Method for balancing component

A technology for balancing components and components, applied in the field of motor components, motors, devices, and rotors of motors, can solve problems such as high requirements, achieve high stability and improve the effect of balancing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

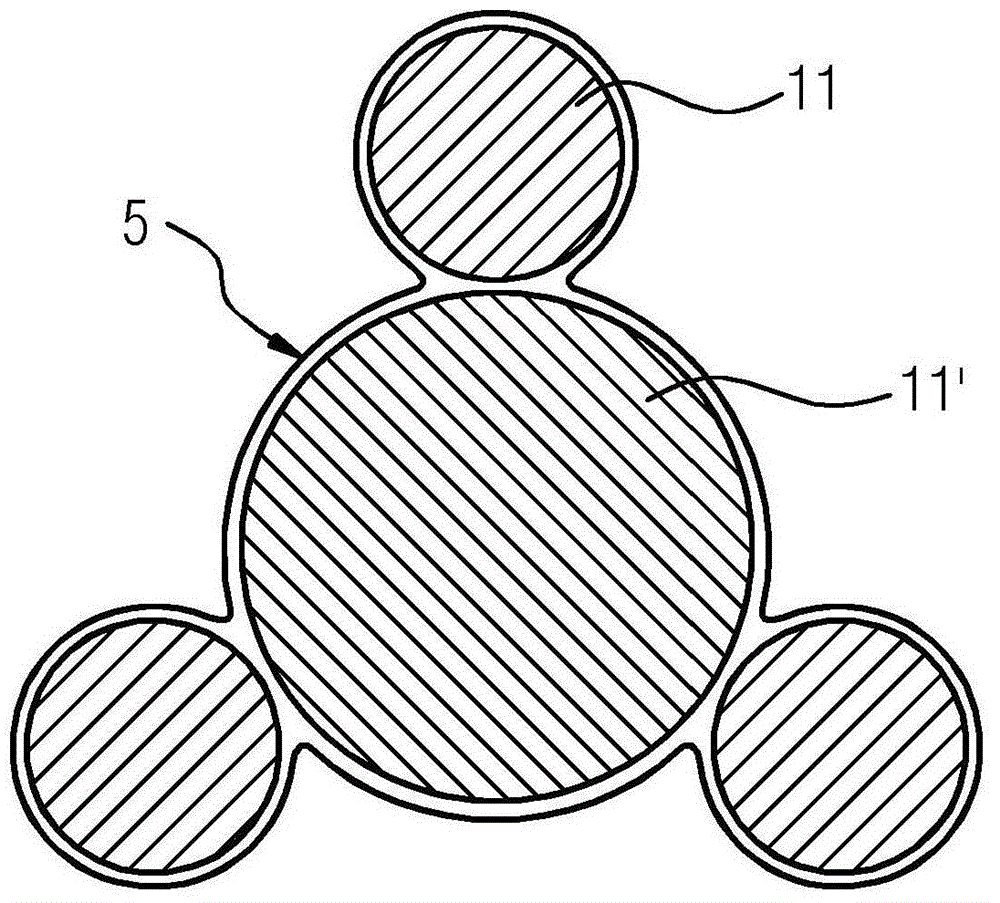

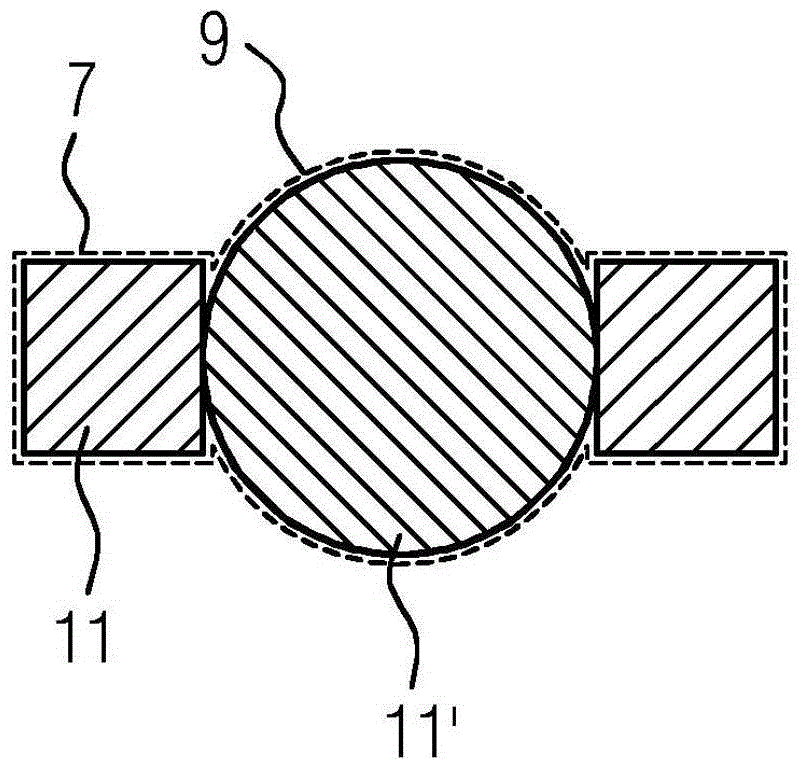

[0023] figure 1 A top sectional view of the assembly 1 is shown. In assembly 1 there is a cross-section of the composite lamination 3 of the rotor of the electric machine. The combined laminations have, for example, gaps 4 for weight reduction, and openings 5, 7, 9. Such as figure 2 As shown again in , the opening 5 consists of circular openings 7 , 9 . The circular openings 7 , 9 serve to accommodate corresponding cylindrically shaped pins 11 , 11 ′. The shown arrangement proves to be space-saving, in which the opening 5 for receiving the cylindrically shaped pins 11 , 11 ′ is located between the two gaps 4 . The arrangement shown thus facilitates reducing the weight, the inertia factor and the space requirement of the composite lamination 3 . In order to balance the assembly, the assembly is put into rotation and the centrifugal moment generated at this time is measured. Next, the weight of the pin 11 , 11 ′ for each opening 7 , 9 is calculated and the corresponding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com