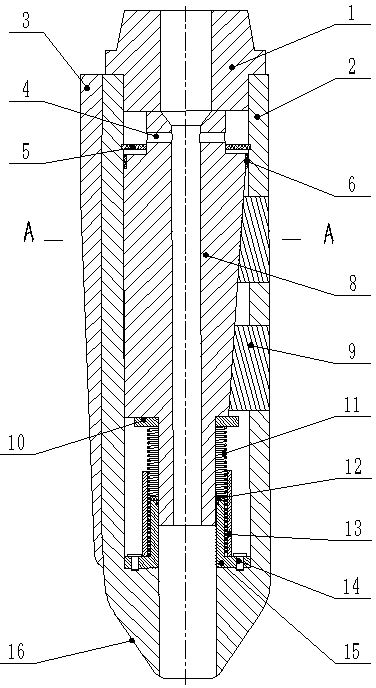

Novel underground controllable casing pipe shaping device

A technology for shaping devices and casings, applied in wellbore/well components, earth-moving drilling and other directions, can solve problems such as economic losses, casualties, environmental pollution, etc., and achieve the effects of improving economic benefits, long service life, and flexible movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

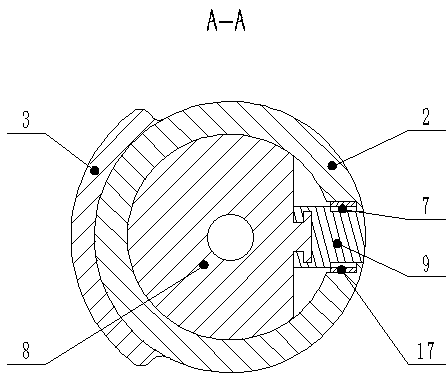

[0012] Depend on figure 1 As shown, a downhole controllable casing shaping device is composed of a casing 2, a body 8, a hard support block 9, a return spring 11, a positioning sleeve 13, and a shaft sleeve 15. It is characterized in that: the connector 1. The upper end is connected to the oil pipe through threads, and the lower end is connected to the casing 2 through threads. There is a shaped prism 3 on one side of the outer surface of the casing 2. The lower end of the casing 2 is a conical guide cone 16; in the inner cavity of the casing, the filter screen 5 is located inside On the upper part of the cavity, a cylindrical body hole 4 is opened on the upper end of the body 8, the body 8 is in clearance fit with the housing 2, and the upper end of the body 8 is equipped with an O-shaped rubber sealing ring 6 radially, and one side of the body 8 has an I-shaped inclined guide rail, hard The support block 9 is installed in the housing hole 7, the housing hole 7 is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com