Fiber grating sensor multifunctional testing device and method

A grating sensor, multi-functional testing technology, applied in the direction of measuring devices, instruments, etc., can solve the problems that the temperature of the fiber grating sensor cannot be quantitatively changed, there is no popular application, and the fiber grating sensor cannot be applied, etc., to achieve simple structure, convenient operation, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

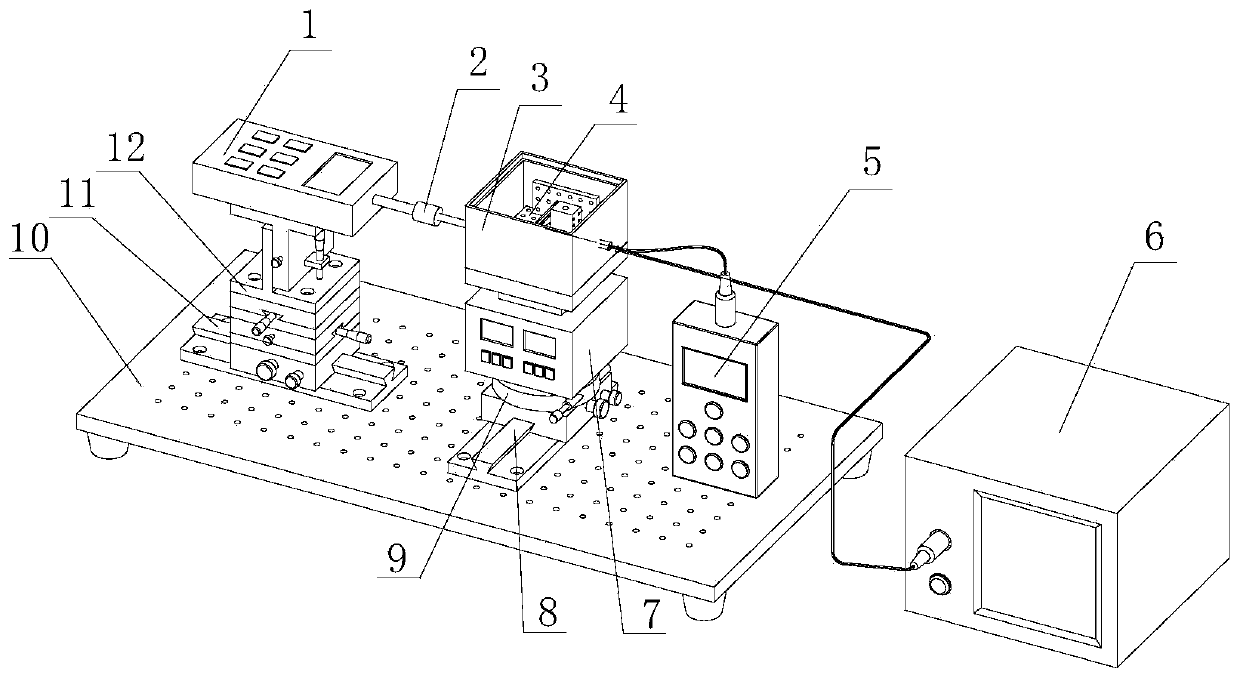

[0036] exist figure 1 Among them, the fiber Bragg grating sensor multifunctional testing device of the present embodiment is composed of a push-pull force meter 1, a sensor connector 2, a heat preservation cover 3, a sensor holder 4, a temperature measuring instrument 5, a fiber grating demodulation device 6, a constant temperature heater 7, The second rack and pinion translation platform 8, the rotary lifting platform 9, the optical platform 10, the first rack and pinion translation platform 11, and the three-dimensional combination translation platform 12 are connected to form.

[0037]On the left side of the optical table 10, a first rack-and-pinion translation stage 11 is installed, and a second rack-and-pinion translation stage 8 is installed on the right side. The first rack-and-pinion translation stage 11 is used for left-right adjustment, and the second rack-and-pinion translation stage 8 is used for front and rear adjustment, and the three-dimensional combined transla...

