Conduit bending molding equipment and conduit bending molding method

A bending forming and catheter technology, which is applied in the structural design and application field of catheter bending and forming equipment, can solve the problems of inability to realize the bending and forming of larger diameter catheters, heavy labor workload, and low productivity, so as to shorten the processing cycle and operation time Effect of shortening and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

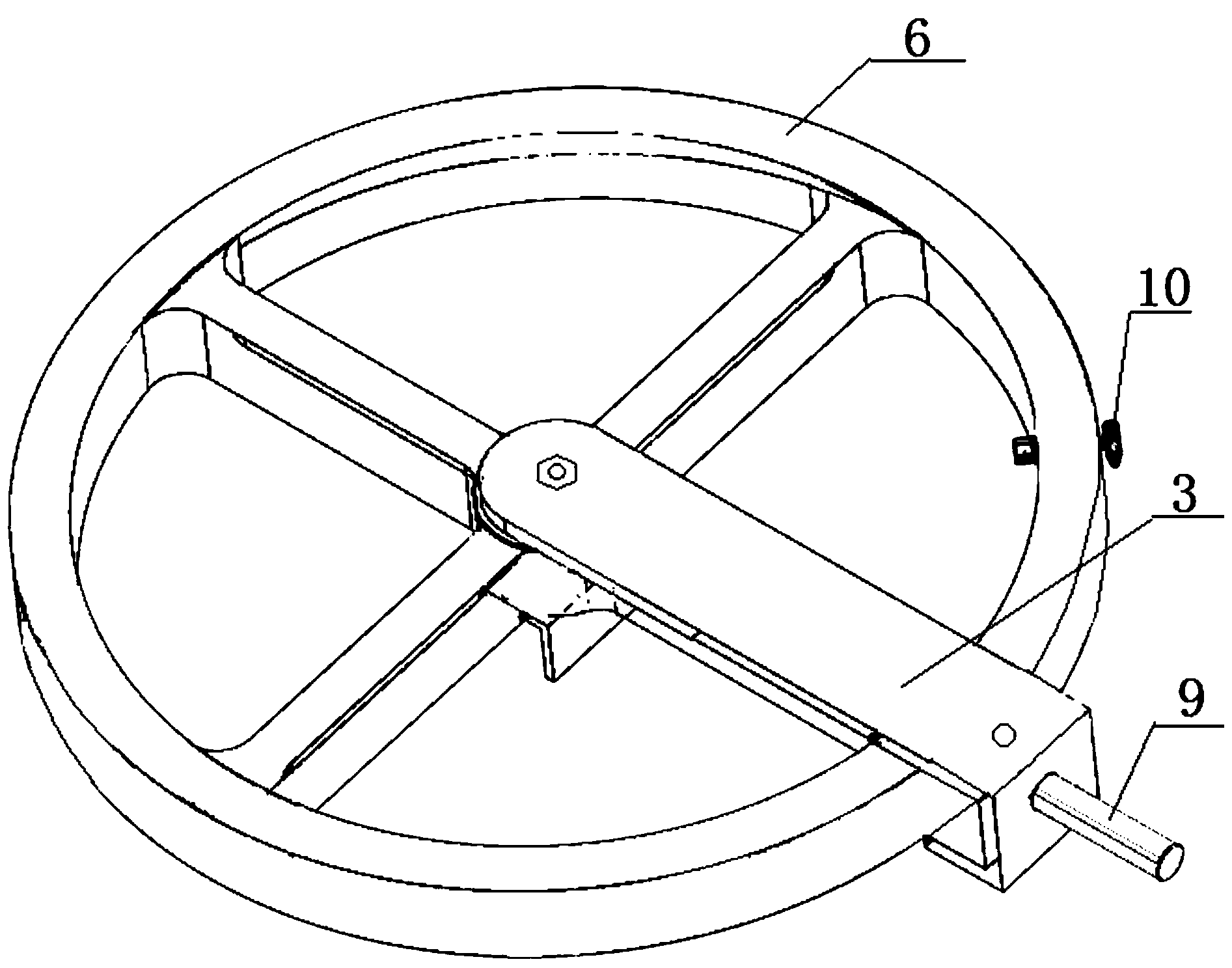

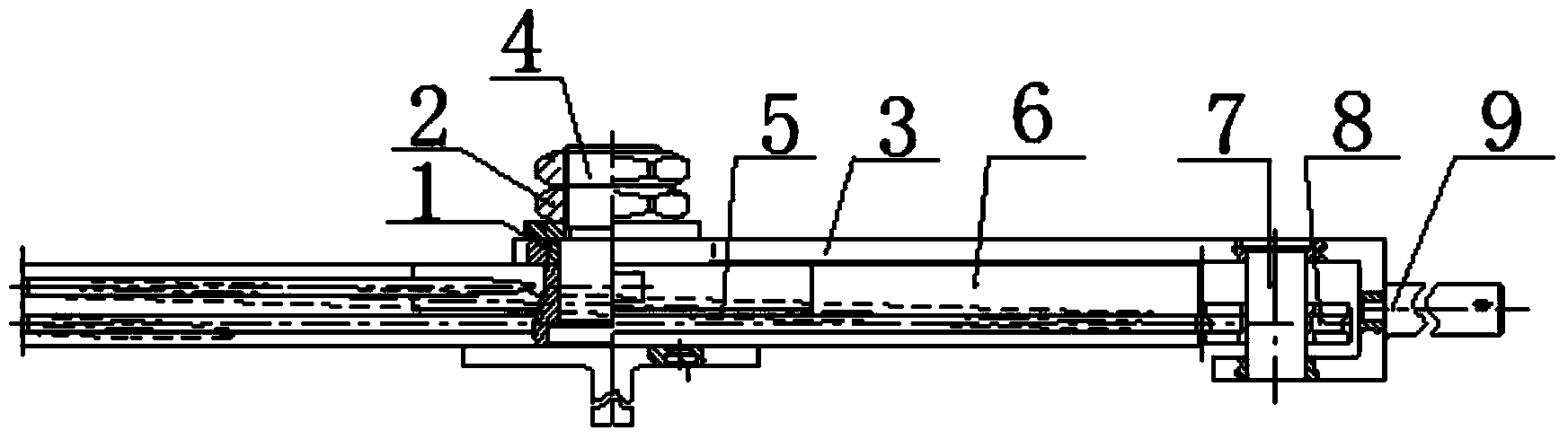

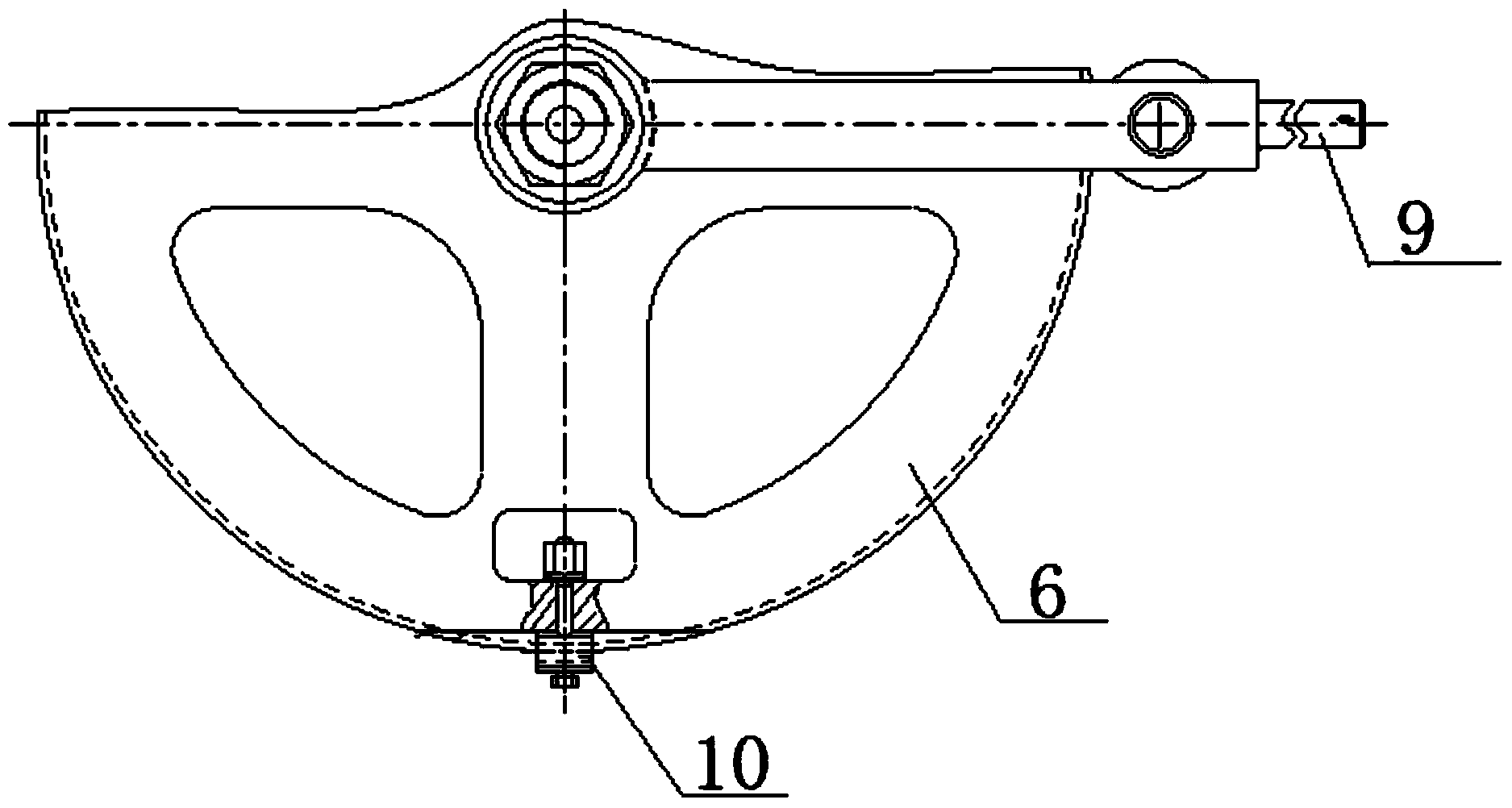

[0025] The catheter bending and forming equipment described in this embodiment is composed as follows: bushing 1, connecting piece 2, rotating arm 3, mandrel 4, fixing seat 5, rotating slide 6, pin 7, roller 8, handle 9, chuck 10; The mandrel 4 is fixed on the fixed seat 5 through the bushing 1 and the connecting piece 2, the rotating slideway 6 is a hollow ring structure, the rotating slideway 6 is sleeved on the mandrel 4 through the bracket, and the chuck 10 is passed through the connecting piece 2 is fixed on the rotating slideway 6, one end of the rotating arm 3 is sleeved on the