Cross beam vibration absorption structure of vehicle instrument

A technology for automotive instruments and beams, applied in the direction of instrument panel, upper structure, upper structure sub-assembly, etc., can solve the problems that affect the quality of the car, and there is no good solution, so as to improve the quality of the car, easy to implement, and cost-effective low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

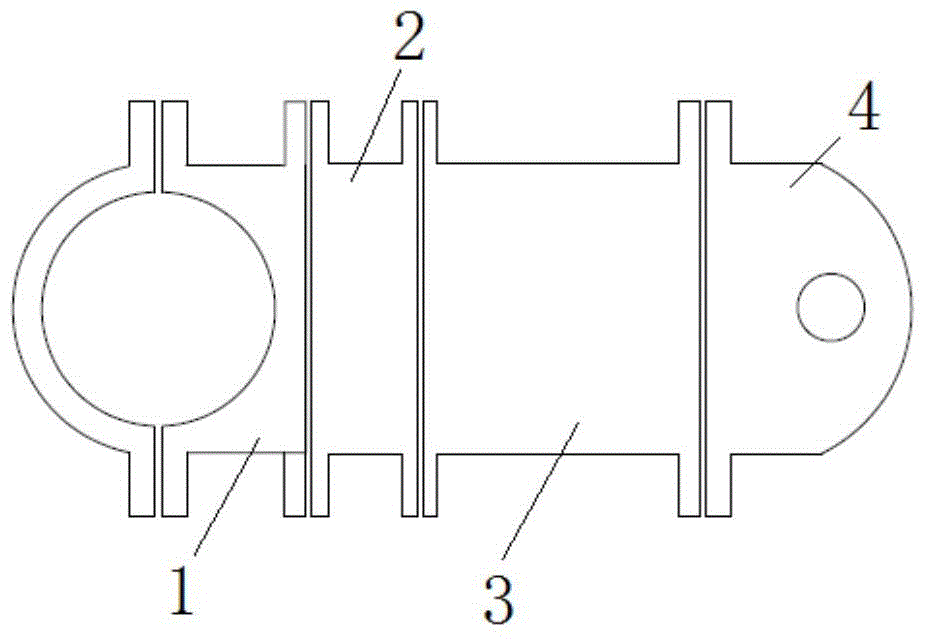

[0017] Such as figure 1 As shown, the automobile instrument beam vibration-absorbing structure includes an instrument beam connecting seat 1, a rubber block 2, a weight block 3, and a vehicle body rubber connecting block 4, wherein the instrument beam connecting seat 1 is a two-semicircle structure that is docked, and the two semi-circle structure ferrules On the crossbeam of the automobile instrument, the two semicircular structures are protruded with ear plates, and after the two semicircular structures are butted, the bolts pass through the bolt holes on the ear plates to fix them together.

[0018] An annular groove is arranged on the inner wall of the instrument beam connecting seat 1, and a rubber ring is arranged in the annular groove, and the rubber ring protrudes from the annular groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com