Soft and hard co-extrusion air duct guard plate extrusion device for sealing

An air duct guard, soft and hard co-extrusion technology, applied in the field of soft and hard co-extruded air duct guard extrusion device for sealing, can solve the problems of high tear strength at the joint of soft and hard, affecting the service life of the product, etc., to achieve Enhanced adhesive performance, improved productivity, and quality assurance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

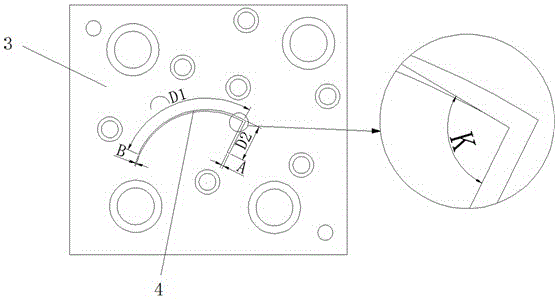

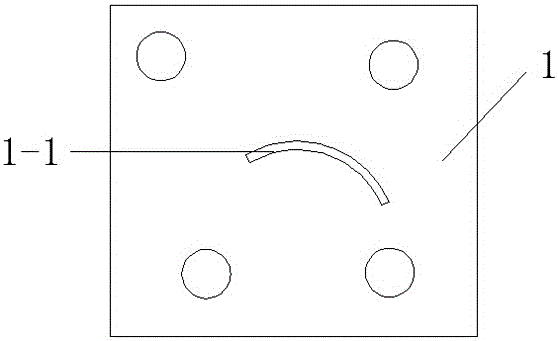

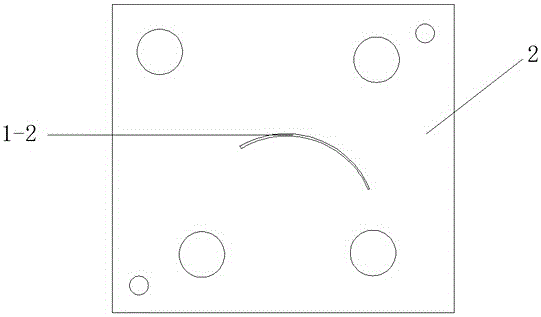

[0015] Embodiment of the present invention: the structure of the air duct guard plate extrusion device for soft and hard co-extrusion sealing is as follows figure 1 As shown, the die head 1 is included, the first section of the functional part flow channel 1-1 is provided on the die head 1, the end of the die head 1 is connected with a transition plate 2, and the second section of functional parts is provided on the transition plate 2 The flow channel 1-2 is provided with a mouth template 3 at the end of the transition plate 2, and the structural part flow channel 5 and the third functional part flow channel 1-3 are arranged on the mouth template 3, and the functional part flow channels of each section are connected in sequence , the lateral structural member flow channel 3-1 communicates with the forward structural member flow channel 3-2, and the third functional part flow channel 1-3 and the structural member flow channel 5 are located 10-12mm in front of the outlet end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com