Rotary type flexible joint

A flexible joint and rotary technology, applied in the field of robots, to achieve the effects of reducing impact, improving service life and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof. However, the protection scope of the claims of the present application is not limited to the description scope of the embodiments.

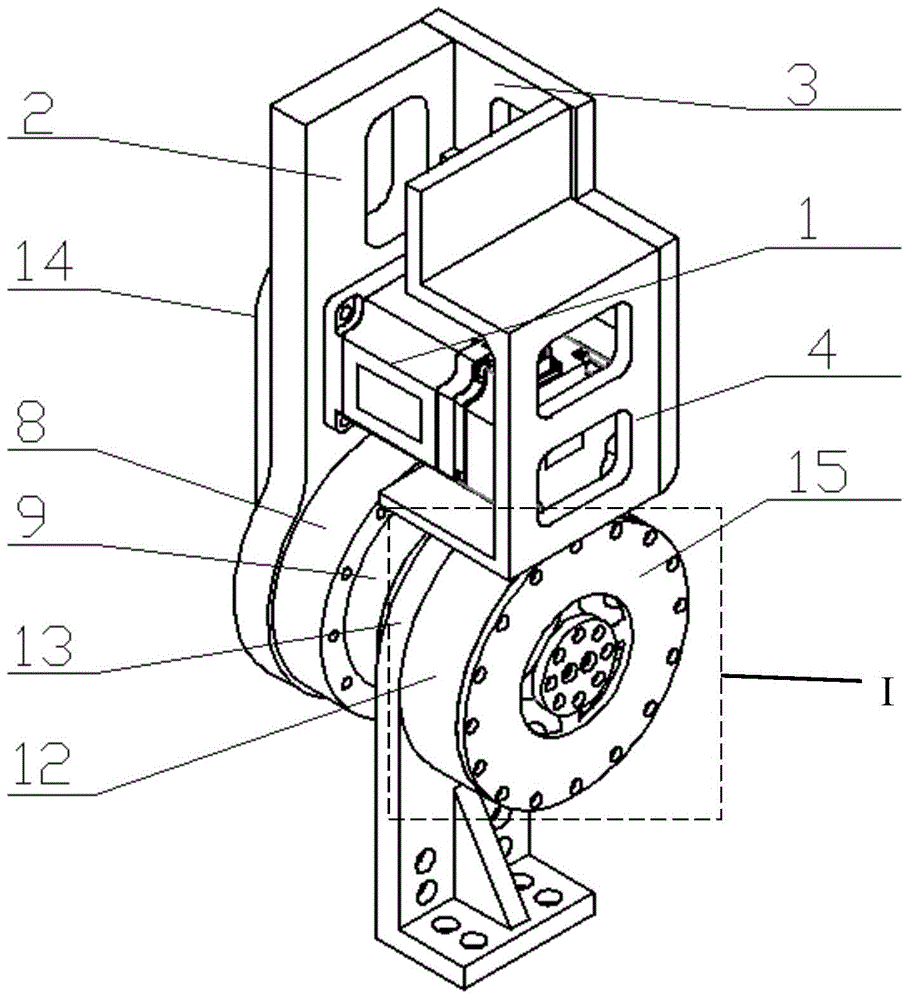

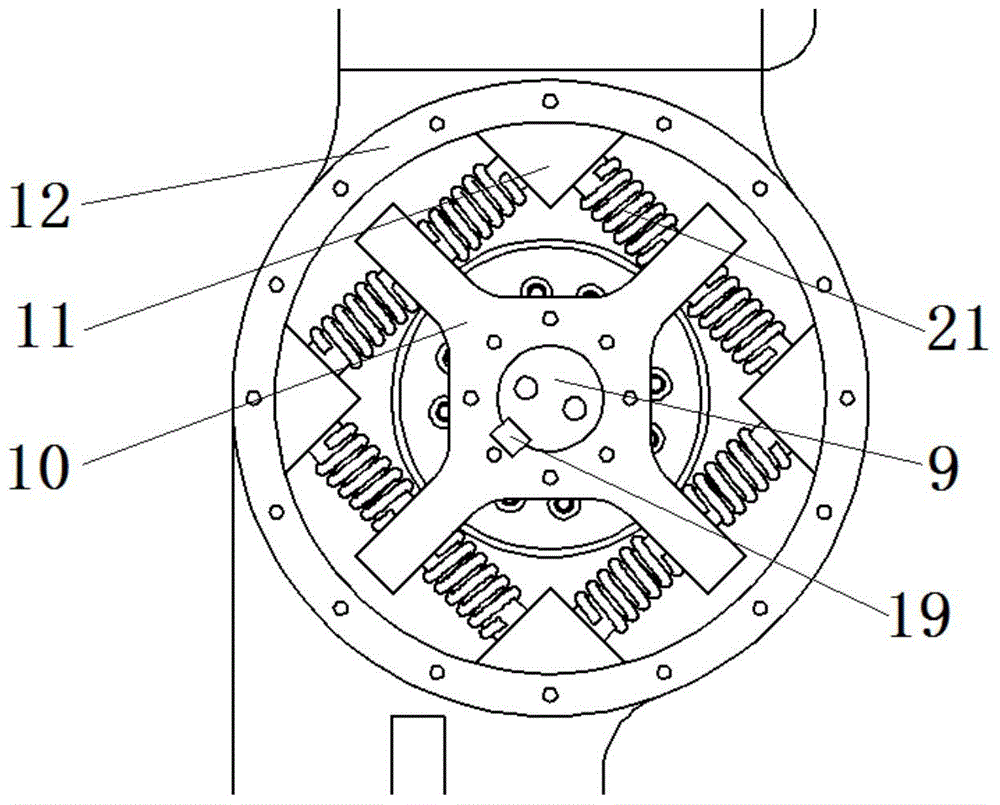

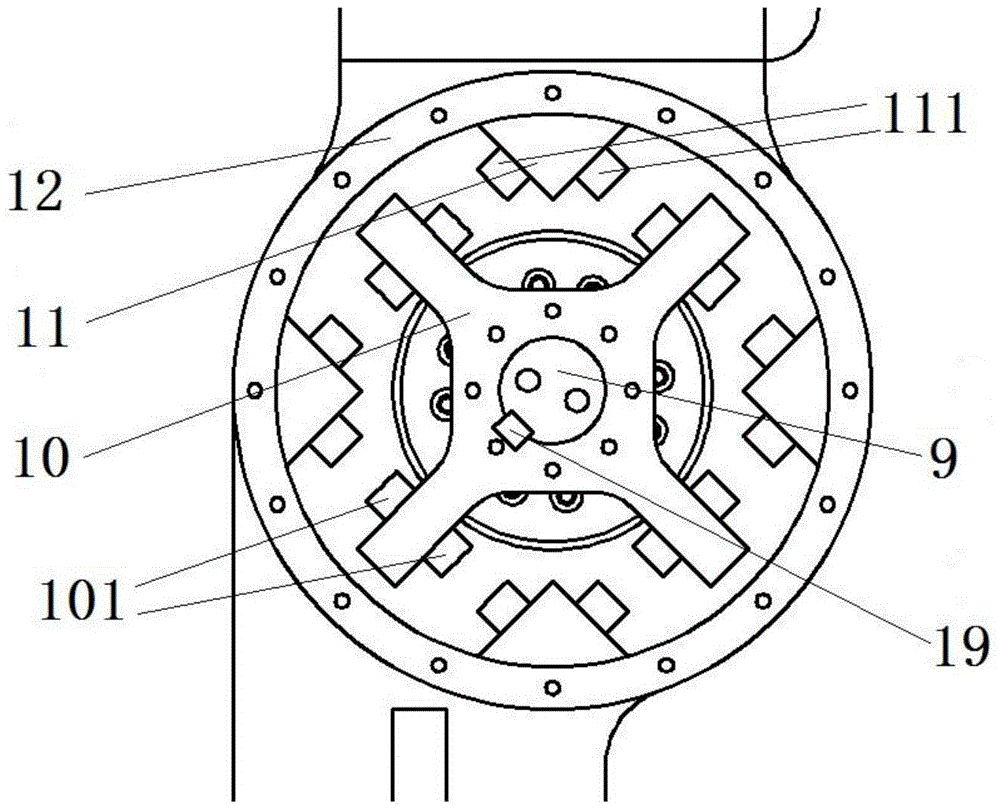

[0016] A rotary flexible joint designed by the present invention (flexible joint for short, see Figure 1-4 ), characterized in that the flexible joint includes a motor 1, a motor frame 2, a mounting plate 3, a first connecting plate 4, a first synchronous pulley 5, a first synchronous pulley cover plate 6, a synchronous belt 7, a reducer 8, Reducer flange 9, spring mounting frame 10, spring output frame 11, output plate 12, second connecting plate 13, synchronous belt end cover 14, third connecting plate 15, cross roller bearing 16, bearing outer ring baffle 17 , Bearing inner ring baffle 18, first flat key 19, reducer flange end cover 20, spring 21, second flat key 22, third flat key 23, second synchronous pulley 24 and second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com