Clamping tool for fastener measurement

A fastener and clamping technology, applied in the field of mechanical fastener measurement, can solve problems such as inability to accurately pick points, inability to clamp fasteners, and decrease in fastener measurement efficiency, so as to reduce labor intensity and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

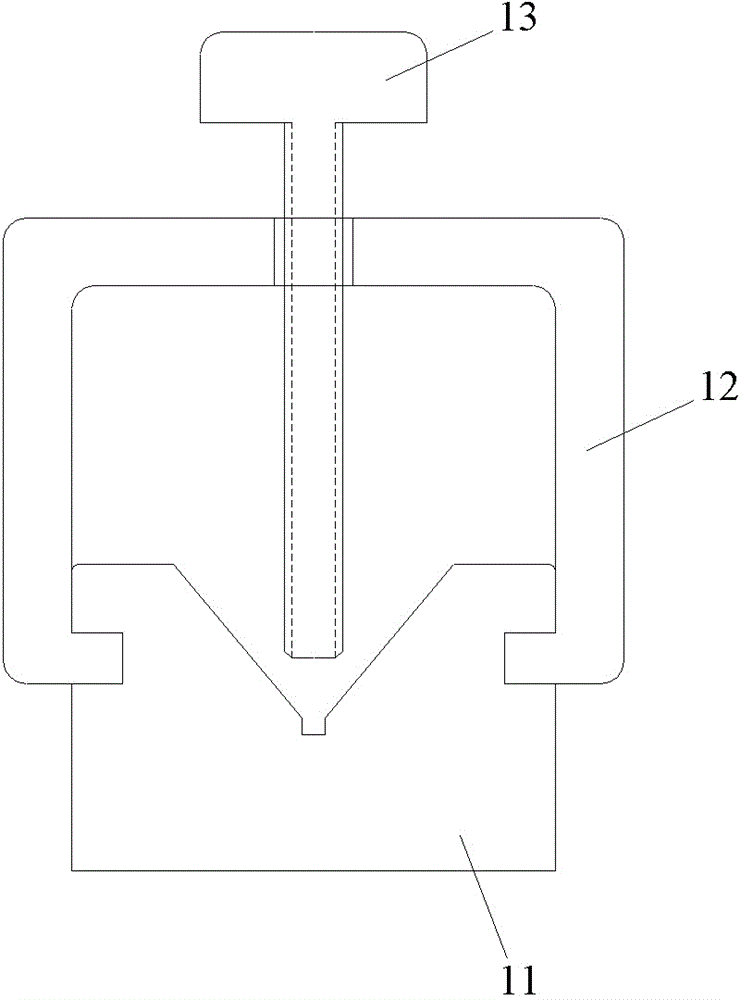

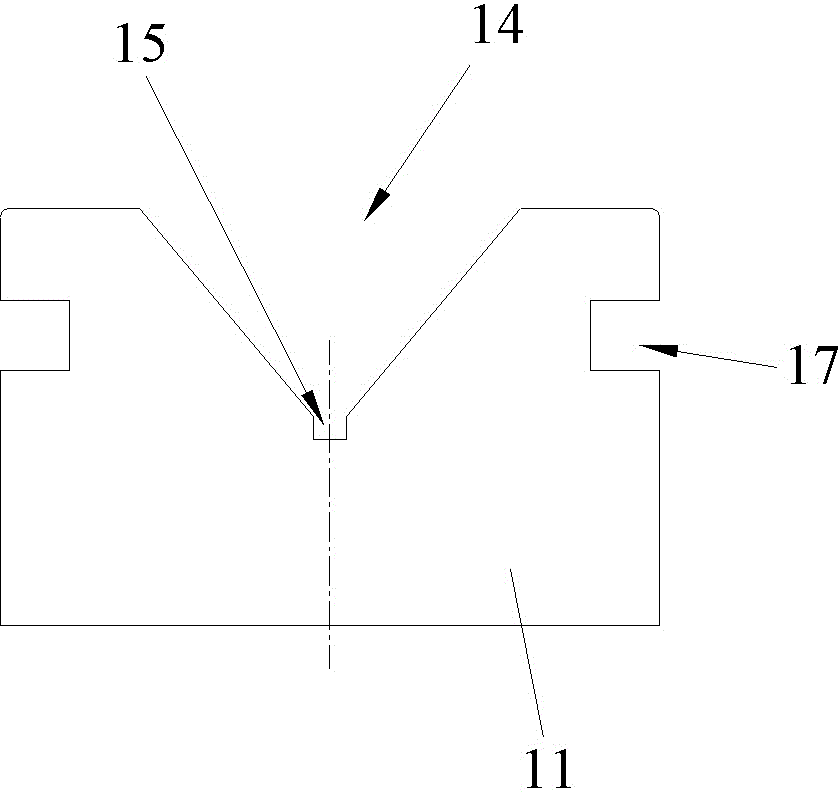

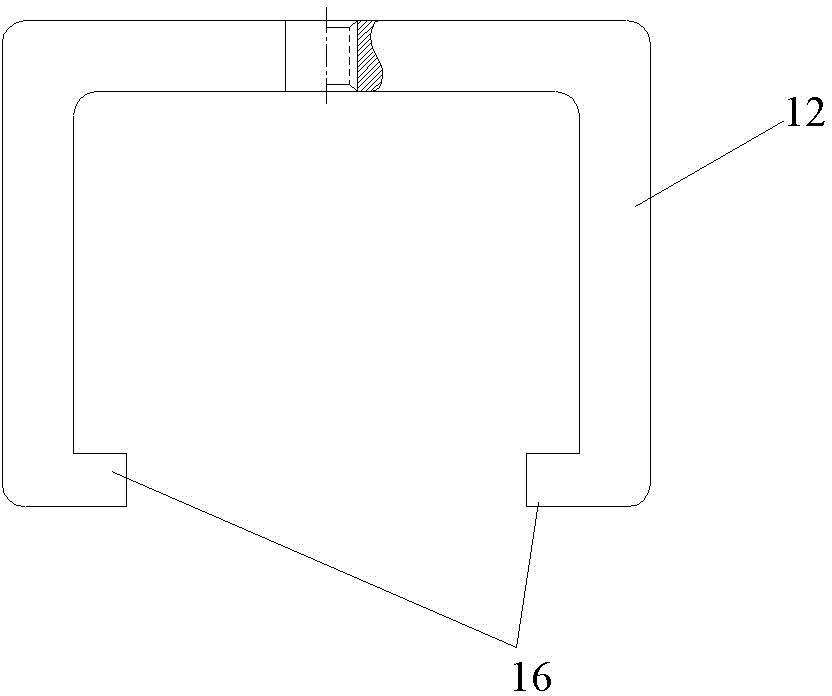

[0016] Examples of clamping tooling for fastener measurement, such as Figure 1-4 As shown, the clamping tool for fastener measurement includes a base 11 and a pressing part, and the pressing part includes a support frame 12 and a pressing screw 13 .

[0017] The base 11 is in the shape of a plate, and a positioning groove 14 is provided at one edge of the base 11. The positioning groove 14 runs through the thickness direction of the plate formed by the base 11. In this embodiment, the positioning groove 14 is a V-shaped groove. The locating groove is more helpful for centering the fastener under test. In addition, in this embodiment, the bottom of the positioning groove 14 is also provided with an impurity accommodating groove 15. During the use process, the impurities dropped from the fastener to be tested can accumulate in it, so as to prevent it from being cushioned by the fastener. The accuracy of the measurement results is affected by the measurement under the fastener....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com