A customized lingual orthodontic bracket and its manufacturing method

A technology of orthodontic brackets and brackets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

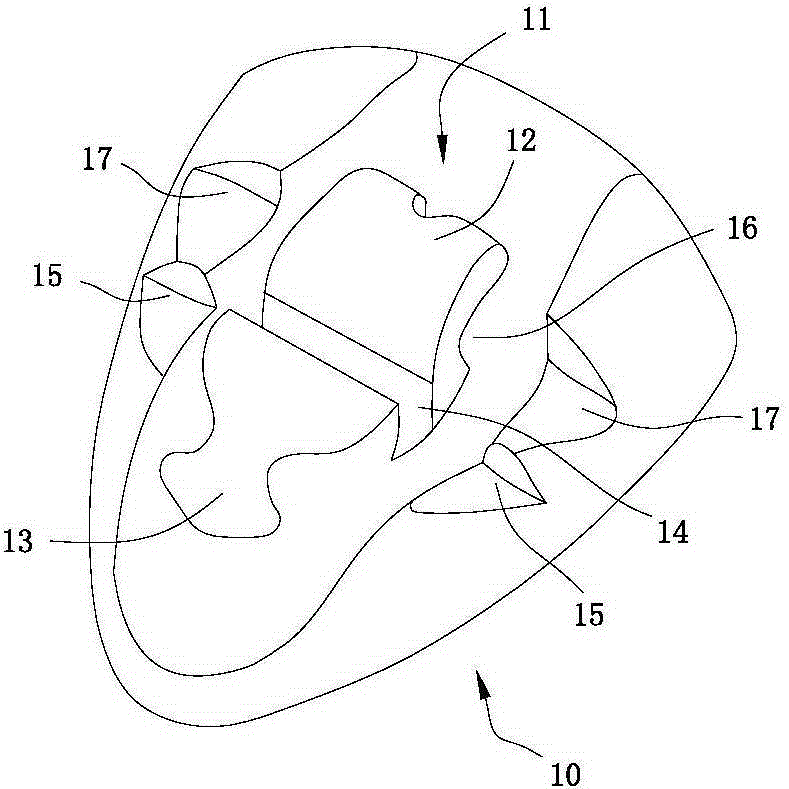

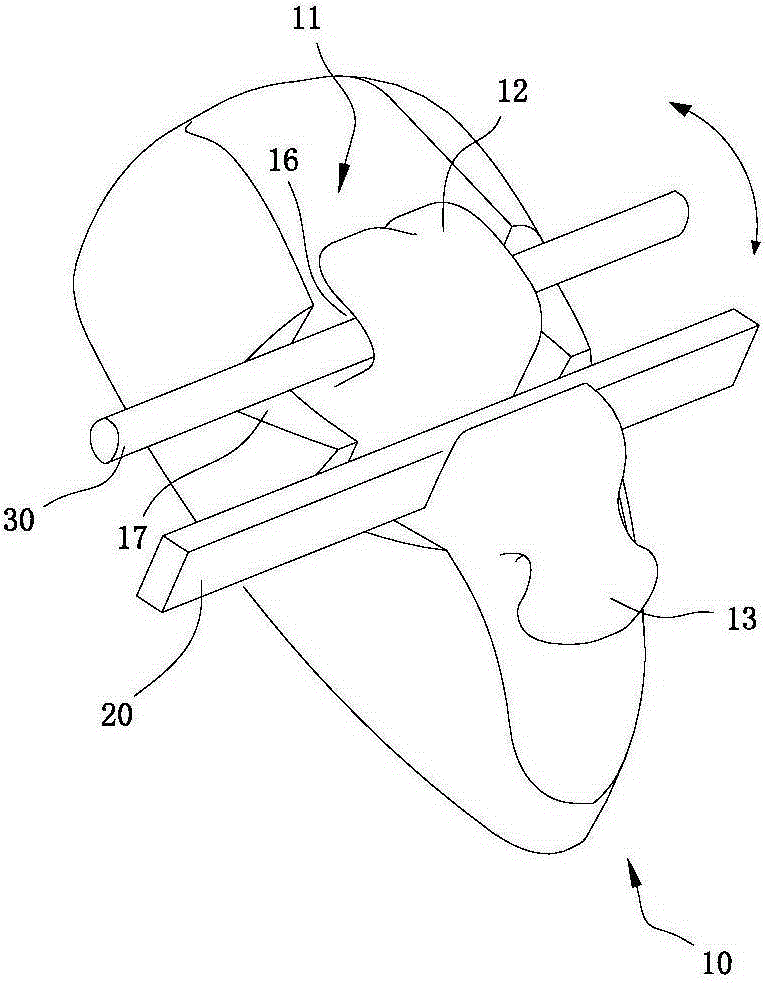

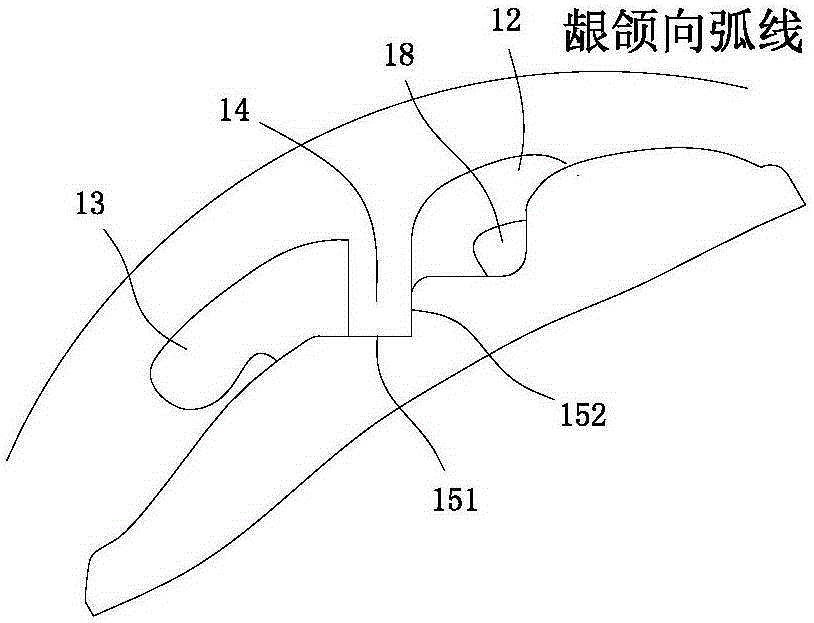

[0034] refer to Figures 1 to 6 , a customized lingual orthodontic bracket according to the present invention, comprising a spherical crowned bracket body 10 defined jointly by the tooth surface and the lingual surface, the tooth surface of the bracket body 10 coincides with the lingual tooth surface, The lingual surface of the bracket body 10 is a circular arc surface, and the middle area of the lingual surface of the bracket body 10 is inwardly recessed to form a depression 11. The bracket body 10 is located in the depression 11 and is respectively provided with gingiva maxillary extensions. The upper wing 12 and the lower wing 13 of the upper wing 12 and the lower wing 13 are provided with a groove 14 in the mesial and far direction between the upper wing 12 and the lower wing 13. The lingual surface of the bracket body 10 is in contact with the outer surfaces of the upper wing 12 and the lower wing 13. The circular arc profile is still maintained.

[0035] Wherein, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com