Medical sterilizing pot

A technology of sterilizing pots and sterilizing pots, which is applied in heating and other directions, can solve the problems that sterilizing pots are not very practical, can not meet the purpose of medical use, and the effect of sterilization is not ideal, so as to achieve convenient placement, safe structure and uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

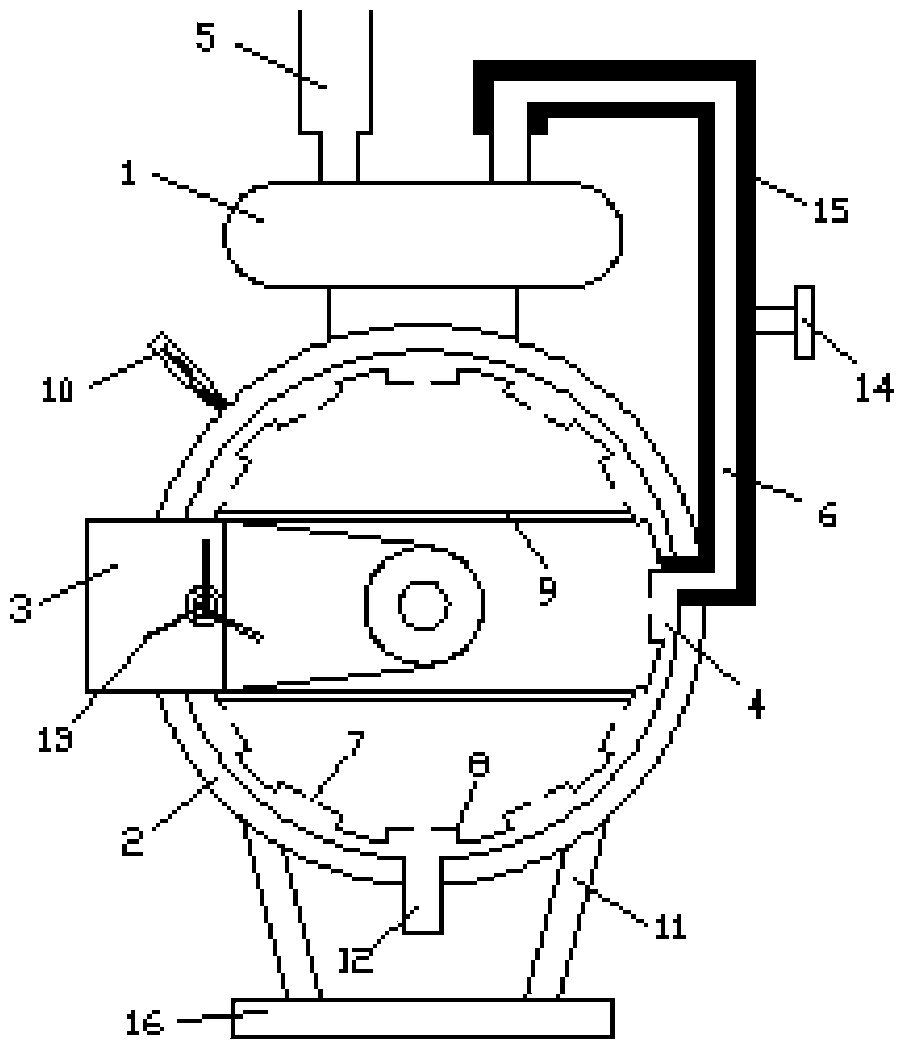

[0020] refer to figure 1 Shown: a medical sterilizer, including an electric heater 1, a sterilizer 2, a revolving door 3 and a steam pipe 4, the electric heater 1 is fixedly connected to the top of the sterilizer 2, and the two sides of the electric heater 1 Water pipes 5 and process pipes 6 are respectively provided. When in use, the revolving door 3 is opened, surgical instruments to be sterilized are placed on the separation screen 9, and the revolving handle 13 is turned to close the revolving door 14. The water vapor circulates to each bending protrusion 8, and fills the entire sterilization tank 2 evenly through the vent hole 7. After the observation thermometer 10 reaches 100°C, the sterilization process can be completed after 15 minutes. After the sterilization process is completed, open the sewage outlet 12 Drain the waste water, turn off the electric heater 1 and the valve 14, and observe that the temperature of the thermometer 41 is lower than 60°C, then open the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com