Experimental device for measuring petrochemical process parameters based on safety interlock system

A safety interlocking and technological process technology, applied in the direction of measuring devices, instruments, etc., can solve the problems that the complete set of experimental equipment has yet to be developed, and achieve the effect of increasing the valve performance test platform, compact structure, and high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

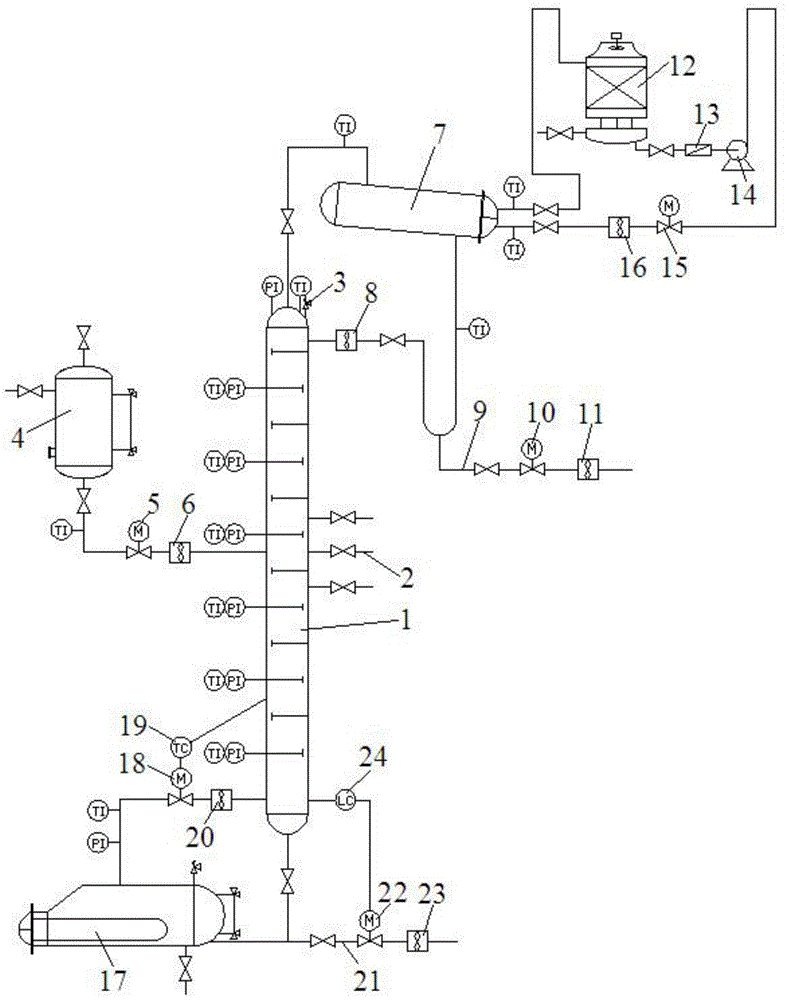

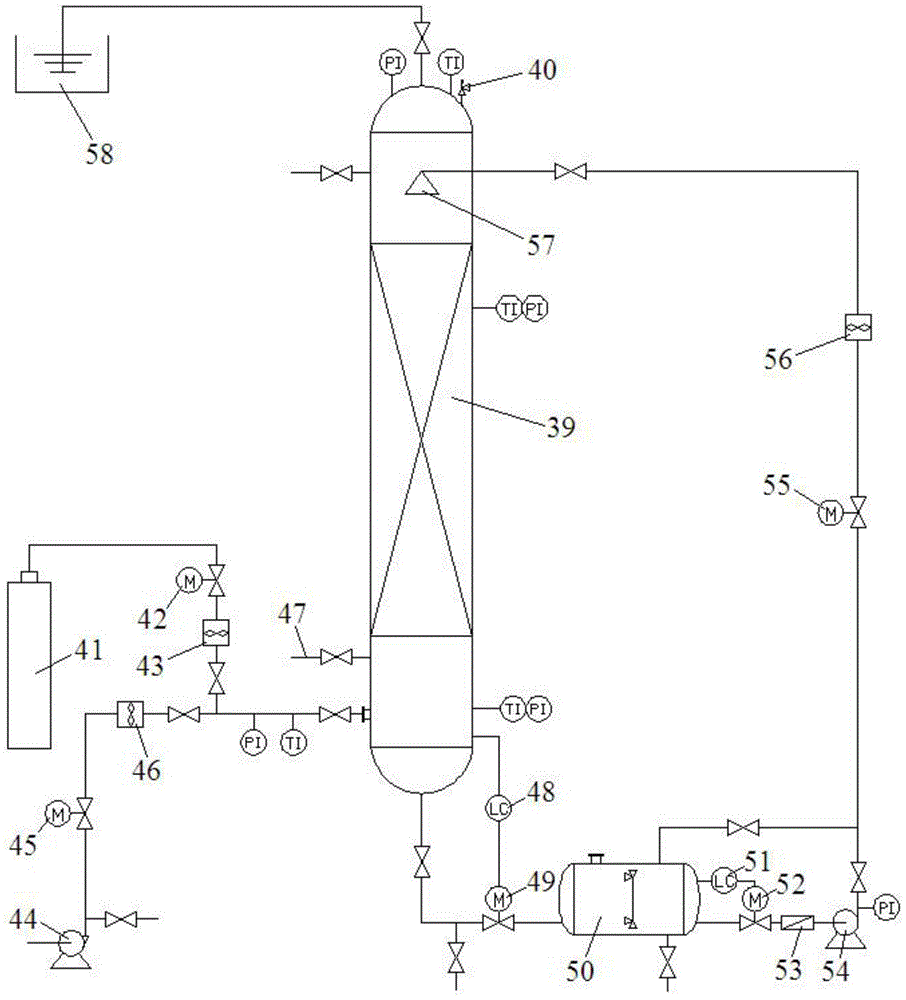

[0023] In this embodiment, the inner diameter of the sieve tray rectification tower 1 is 104 mm, the number of trays is 12, the diameter of the sieve holes of the trays is 2 mm, and the distance between the sieve holes arranged in an equilateral triangle is 8 