A method and device for testing the whole pos machine

A technology for testing POS machines and complete machines, which is applied to measuring devices, measuring electricity, and measuring electrical variables. The effect of dysfunctional risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

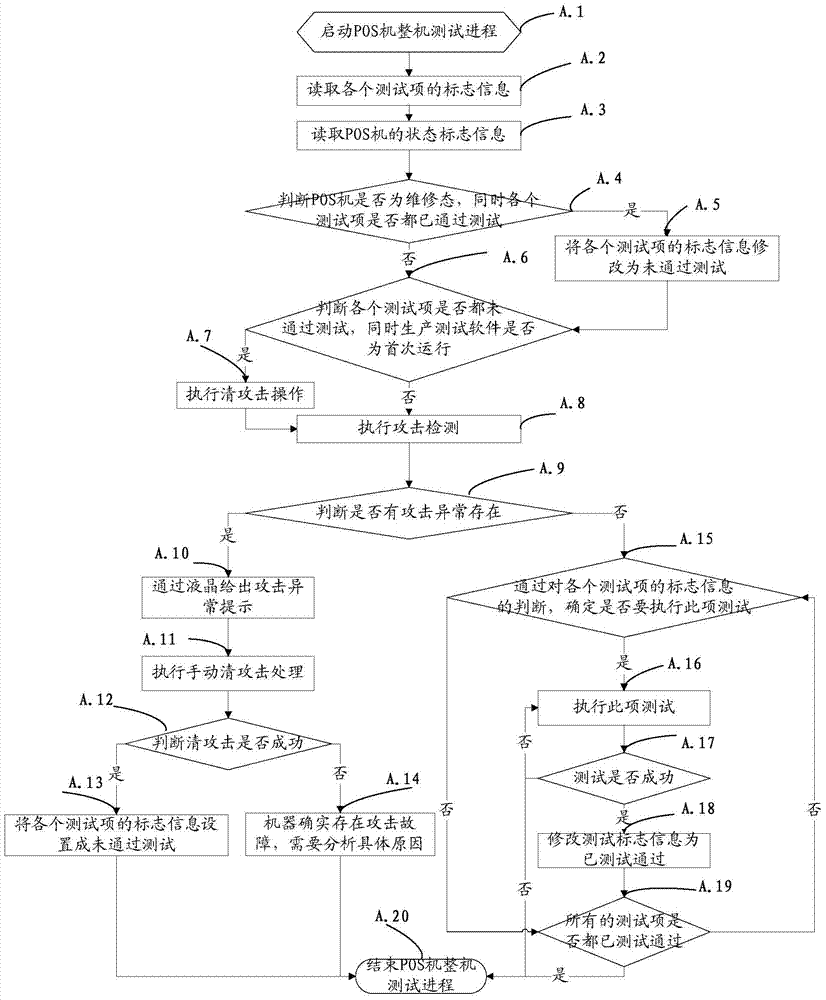

[0097] Please refer to figure 2 , Embodiment 1 of the present invention is:

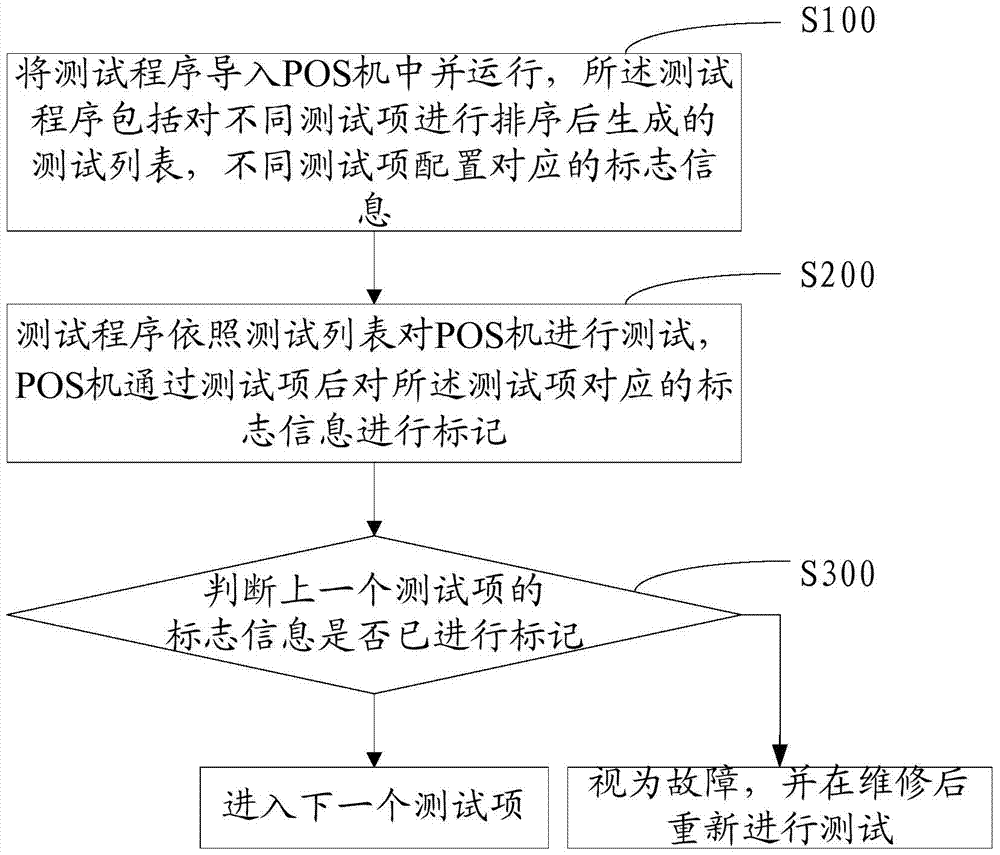

[0098] A method for testing the leak-proof design of the whole POS machine is as follows:

[0099] A.1: After starting up, you can enter the test process of the whole machine through the pre-set button menu selection;

[0100] A.2: After entering the whole machine test, the program will first read the flag information of each test item, and store the read flag information in a variable cache;

[0101] A.3: Next, the program will read the status information of the POS machine to confirm whether the machine has passed the final inspection operation; A.4: Through the comprehensive judgment of the flag information of each test item and the status information of the POS machine, confirm Whether the machine has an abnormal attack after the final inspection is successful;

[0102] A.5: If an attack exception occurs after the final inspection, the attack operation will be automatically cleared during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com