Novel automatic reagent bottle capping and uncapping mechanism

An automatic switch and reagent bottle technology, which is applied in snap-on bottle caps, bottle/container caps, bottle filling, etc., can solve the problems of time-consuming, complex structure, energy consumption, etc., reduce complex mechanical mechanisms, and improve work efficiency , slowing down effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

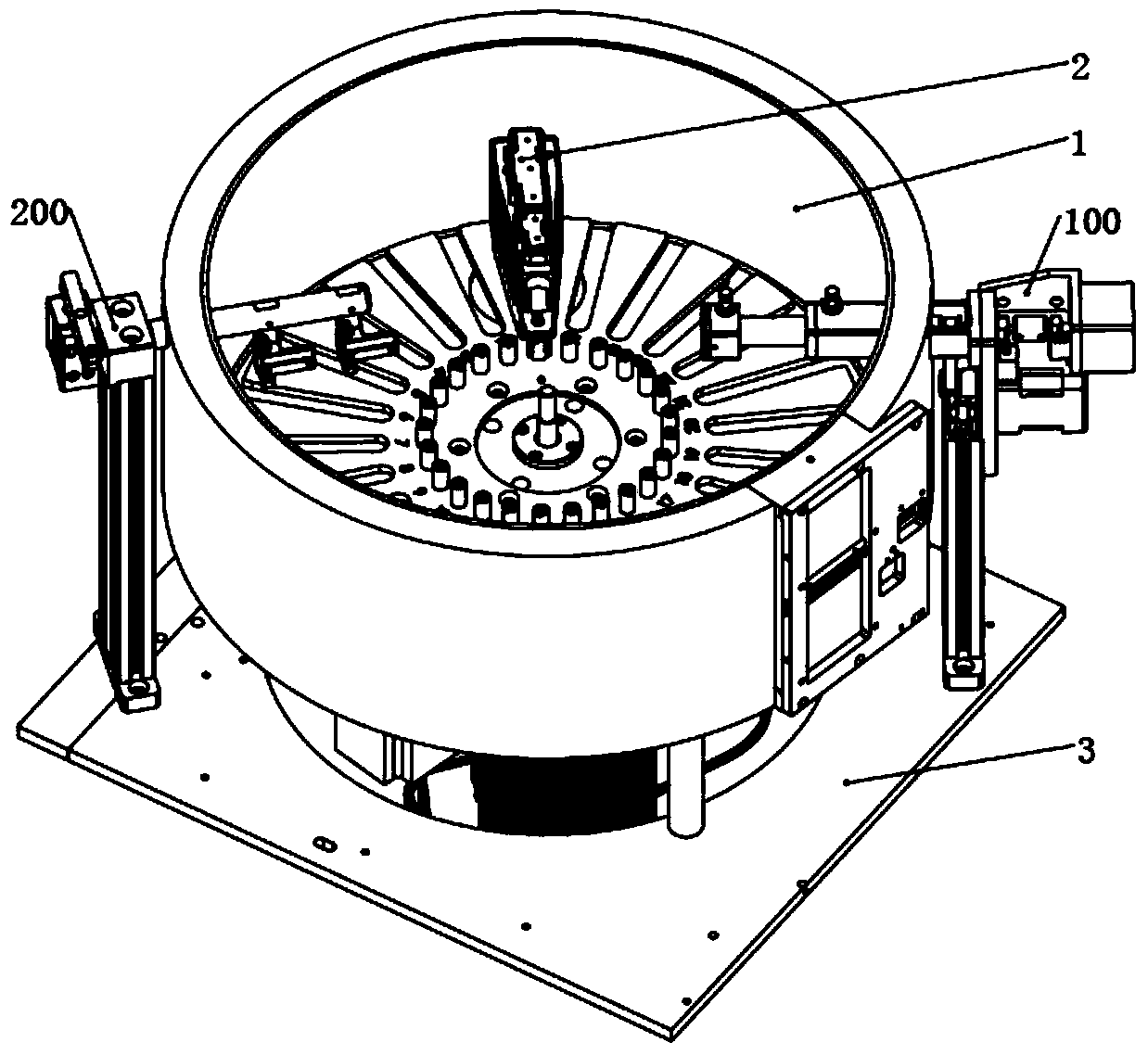

