Refrigerant compressor and heat pump device

A refrigerant and compressor technology, applied in compressors, refrigerators, compressors, etc., can solve the problem of insufficient return of lubricating oil, and achieve the effect of reducing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

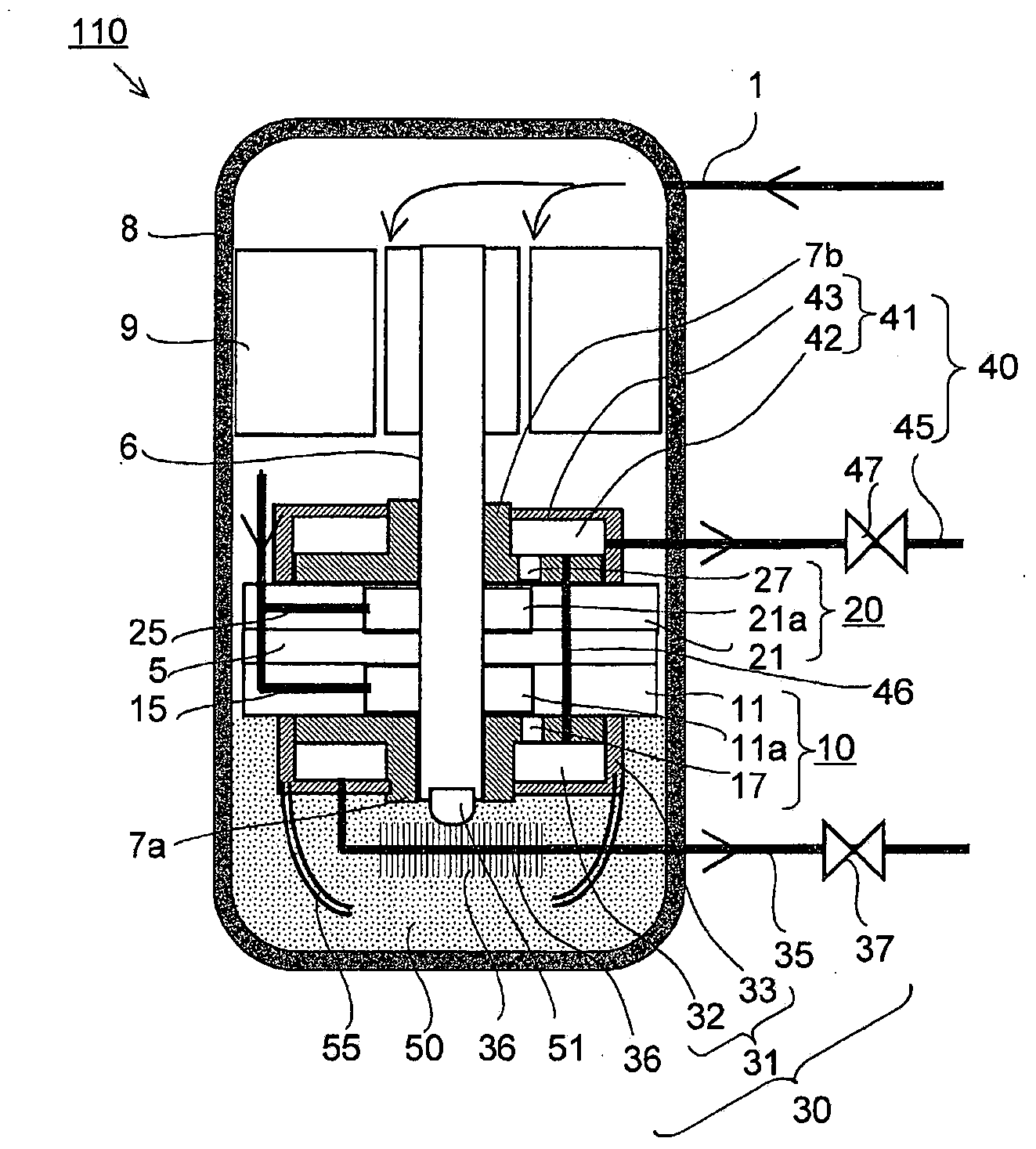

[0067] figure 1 It is a longitudinal sectional view schematically illustrating the refrigerant compressor according to Embodiment 1 of the present invention. In addition, each part is a part drawn schematically, and this invention is not limited to the form shown in figure.

[0068] (Low-pressure shell type 2-cylinder compressor)

[0069] exist figure 1 Among them, the refrigerant compressor (hereinafter referred to as "low-pressure shell-type 2-cylinder compressor" or "refrigerant compressor") 110 has an airtight container 8, an electric motor 9 installed in the airtight container 8, and a drive shaft driven by the electric motor 9. 6. The short-axis side bearing 7a and the long-axis side bearing 7b supporting both ends of the drive shaft 6, the first (lower side) compression mechanism 10 composed of the first (lower side) cylinder 11, and the second (lower side) compression mechanism 10 formed by the second (lower side) The second (upper) compression mechanism 20 constitu...

