High-precision dual-channel temperature measuring circuit for spacecraft ontrack leakage detection

A temperature measurement circuit and dual-channel technology, applied in the field of temperature measurement, can solve the problems affecting the temperature measurement accuracy and difficulty in meeting the accuracy requirements, so as to eliminate nonlinearity, ensure consistency and independence, and realize dual-channel high-precision temperature measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is a specific implementation manner of the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode below. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

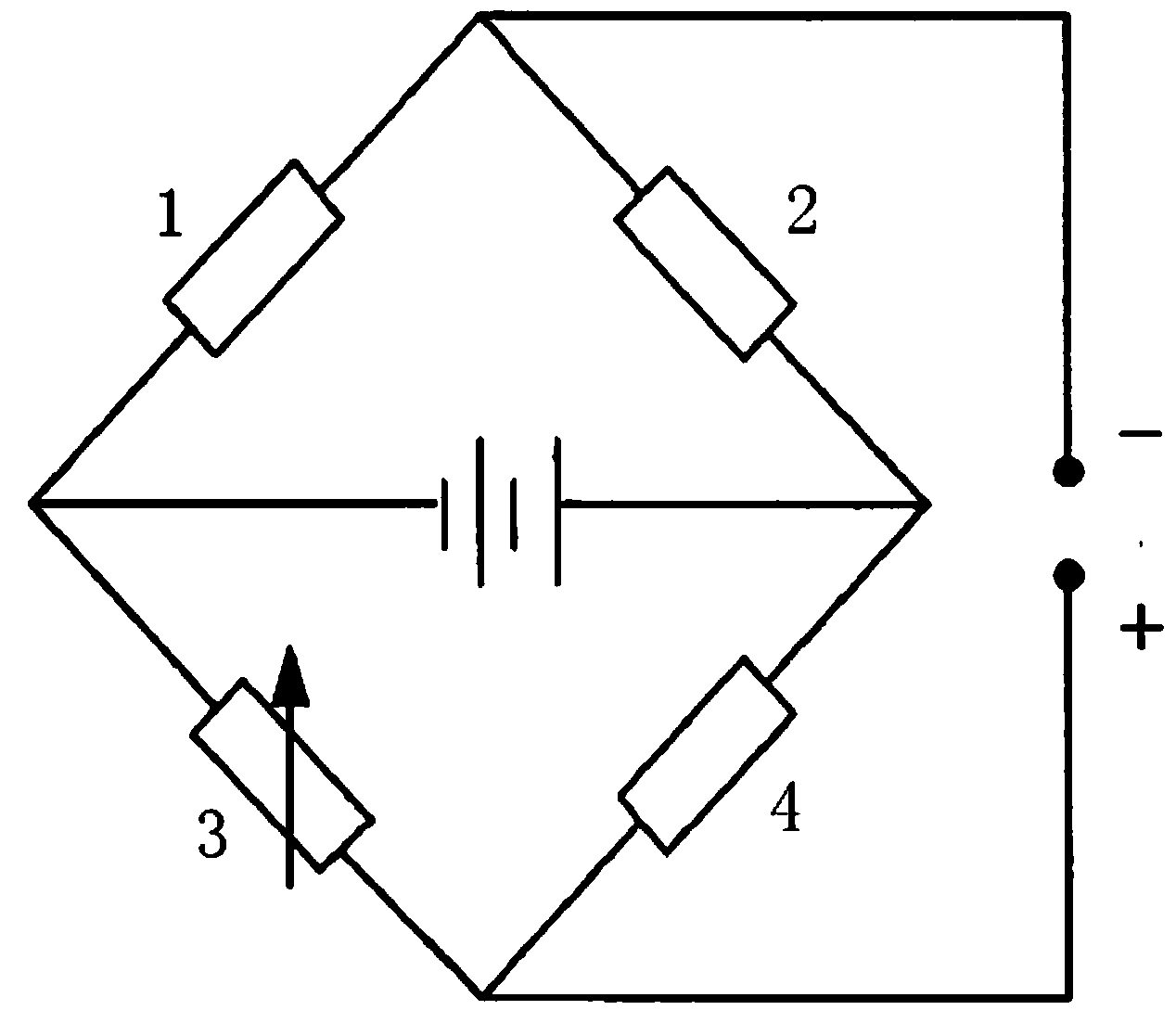

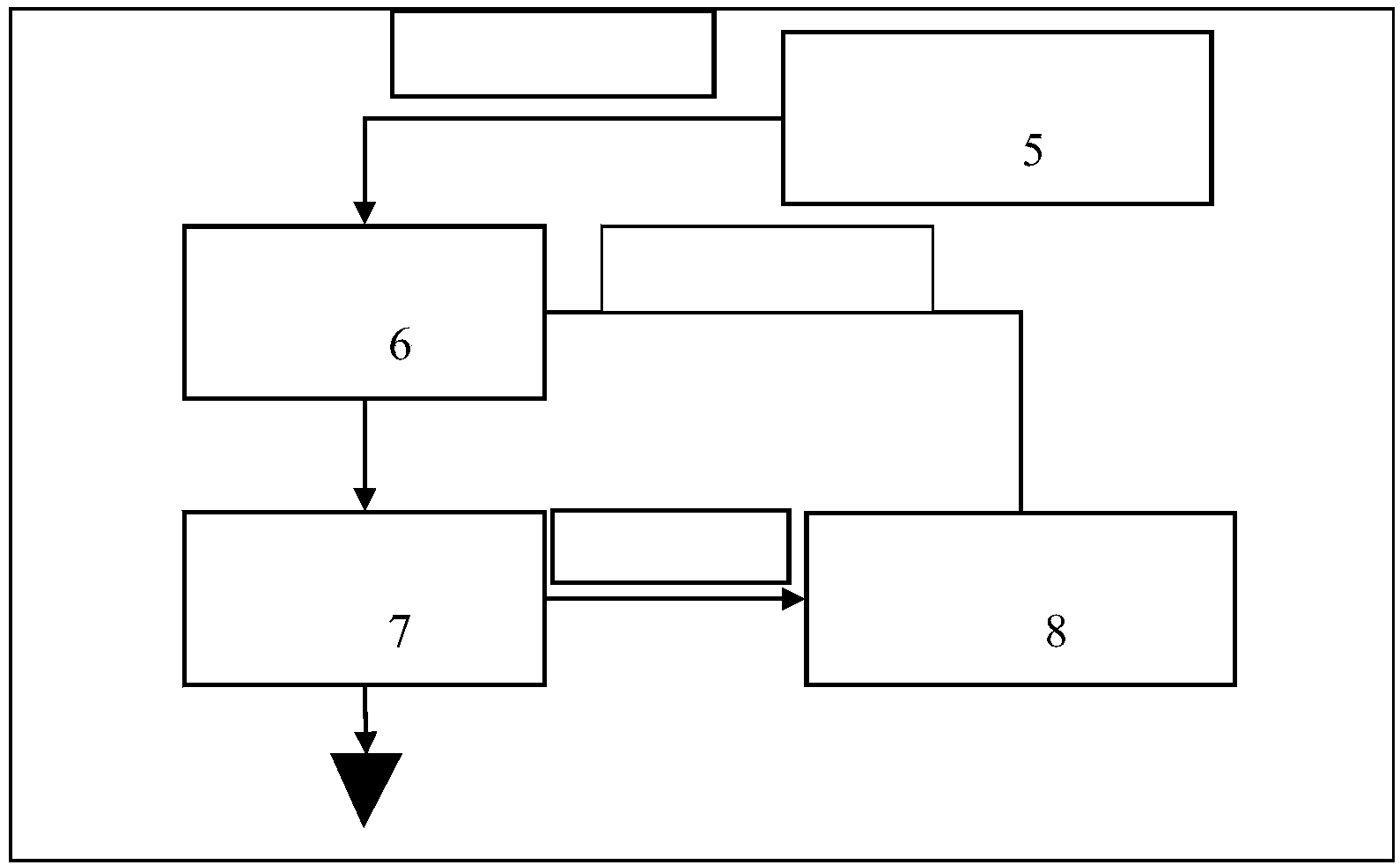

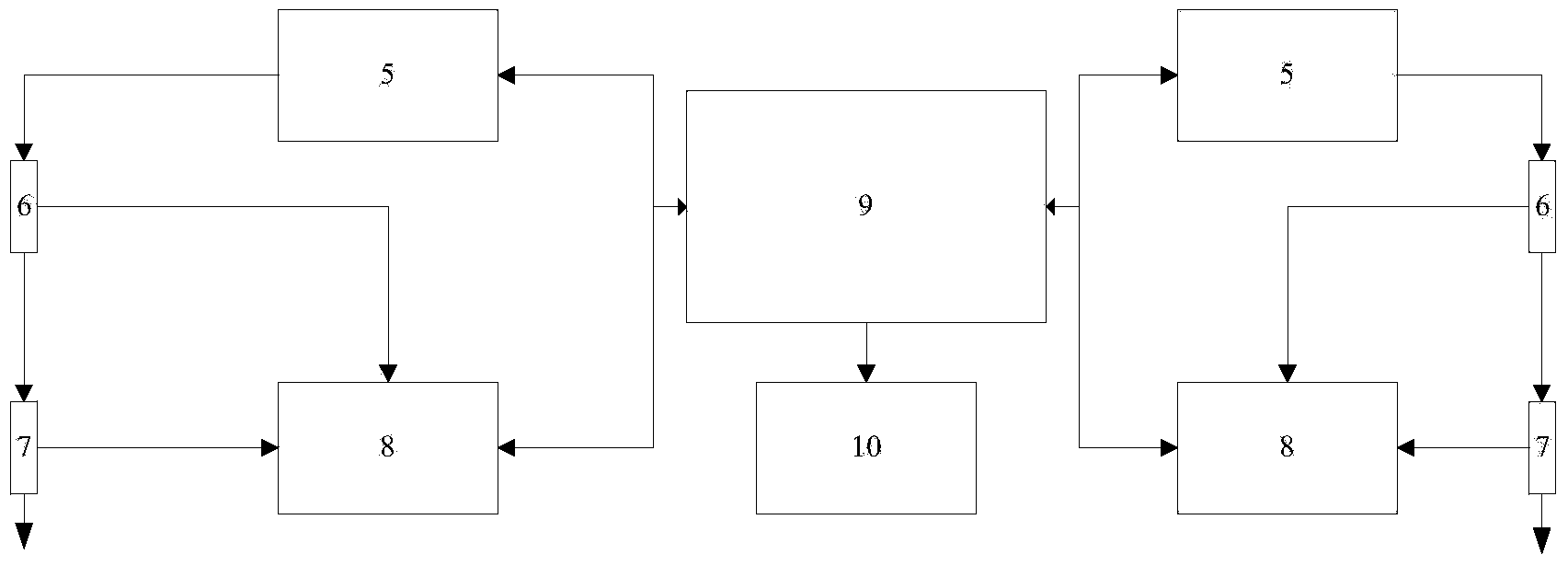

[0022] refer to figure 2 , figure 2 A schematic diagram of a certain temperature measuring circuit in the dual temperature measuring circuit of the present invention is shown. Wherein, the temperature measurement circuit includes a micro-current constant current source 5 such as an ADS1247 chip, a high-precision standard resistor 6, a four-wire thermistor sensor 7 with a shielded ground wire, and a 24-bit AD sampling component 8, such as an ADS1255 chip; , the microcurrent constant current source 5 supplies power to the high-precision standard resistor 6 and the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com