Automobile radiator crossbeam made of fiber reinforced composite material and manufacturing method thereof

A reinforced composite material, fiber-reinforced technology, applied in vehicle components, substructure, transportation and packaging, etc., can solve the problems of increasing the weight of the body, increasing the weight of the beam of the water tank, and not conforming to the lightweight of the automobile structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

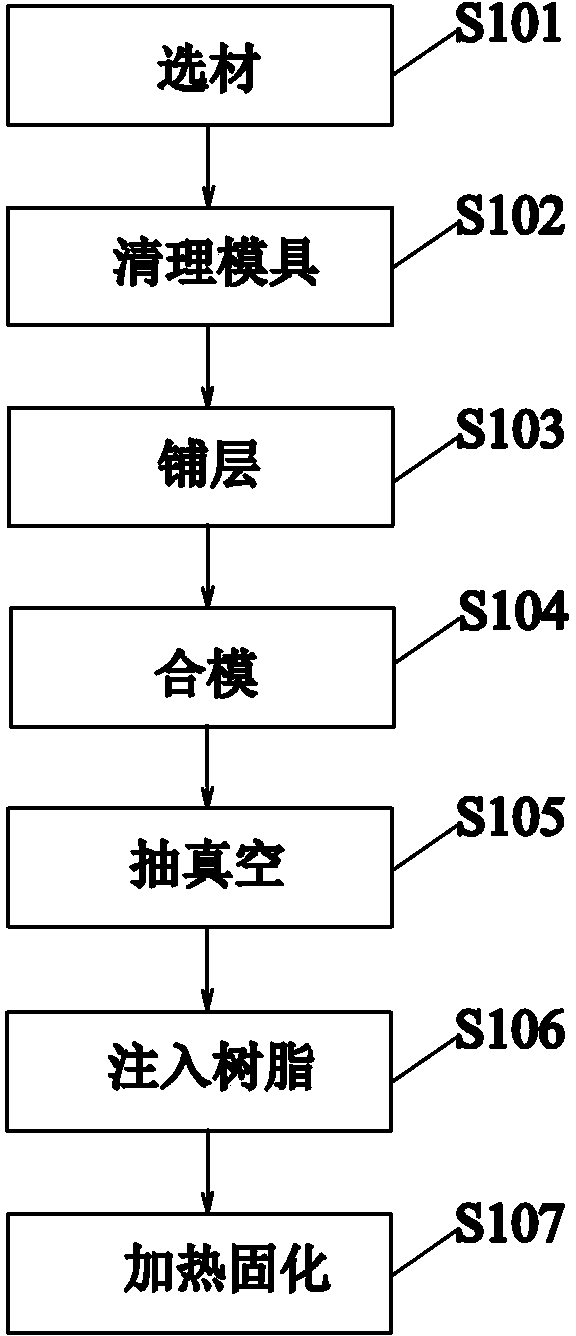

[0021] Such as figure 1 As shown, the manufacturing method of the fiber-reinforced composite automobile radiator beam provided by the embodiment of the present invention, the manufacturing method at least includes:

[0022] Step S101, material selection.

[0023] Fiber-reinforced composite materials can be selected from glass fiber-reinforced composite materials, carbon fiber-reinforced composite materials, aramid fiber-reinforced composite materials, basalt fiber-reinforced composite materials or mixed fiber-reinforced composite materials; foam layer materials are selected from PVC foam materials, PET foam materials, PU Foam material, SAN foam or PMI foam material; the resin is epoxy resin, unsaturated polyester resin, vinyl resin, phenolic resin or bismaleimide resin.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com