Simulation experiment device for scaling of water heater

A technology for simulating experimental devices and water heaters, which can be applied to measuring devices, instruments, scientific instruments, etc., and can solve the problems of lack of simulating experimental devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

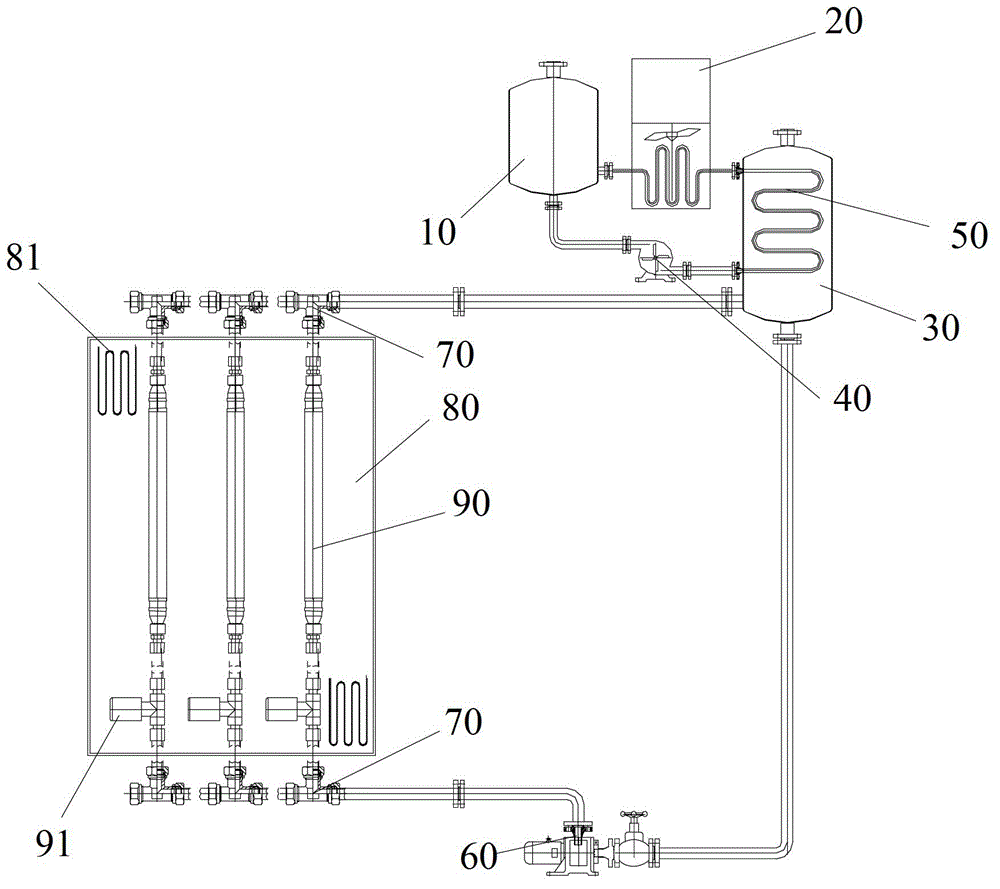

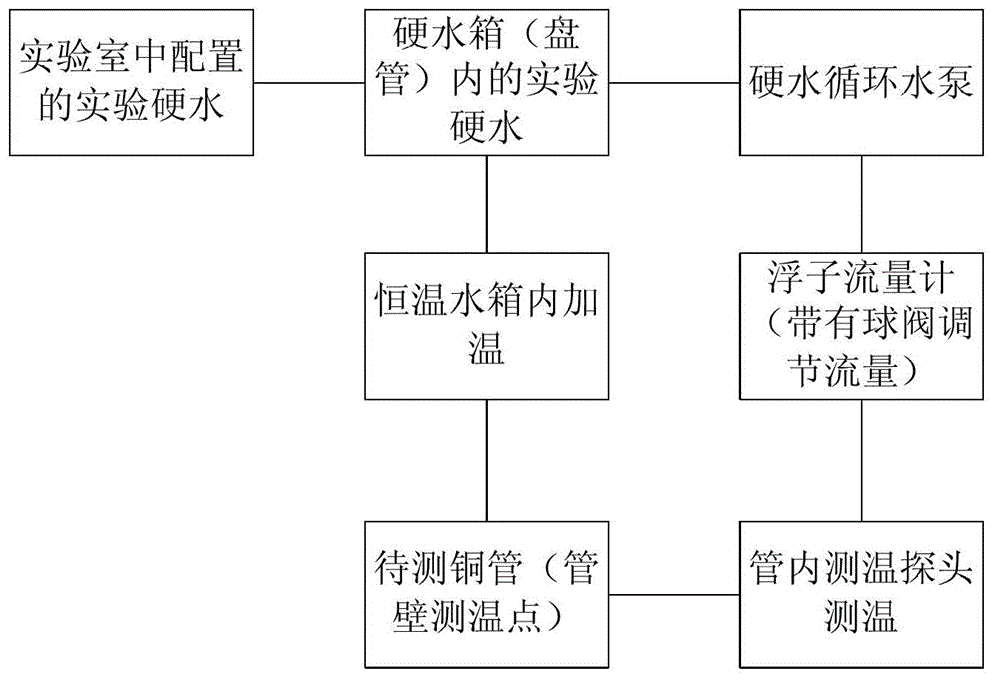

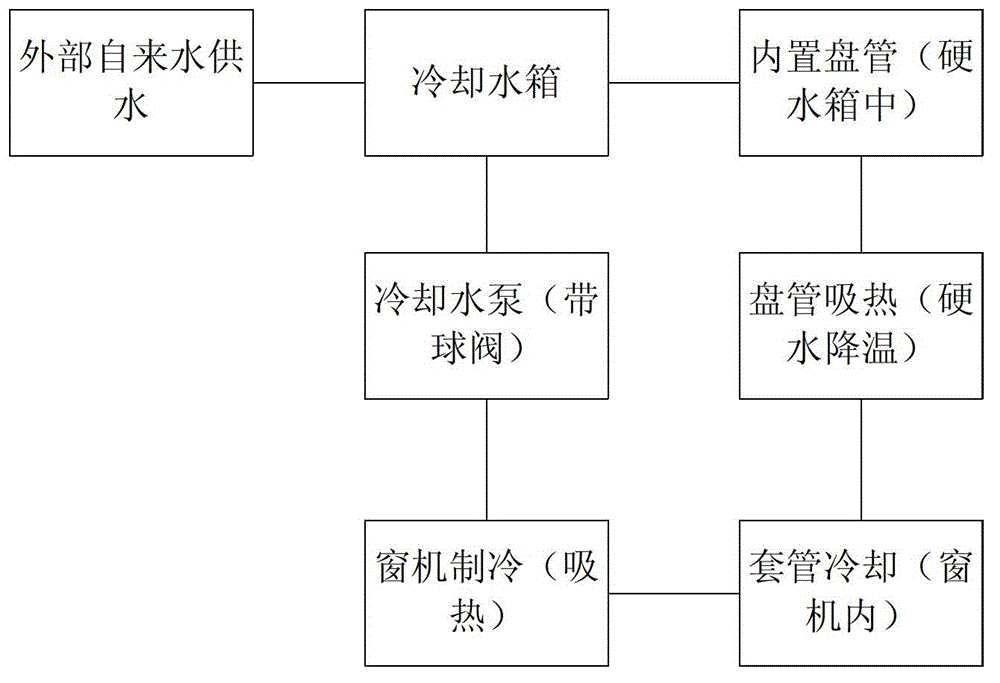

[0022] see figure 1 As shown, in the hot water machine fouling simulation experiment device of the present invention, the heat exchange tube 90 to be tested is placed in the constant temperature water tank 80 heated by the heating tube 81, and the configured hard water flows from the hard water tank 30 through the circulating water pump 60. After the temperature measuring probe 70 , the flow meter 91 , the heat exchange tube 90 , it is finally returned to the hard water tank 30 . In order to control the temperature rise of the hard water tank 30 due to the heat exchange cycle, a built-in coil pipe 50 is designed in the hard water tank 30, and a casing is set on the cooling pipeline, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com