Systems and methods for improved rendering

A protein and grinding technology, applied in the field of refining, can solve the problems of expensive, large operation, less energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

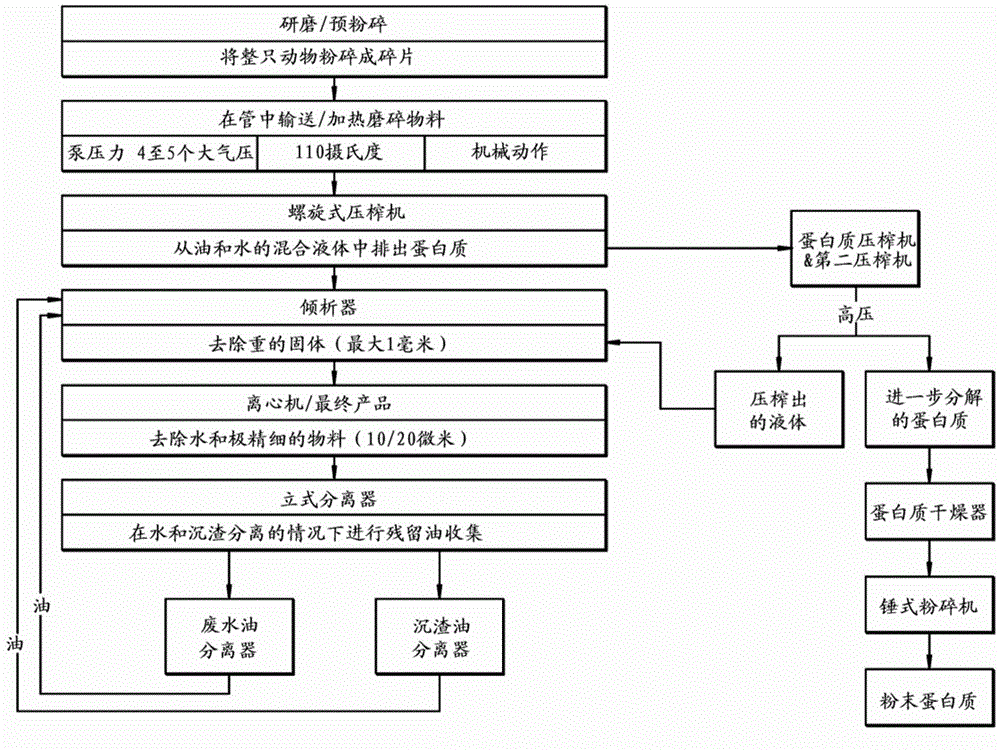

[0013] Rendering of animal products according to embodiments of the present disclosure may be accomplished through a multi-step process comprising at least a heating step using one or more steam-jacketed pipes and a pressing step. However, as will be described in more detail below, additional steps of subjecting animal products to heat and pressure may also be employed to obtain high quality oil and protein products through rendering according to embodiments of the present disclosure. Systems and methods according to embodiments of the present disclosure may also provide considerable energy savings in refining, especially compared to existing batch or continuous refining systems, due to cheaper equipment and lower operating costs, The capital expenditure (CAPEX) for such an improved refining system can be quite low.

[0014] figure 1 Methods for performing improved refinements according to embodiments of the disclosure are described. In the grinding / pre-shredding step, fats ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com