A micro-cannula Kirschner wire fixation device for metacarpal bone fracture fixation

A fixation device and metacarpal bone fracture technology, applied in the field of medical equipment, can solve the problems of functional exercise, large trauma, and injury affecting patients, and achieve the effects of early functional exercise, small trauma, and small blood supply damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

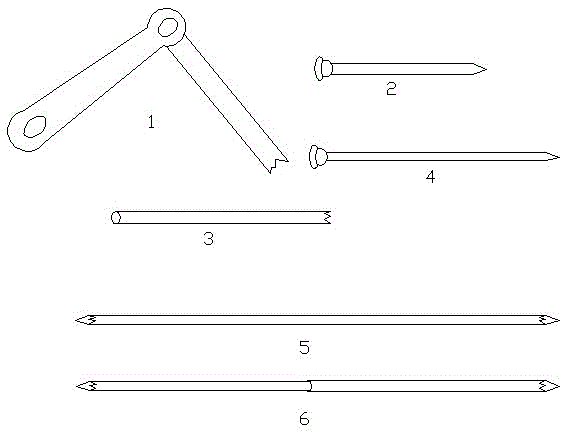

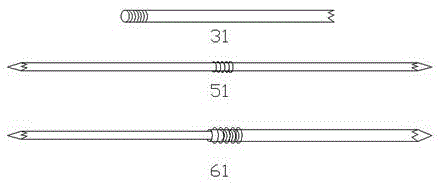

[0018] Such as figure 2 , The first hollow cylindrical miniature sleeve 31 with internal thread at the end and serrated front end, the first Kirschner wire 51 with puncture head with external thread at the end, the two threads are consistent, the first Kirschner needle with puncture head 51 extends into the first micro-cannula 31, so that one end of the first Kirschner wire 51 with a puncture head coincides with the front end of the first micro-cannula 31, and the middle part is screwed into a whole through a thread to form the first micro-cannula Kirschner wire 61.

Embodiment 2

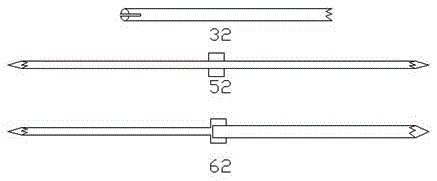

[0020] Such as image 3 , A second hollow cylindrical miniature sleeve 32 with a serrated front end with jaws at the end, a second Kirschner wire 52 with a puncture head with a wedge at the end, and a second Kirschner wire 52 with a puncture head extending into the first In the two micro cannulas 32, one end of the second Kirschner wire with a puncture head is overlapped with the front end of the second micro cannula 31, and the middle is clamped together to form a whole to form the second micro cannula Kirschner wire 62.

Embodiment 3

[0022] Such as Figure 4 , The third miniature sleeve 33 with external thread, the third Kirschner wire with puncture head 53 with external thread, and the nut 7 with double thread. The front end of the third microcannula 33 overlaps with the front end of the third Kirschner wire 53 with a puncture head, and the middle part is connected and fixed as a whole by a nut 7 to form a third microtube Kirschner wire 63.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com