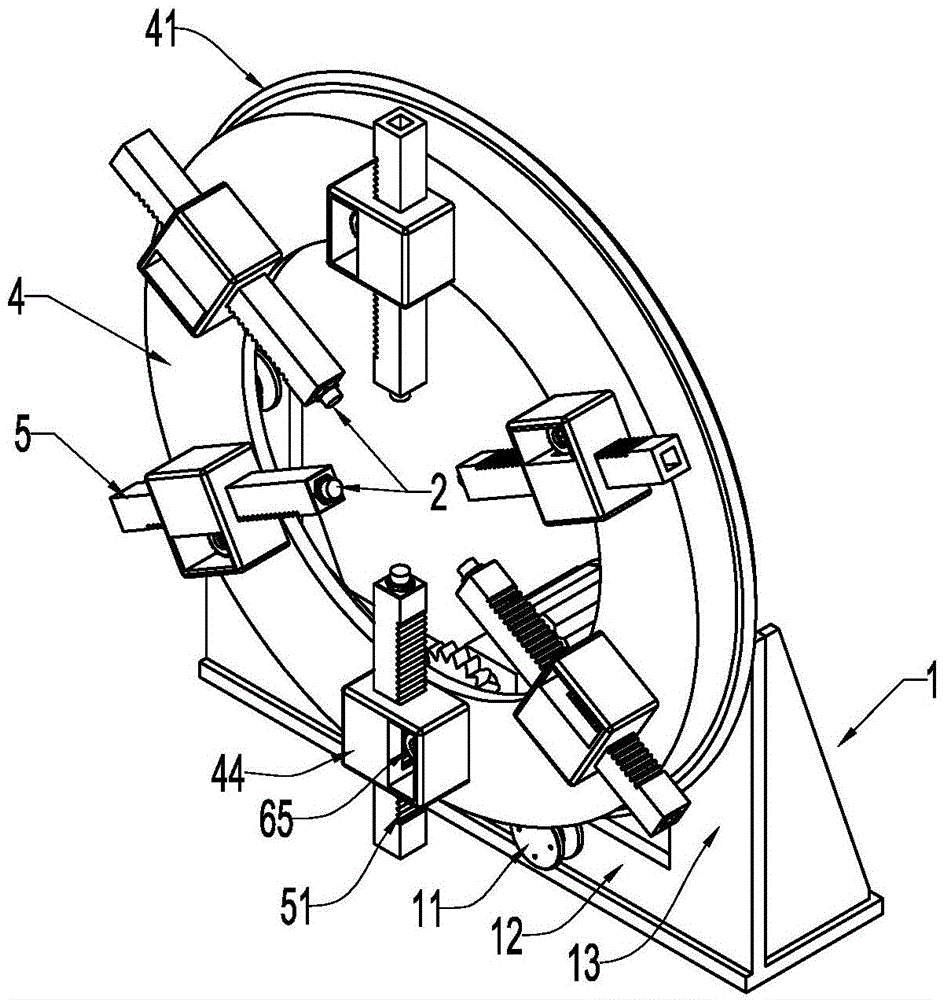

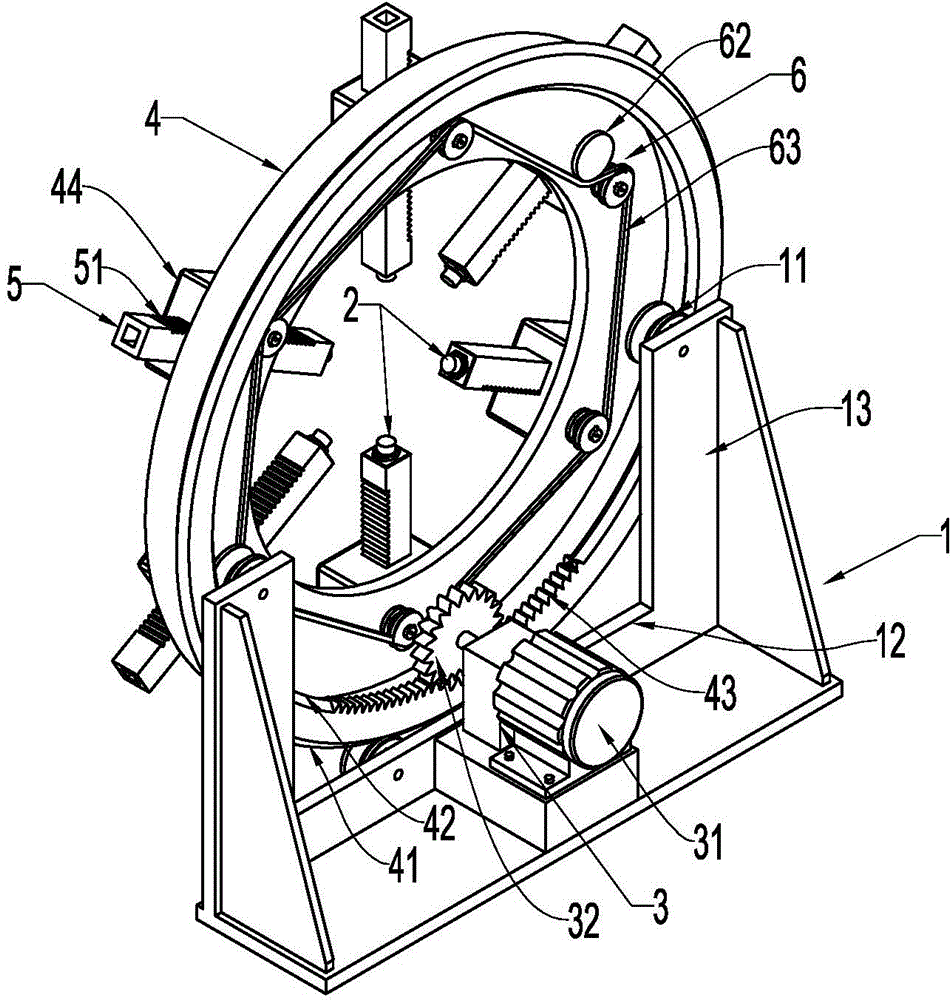

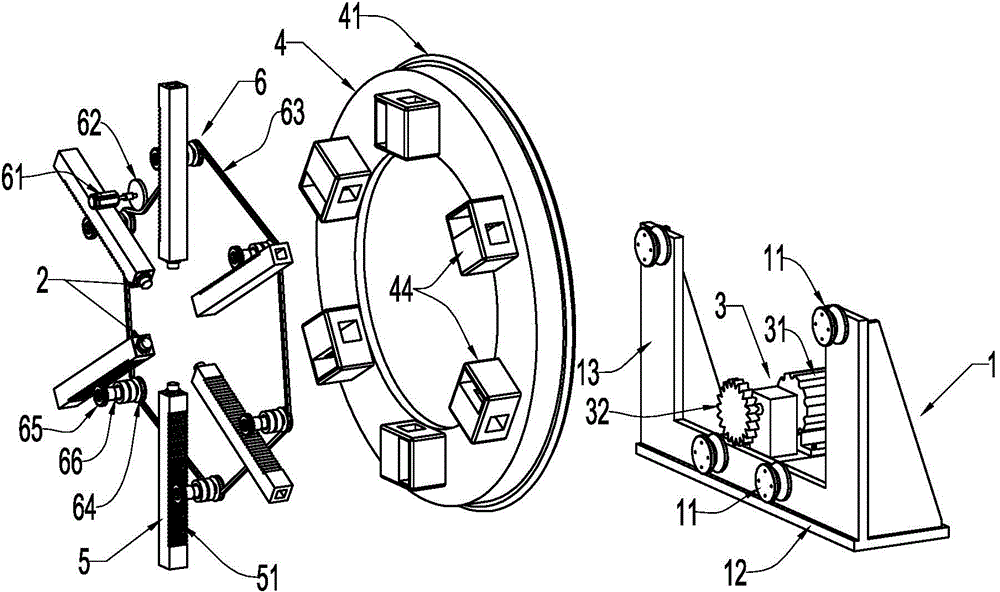

[0023] refer to figure 1 , figure 2 and image 3 , a steel pipe roundness measuring instrument, comprising a frame 1, a displacement sensor 2 and a data acquisition and processing system; a plurality of sheaves 11 and a power mechanism 3 are installed on the frame 1, a reference ring 4 is installed on the frame 1, and It is slidably supported by a plurality of sheaves 11; more specifically, an outer ring rail 41 and an inner ring rail 42 are provided on the ring of the reference ring 4 facing the frame 1, and the inner ring rail 42 is processed with teeth Section 43, the central angle of the tooth section 43 is not more than 180 degrees; and the frame 1 is a floor-to-ceiling U-shaped structure, including a conjoined bottom beam 12 and two side columns 13, and four sheaves 11 are positioned on the symmetrical axis On the vertical side, two sheaves 11 are on the bottom beam 12, supported on the outer ring rail 41 at the lower part of the reference ring 4, and the other two sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com