Potato planter

A potato and seeding mechanism technology, applied in the directions of seeder parts, interval-type quantitative seeding machinery, agricultural machinery and implements, etc. Good, cleverly designed, efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

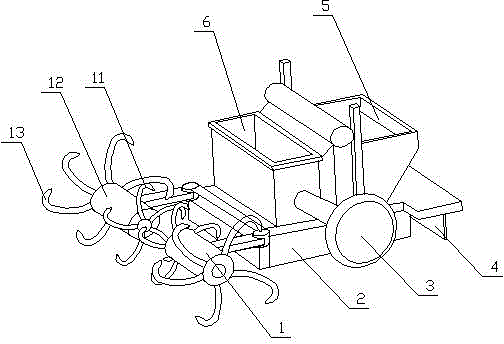

[0013] Such as figure 1 , figure 2 Shown, a kind of potato planter comprises vehicle body 2, fertilizer tank 6, potato storage tank 5, seeding mechanism 7, soil turning device 1.

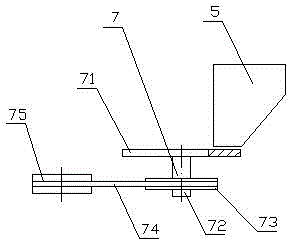

[0014] Potato storage box 5 is installed on the rear portion of vehicle body 2, and the bottom of described potato storage box 5 is provided with sowing port, and seeding mechanism 7 is housed below described sowing port. Such as figure 2 As shown, the sowing mechanism 7 includes a notch-type rotating disk 71, a rotating shaft 72, a transmission belt 74, a small pulley 75, and a large pulley 73. The notch-type rotating disk 71 is provided with a circular feeding hole for potatoes to drop, and the notch The rotating disk 71 is fixed on the rotating shaft 72, and the large pulley 73 is also installed on the rotating shaft 72. The large pulley 73 is connected with the small pulley 75 through the transmission belt 74, and the small pulley 75 is installed on the shaft outlet of the engine. on axis. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com