Combined type household plant factory

A combined, home-based technology, applied in the fields of botanical equipment and methods, soilless cultivation, cultivation, etc., can solve the problems of cumbersome maintenance and the inability of ordinary home plant factories to adapt to various needs, and achieve the effect of reducing light pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

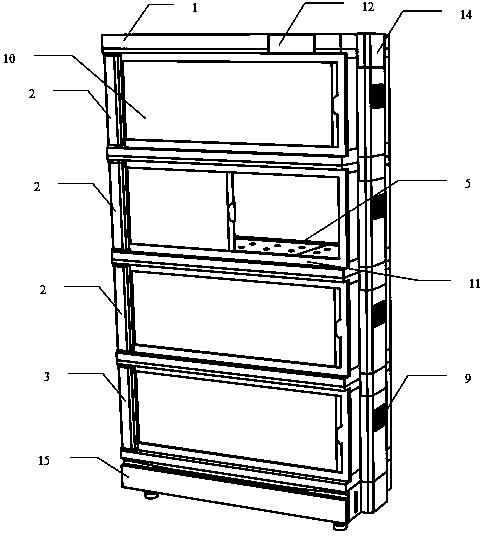

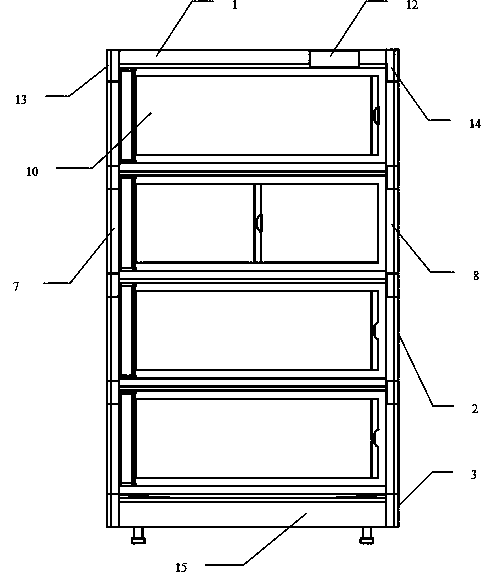

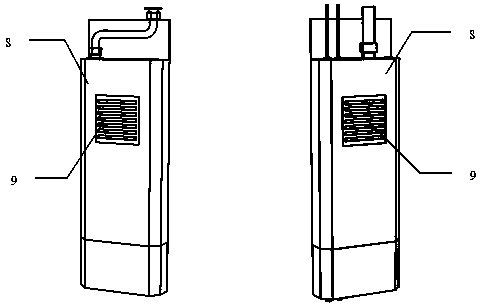

[0019] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the present embodiment is a combined family plant factory, comprising a top cladding layer 1, three combined layer cabinets 2 and a bottom cabinet 3; the top of each combined layer cabinet 2 is provided with an LED light source, with The planting board 4 with twenty-four planting tanks 6 is laid in the planting water tank 5, the left side is provided with the waterway module unit 7 and the ventilation hole 9 that are plugged in with each other, and the right side is provided with the circuit module unit 8 and the ventilation hole that are matched with each other 9. The front end is equipped with a horizontal pull type rolling shutter cabinet door 10 and a matching cabinet door sliding frame 11; the front of the top cladding layer 1 is provided with a control panel 12, a waterway closing module 13 is provided on the left side, and a circuit closing module is provided on the right side Module 14; the bottom cab...

specific Embodiment 2

[0021] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the present embodiment is a combined family plant factory, comprising a top cladding layer 1, three combined layer cabinets 2 and a bottom cabinet 3; the top of each combined layer cabinet 2 is provided with an LED light source, with The planting board 4 with twenty-four planting tanks 6 is laid in the planting water tank 5, the left side is provided with the waterway module unit 7 and the ventilation hole 9 that are plugged in with each other, and the right side is provided with the circuit module unit 8 and the ventilation hole that are matched with each other 9. The front end is equipped with a horizontal pull-type rolling shutter door 10 and a matching door sliding groove 11; the front of the top cladding layer 1 is provided with a control panel 12, a waterway closing module 13 is provided on the left side, and a circuit closing module is provided on the right side. Module 14; the bottom cabinet 3 is prov...

specific Embodiment 3

[0024] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present embodiment is a combined family plant factory, comprising a top cladding layer 1, three combined layer cabinets 2 and a bottom cabinet 3; the top of each combined layer cabinet 2 is provided with an LED light source, with The planting board 4 with twenty-four planting tanks 6 is laid in the planting water tank 5, the left side is provided with the waterway module unit 7 and the ventilation hole 9 that are plugged in with each other, and the right side is provided with the circuit module unit 8 and the ventilation hole that are matched with each other 9. The front end is equipped with a horizontal pull-type rolling shutter door 10 and a matching door sliding groove 11; the front of the top cladding layer 1 is provided with a control panel 12, a waterway closing module 13 is provided on the left side, and a circuit closing module is provided on the right side. Module 14; the bottom cabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com