Embodiment approach 2

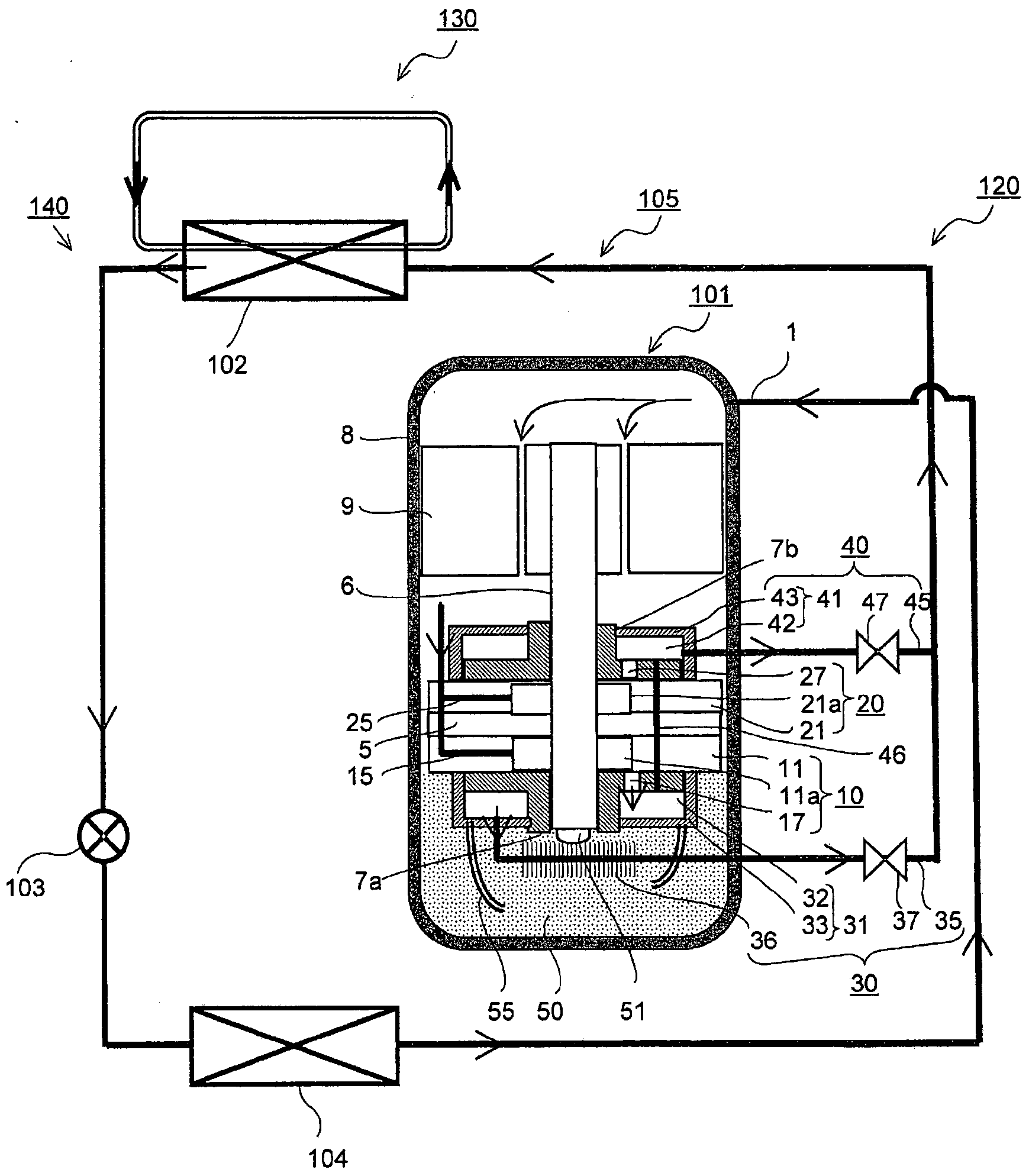

[0084] figure 2 It is a configuration diagram schematically illustrating a partial longitudinal section of a heat pump device according to Embodiment 2 of the present invention. In addition, the same parts as those in Embodiment 1 are assigned the same reference numerals, and a part of description is omitted. In addition, each part is a part drawn schematically, and this invention is not limited to the form shown in figure.

[0085] (heat pump hot water supply)

[0086] exist figure 2 Among them, a heat pump device (hereinafter referred to as “heat pump water heater”) 140 includes a main refrigerant circuit 120 and a utilization fluid circuit 130 . The main refrigerant circuit 120 implements a refrigeration cycle through a refrigerant compressor 110 , a radiator 102 , an expansion valve 103 , an evaporator 104 , and refrigerant piping 105 sequentially connecting them to circulate the refrigerant.

