An ultra-high pressure rotary sealed water jet cleaner

A rotary seal and ultra-high pressure technology, applied in the field of cleaners, can solve the problems of unsuitable lubricity, low viscosity, and low cleaning efficiency, and achieve the effects of good rust removal effect, easy use, and simple structure by water jets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

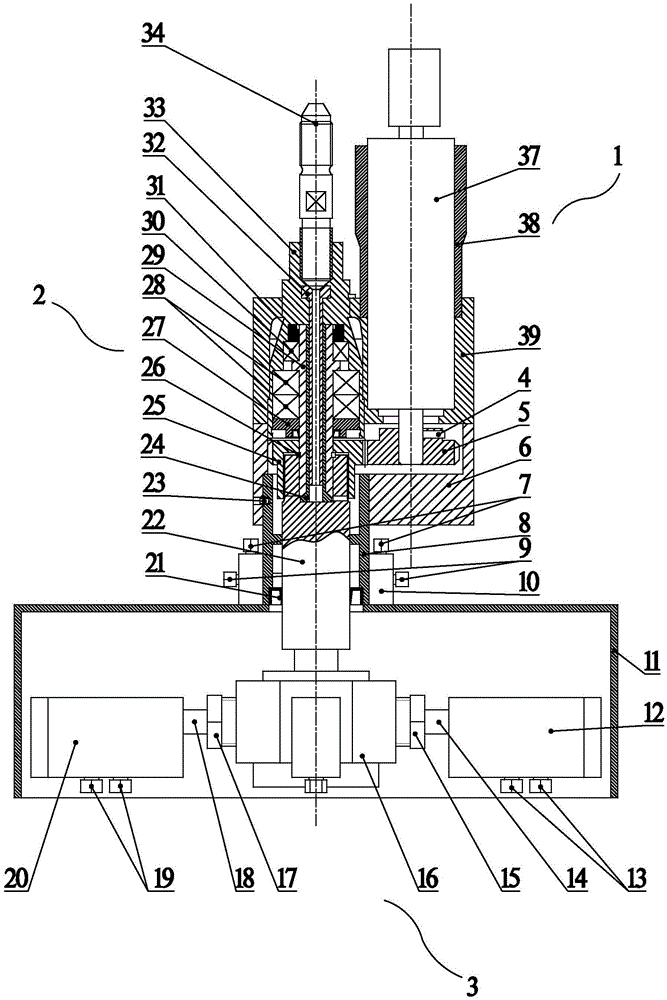

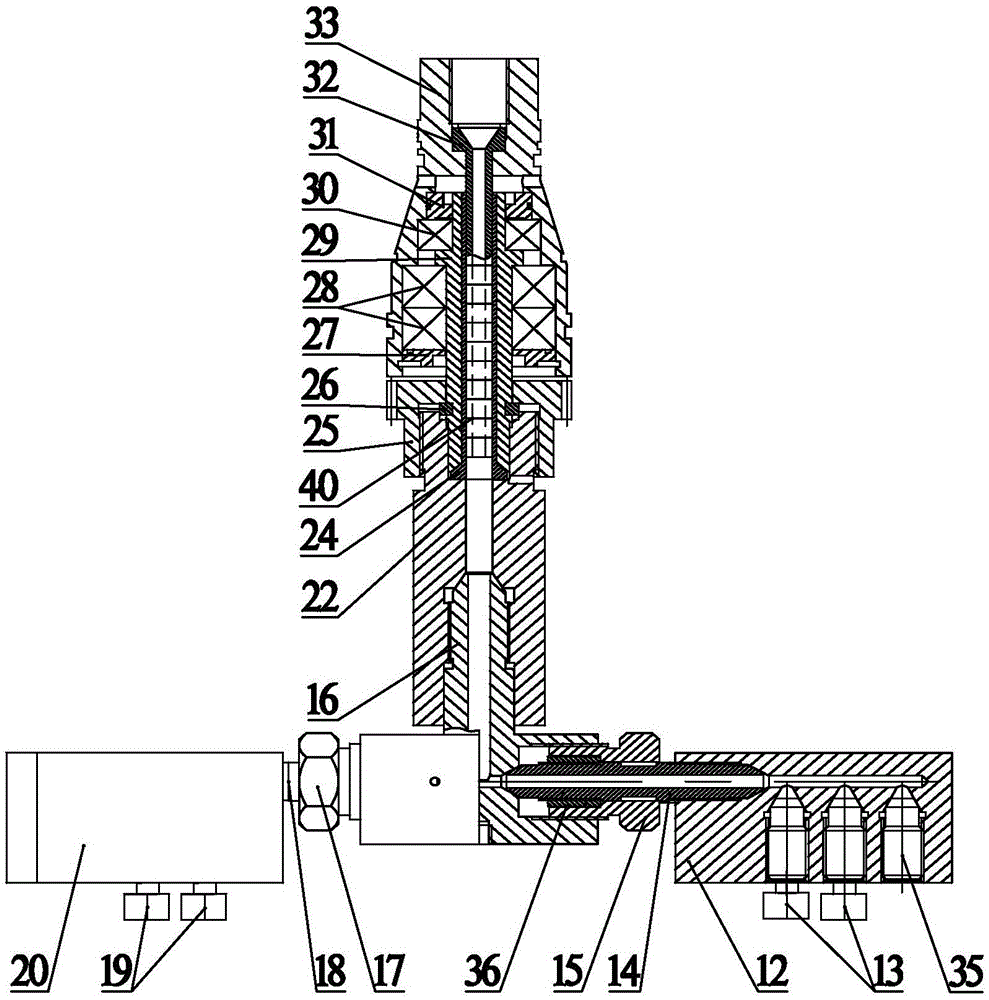

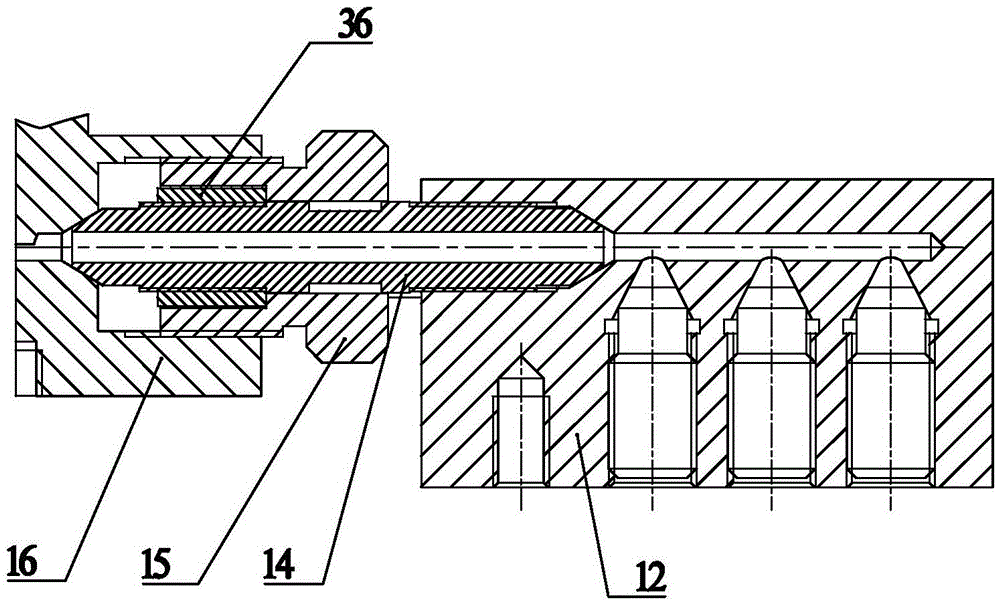

[0024] Such as figure 1 and figure 2 As shown, an ultra-high pressure rotary sealed water jet cleaner includes a driving mechanism 1, a rotary sealing mechanism 2, a water inlet connector 22, a nozzle mechanism 3, an upper casing 39 and a lower casing 6, and the upper casing 39 is fixedly connected with the lower casing 6; the driving mechanism 1 includes an air motor 37, an air motor outer casing 38, a driving gear positioning pin 4 and a driving gear 5, and the rotary sealing mechanism 2 includes a water inlet joint 34, a sealing outer casing 33, Sealing inner passage 32, support shaft sleeve 29, sealing middle passage 24, gear positioning ring 26, and driven gear 25, said shower head mechanism 3 includes shower head main body 16 and two shower head assemblies arranged on the shower head main body 16, axial Fixing bolt 7, cleaning disc upper shell 8, radial fixing bolt 9, cleaning disc connecting sleeve 10, dynamic sealing ring 21, and cleaning disc lower shell 11, right n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com