Large-target-surface high-precision mold high-definition zooming monitoring lens

A high-precision, large-target technology, applied in installation, optics, instruments, etc., can solve the problems of not meeting the needs of the high-end market and uneven performance indicators, and achieve the effects of short structure length, high resolution, and improved relative aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

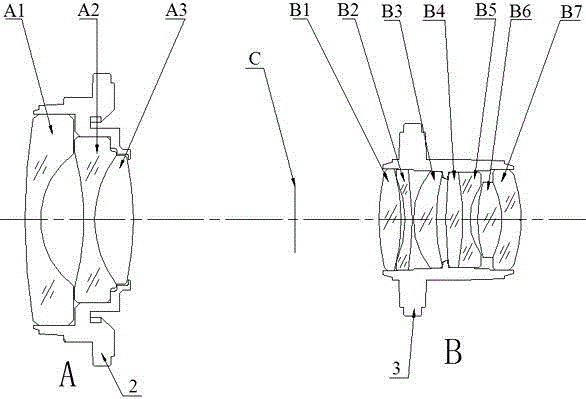

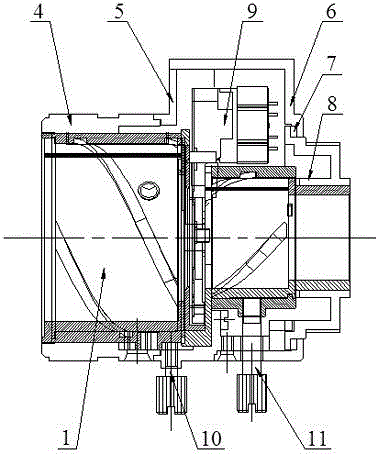

[0021] Such as figure 1 As shown, a high-precision mold high-definition zoom monitoring lens with a large target surface, the optical system of the lens is sequentially provided with a front group A with a negative focal power, an iris diaphragm C, and an optical lens along the incident direction of light from left to right. The focal power of the rear group B is positive, the front group A is sequentially provided with a negative crescent lens A-1 and the first cemented group closely connected by a biconcave lens A-2 and a biconvex lens A-3, and the rear group B is sequentially provided with There are biconvex lens B-1, negative crescent lens B-2, negative crescent lens B-3, the second cemented group consisting of biconvex lens B-4 and biconcave lens B-5, and biconvex lens B-6 and negative crescent lens The third cemented group of lens B-7 close contact.

[0022] In this embodiment, the air gap between the front group A and the rear group B is 22.137 mm, and the air gap betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com