mm. The inner diameter of the packed absorption tower 39 is 210 mm, and the height of the unsegmented packing layer inside is 1 m.

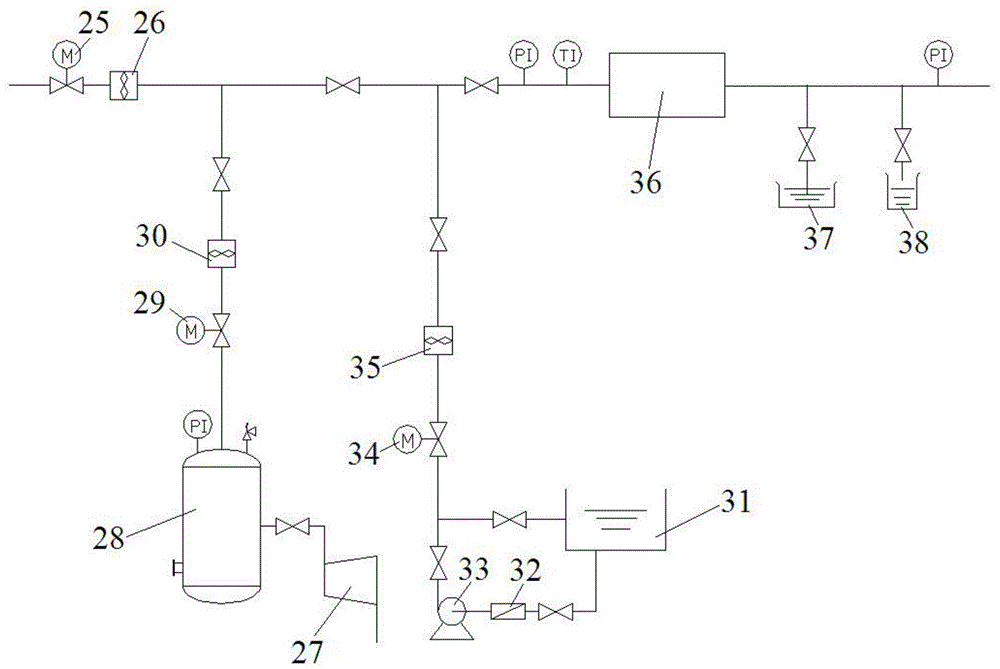

[0024] refer to Figure 1 to Figure 3 , an experimental device for measuring petrochemical process parameters based on a safety interlock system, including a sieve plate rectification tower device, a packed absorption tower device, a general valve performance test device, and a measurement and control system for controlling the operation of the above devices,

[0025] The sieve plate rectification tower device comprises a sieve plate rectification tower 1, a feeding system, a reflux system, a steam generation system at the bottom of the tower, a product outlet pipe 9 and a raffinate outlet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com