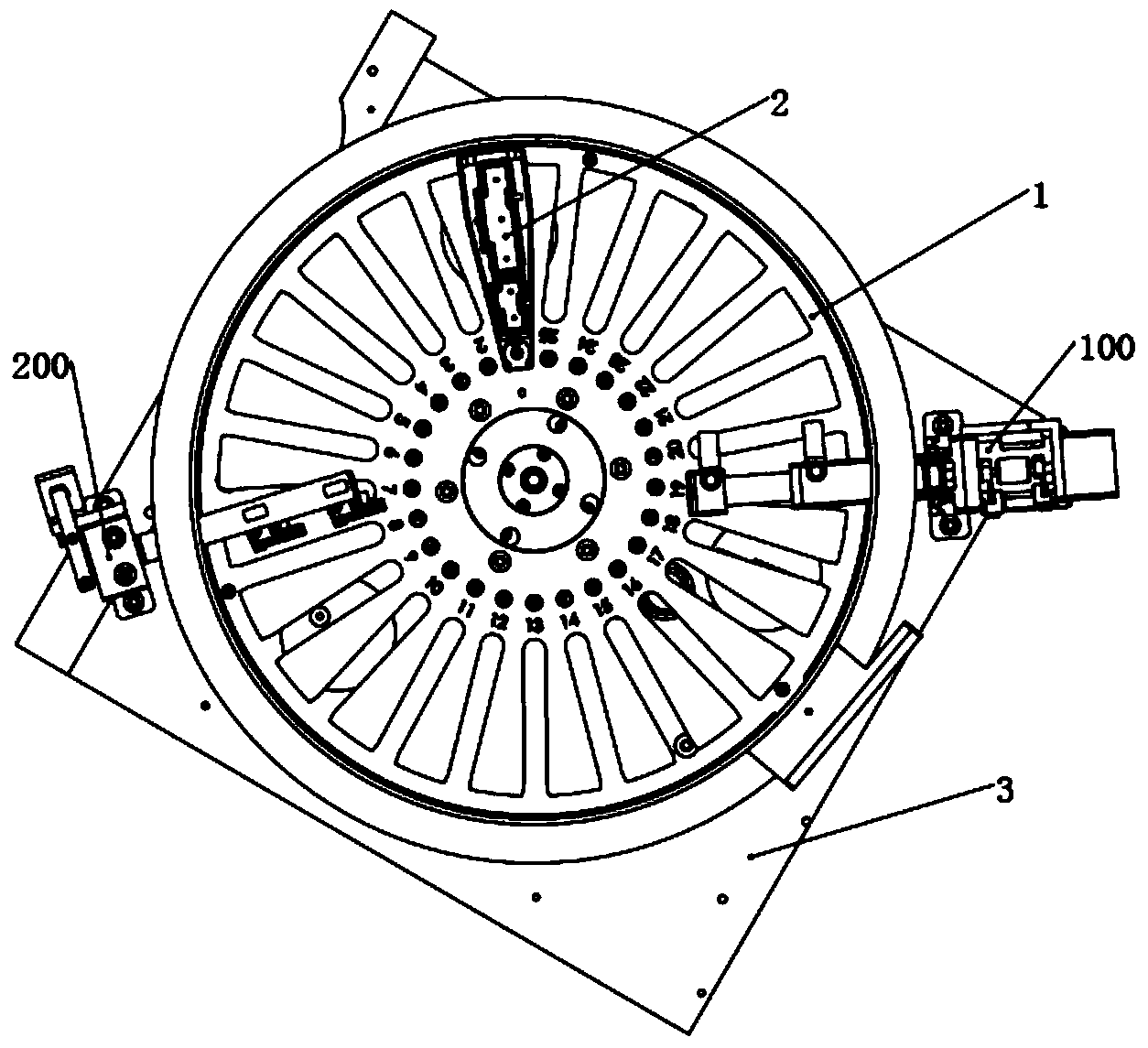

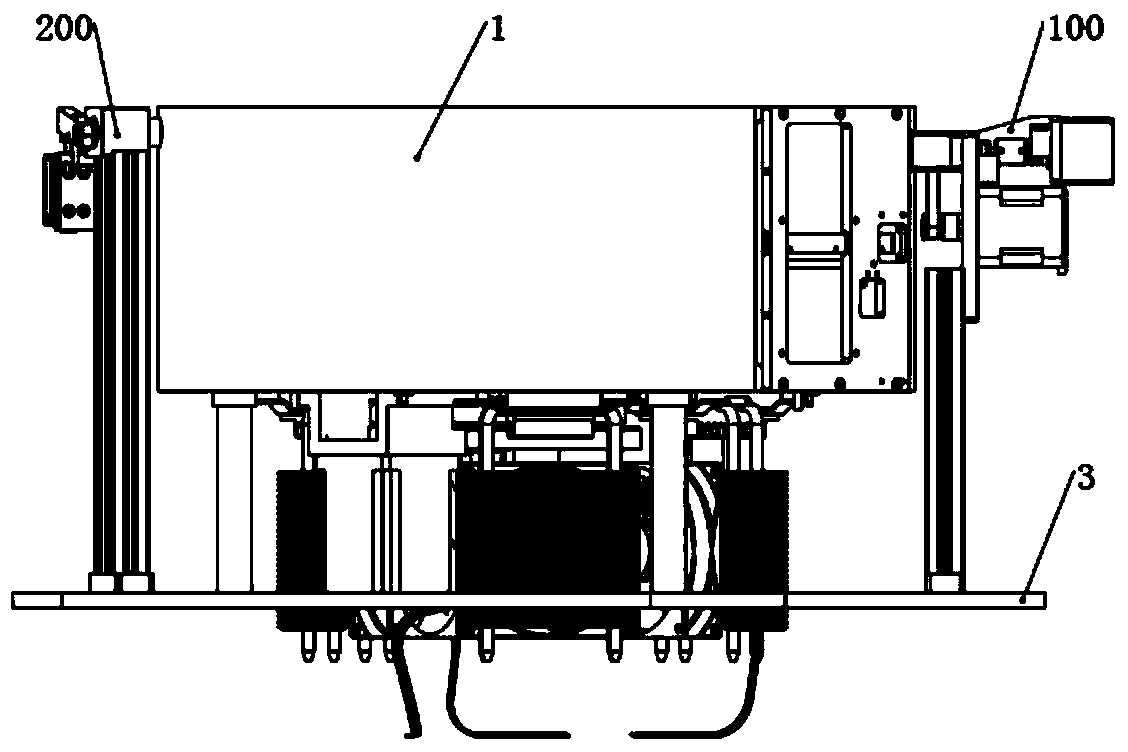

[0071] like Figure 1-Figure 3 As shown, it is a schematic diagram of the integrated structure of the automatic opening and closing mechanism of the reagent bottle and the reagent disc according to the present invention.

[0072] A new type of automatic opening and closing mechanism for reagent bottles, including an opening mechanism 100 and a closing mechanism 200, which automatically opens and closes the reagent installed on the reagent bottle 2 through the opening mechanism 100 and the closing mechanism 200 integrated on the reagent tray 1 bottle cap;

[0073] like Figure 4 As shown, each card position in the reagent tray includes two reagent bottles, and the first reagent bottle cap includes a first hinged sheet type cover 5, a first buckle 4 and a first uncap spring 6; The bottle cap of the reagent bottle includes a second hinged sheet cap 8, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com