[0087]Here, the refrigerant compressor 110 is the low-pressure shell type...

Embodiment approach 3

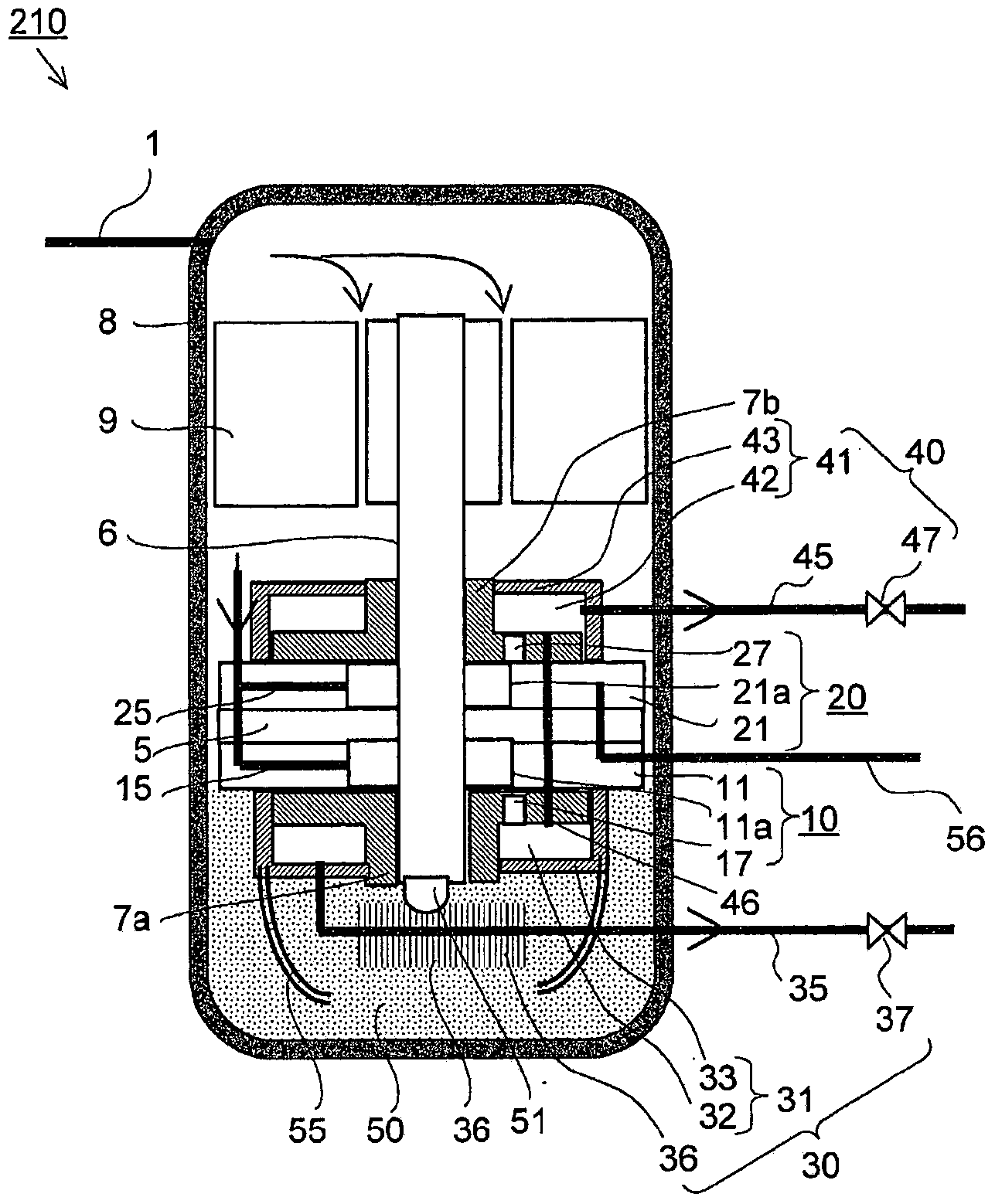

[0095] image 3 It is a longitudinal section schematically illustrating the refrigerant compressor according to Embodiment 3 of the present invention. In addition, the same parts as those in Embodiment 1 are assigned the same reference numerals, and a part of description is omitted. In addition, each part is a part drawn schematically, and this invention is not limited to the form shown in figure.

[0096] (Low-pressure shell type 2-cylinder compressor)

[0097] exist image 3 Among them, a refrigerant compressor (hereinafter referred to as “low pressure shell type 2-cylinder compressor”) 210 is provided with an oil return circuit 56 . The oil return circuit 56 is used to transfer the refrigerant flowing out from one or both of the first (lower) discharge flow path 35 and the second (upper side) discharge flow path 45 in a refrigerant circuit (not shown). After the oil is separated, the separated oil is returned to the first (lower) compression mechanism 10 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com