clamping equipment

A clamping device and clamping technology, applied in the field of machine components, which can solve the problems affecting the repeatability of measurement and achieve the effect of high balance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

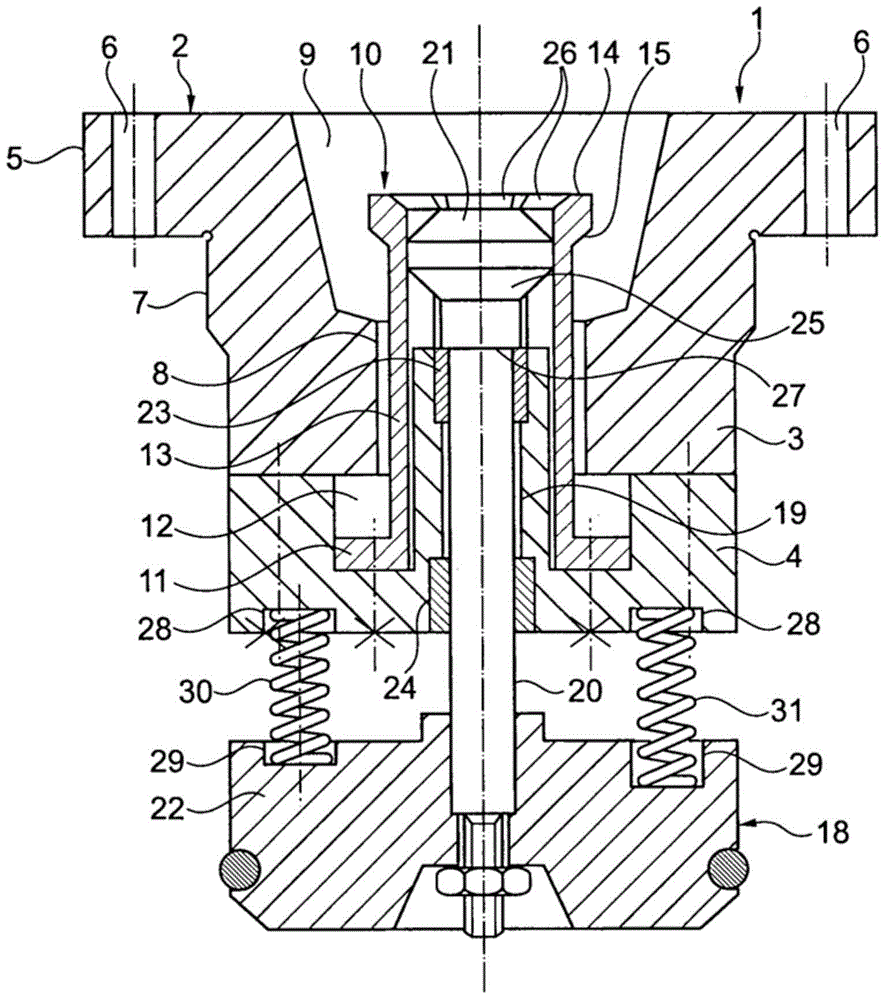

[0018] The shown clamping device 1 is positively inserted into the open end of the hollow spindle of the balancing machine for this purpose. The clamping device 1 has a receiving unit 2 consisting of two parts connected to each other by a screw connection, a receiving part 3 and a bearing part 4 . The flange 5 with fastening bores 6 on the receiving part 3 is used to fasten the receiving unit 2 on the end face of the hollow spindle. For precise centering relative to the hollow spindle, the receiving part 3 is provided with a centering surface 7 on its outer side. A through-hole 8 extends axially through the receptacle 3 , which leads to a central receptacle opening 9 which is designed to receive a standardized hollow bevel-cone coupling shaft of a tool. It is of course also possible to form the receptacle 3 which also has a differently designed receptacle opening for receiving a differently shaped clutch shaft.

[0019] In the through-opening 8 there is a clamping jaw 10 , w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com