A multi-column pill counting device

A counting device and pill technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of short feeding distance, inability to count in multiple columns, insufficient filling, etc., to prolong the time of entering holes, overcome shearing and counting Inaccurate, the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

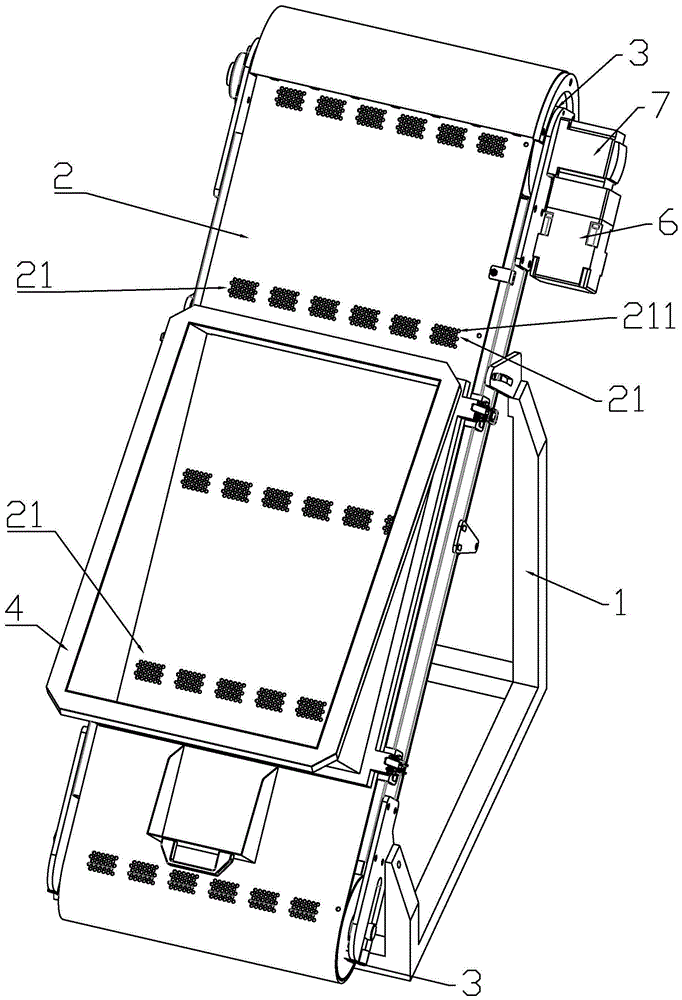

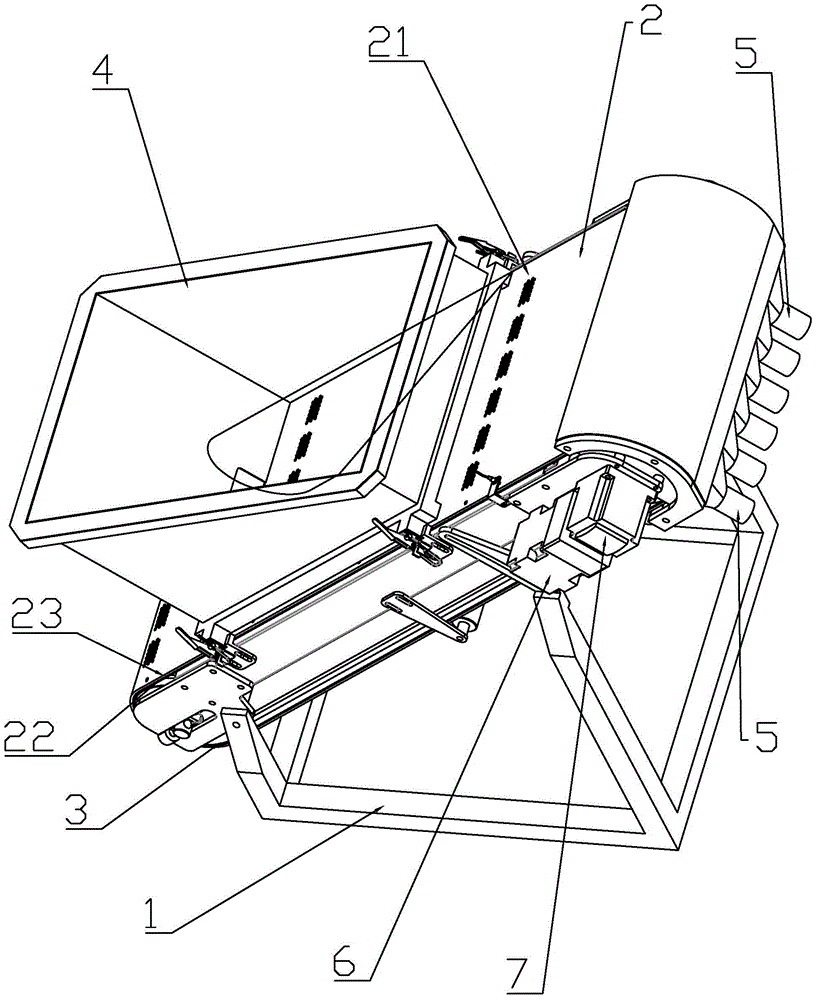

[0020] Such as figure 1 , figure 2 As shown, a multi-column pill counting device includes a frame 1, on which a belt 2 conveyed obliquely from below and a roller 3 that fixes the belt 2 and makes the belt 2 rotate with it is provided on the frame 1. Structure A roller 3 is respectively arranged above and below the frame 1, and the outer surface of the belt 2 is provided with a charge groove group 21 formed by a plurality of charge grooves 211 that can only hold a prescribed number of pills. The depth of 211 can only accommodate a pill, which is fixed to the bottom of the frame 1 and is provided with a storage hopper 4 on the upper surface of the belt 2. A large amount of pills are put into counting from here, and rollers 3 are set at the top of the frame 1. There is a receiving device 5 for collecting pills, the pills move here with the rotation of the belt 2, the charging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com