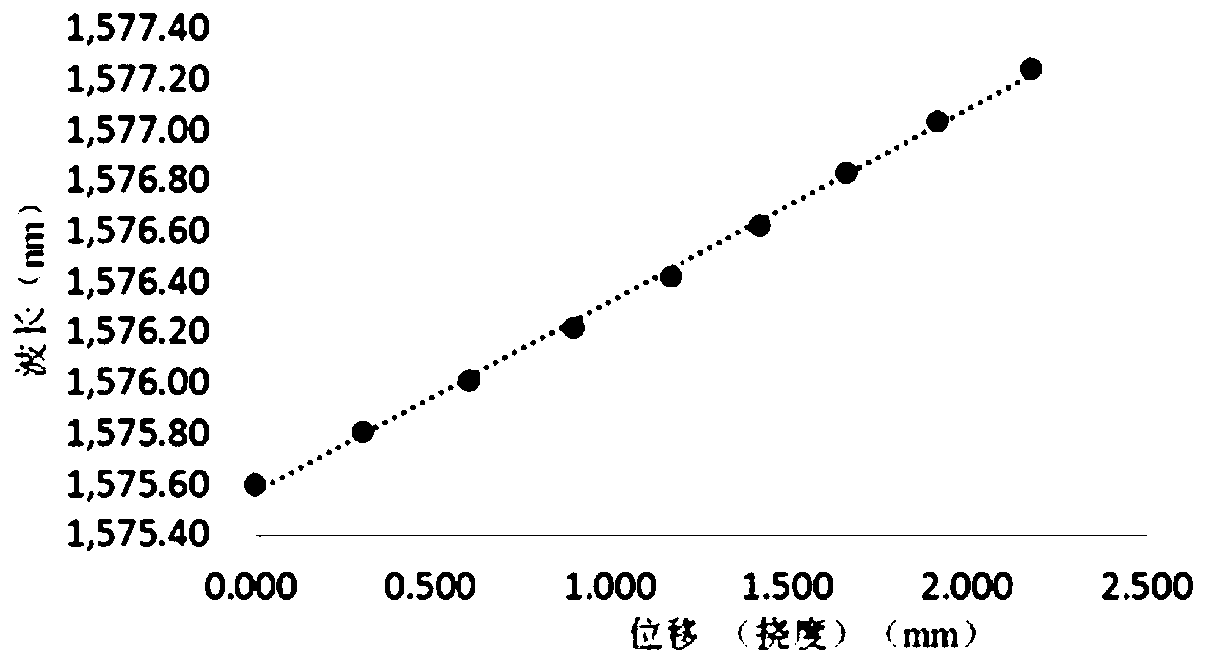

Embodiment 2

[0049] In this embodiment, the test device of Embodiment 1 is used to carry out the displacement sensing test on the optical fiber grating sensor with the cantilever structure of equal strength beryllium copper as the cantilever material. The specific test method includes the following steps:

[0050] S1. Install the fiber grating sensor to be tested and the sensor connector 2

[0051] a. Fix the fiber grating sensor to be tested on the sensor holder 4, and cover the heat preservation cover 3;

[0052] b. Adjust the vertical displacement screw micrometer sleeve of the three-dimensional combined translation stage 12, so that the sensor connector 2 located at the front end of the push-pull force meter 1 is at the same height as the free end stress point of the cantilever beam of the fiber grating sensor to be tested, and adjust the first gear The rack and pinion translation stage 11 and the second rack and pinion translation stage 8 make the sensor connector 2 roughly aligned wi...

Embodiment 3

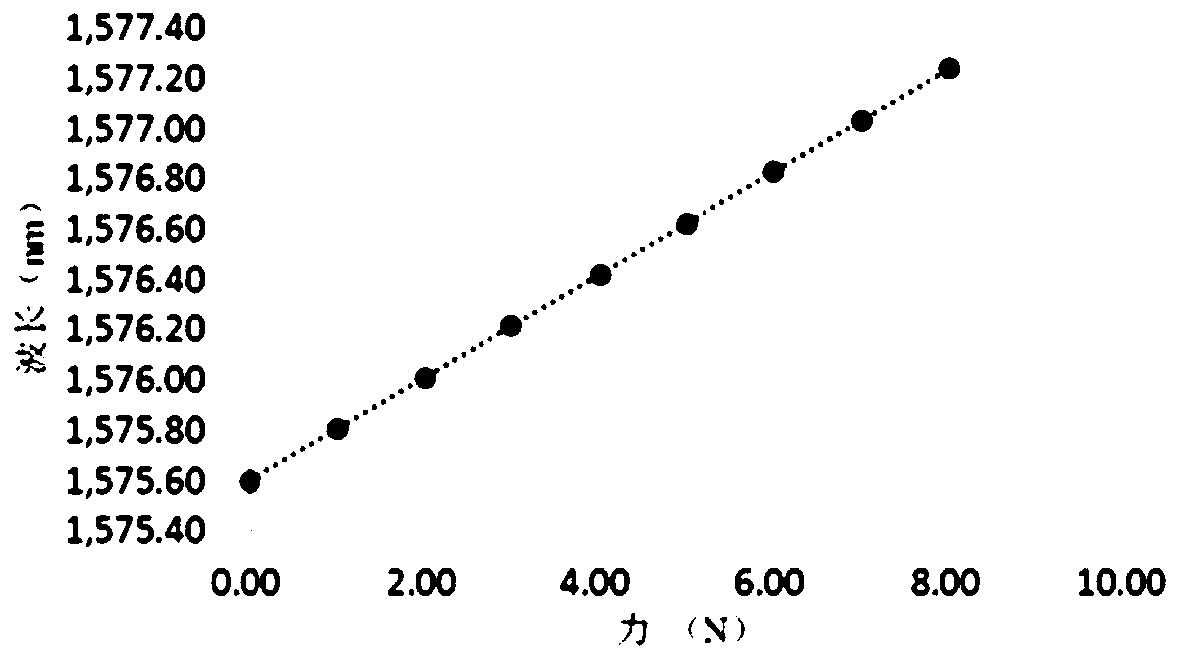

[0060] In this embodiment, the test device of Embodiment 1 is used to carry out the stress sensing test on the fiber grating sensor with the cantilever structure of equal strength beryllium copper as the cantilever material. The specific test method includes the following steps:

[0061] S1. Install the fiber grating sensor to be tested and the sensor connector 2

[0062] a. Fix the fiber grating sensor to be tested on the sensor holder 4, and cover the heat preservation cover 3;

[0063] b. Adjust the vertical displacement screw micrometer sleeve of the three-dimensional combined translation stage 12, so that the sensor connector 2 located at the front end of the push-pull force meter 1 is at the same height as the free end stress point of the cantilever beam of the fiber grating sensor to be tested, and adjust the first gear The rack and pinion translation stage 11 and the second rack and pinion translation stage 8 make the sensor connector 2 roughly aligned with the force p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com