mandrel 4, and the other end is slidably connected to the outside of the rotating slideway 6 through the pin 7 and the roller 8, and one end of the handle 9 is fixed on the rotating arm 3 .

[0026] The steps of using the catheter bending and forming equipment to bend and shape the catheter are as follows:

[0027] ①Initial pipe inspection: check the type of pipe material, check the outer surfac...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, the difference is:

[0041]The catheter bending and forming equipment described in this embodiment is composed as follows: bushing 1, connecting piece 2, rotating arm 3, mandrel 4, fixing seat 5, rotating slide 6, pin 7, roller 8, handle 9, chuck 10; The mandrel 4 is fixed on the fixed seat 5 through the bushing 1 and the connecting piece 2, the rotating slideway 6 is a hollow ring structure, the rotating slideway 6 is sleeved on the mandrel 4 through the bracket, and the chuck 10 is passed through the connecting piece 2 Fixed on the rotating slideway 6, one end of the rotating arm 3 is sleeved on the mandrel 4, and the other end is slidingly connected to the outside of the rotating slideway 6 through the pin 7 and the roller 8, and one end of the handle 9 is fixed on the rotating arm 3 .

[0042] The steps of using the catheter bending and forming equipment to bend and shape the catheter are as follows:

[0043] ...

Embodiment 3

[0052] The catheter bending and forming equipment described in this embodiment is composed as follows: bushing 1, connecting piece 2, rotating arm 3, mandrel 4, fixing seat 5, rotating slide 6, pin 7, roller 8, handle 9, chuck 10; The mandrel 4 is fixed on the fixed seat 5 through the bushing 1 and the connecting piece 2, the rotating slideway 6 is a hollow ring structure, the rotating slideway 6 is sleeved on the mandrel 4 through the bracket, and the chuck 10 is passed through the connecting piece 2 is fixed on the rotating slideway 6, one end of the rotating arm 3 is sleeved on the mandrel 4, and the other end is slidably connected to the outside of the rotating slideway 6 through the pin 7 and the roller 8, and one end of the handle 9 is fixed on the rotating arm 3 .

[0053] The steps of using the catheter bending and forming equipment to bend and shape the catheter are as follows:

[0054] ①Initial pipe inspection: check the type of pipe material, check the outer surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com