a servo cylinder

A technology of servo cylinder and cylinder barrel, which is applied in the field of servo cylinder and can solve problems such as complicated installation and debugging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

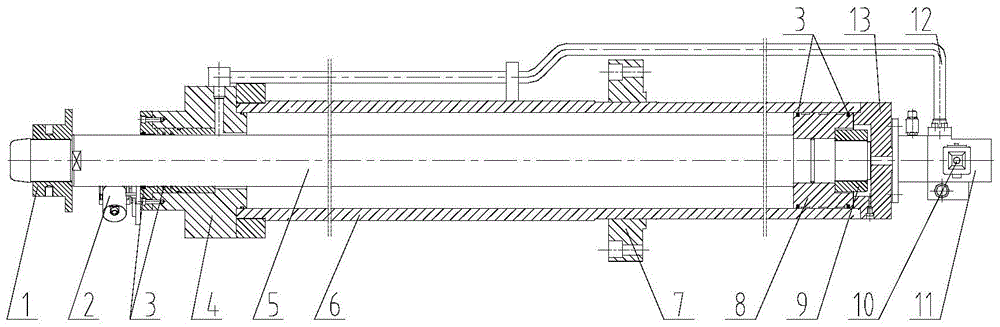

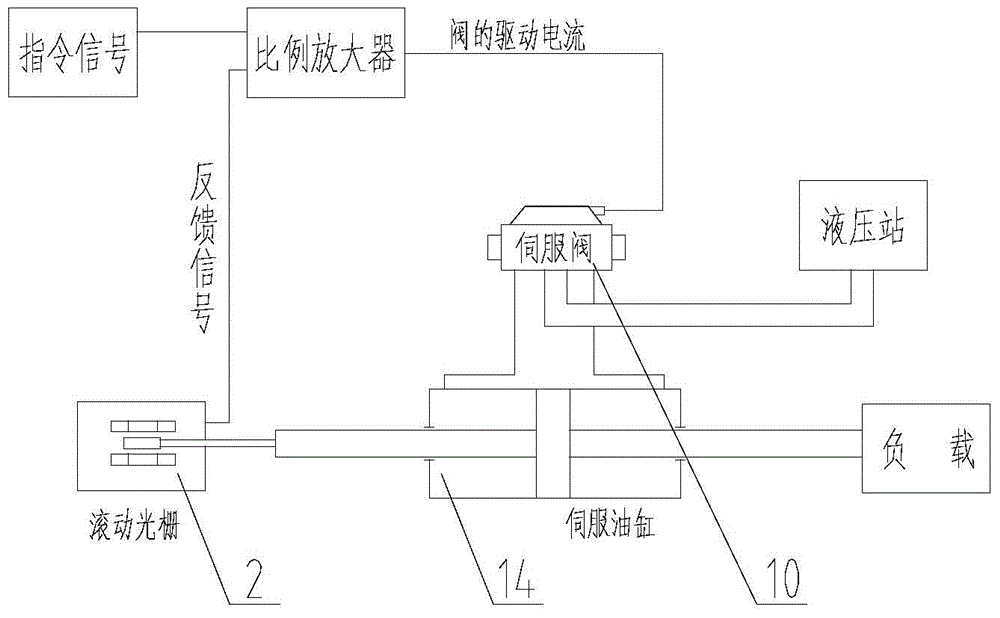

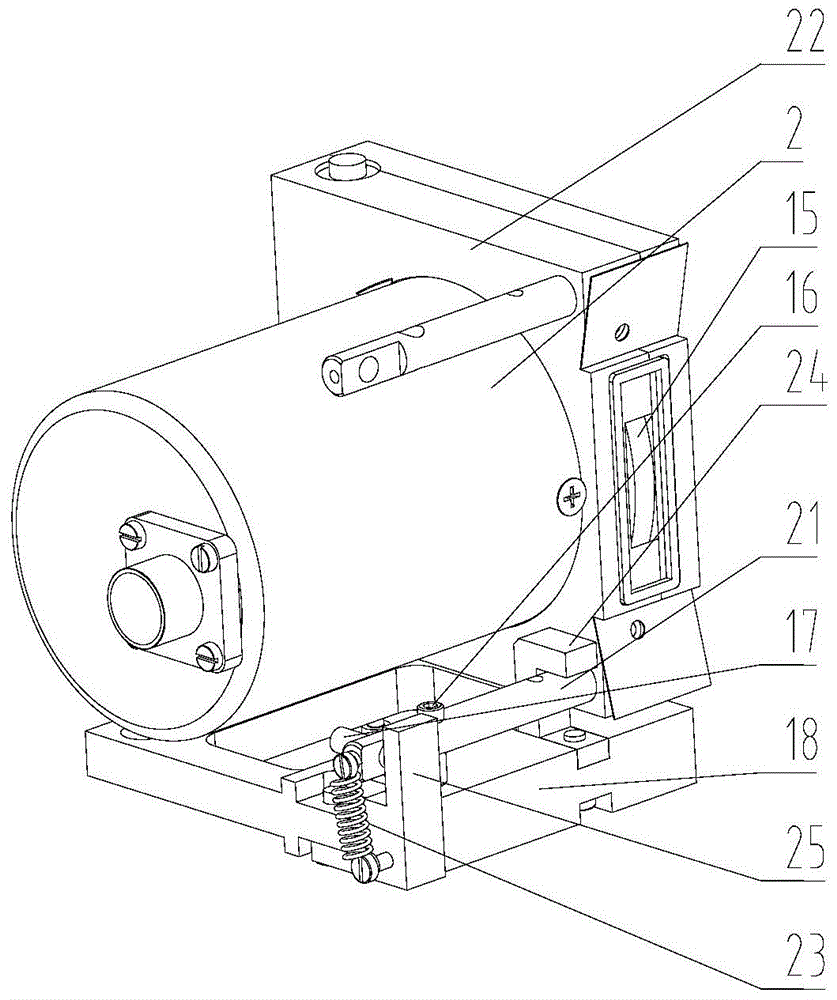

[0018] See attached Figure 1~6 As shown, this kind of servo cylinder, the servo cylinder 14 is a double-acting piston type, and the structural parts of the servo cylinder 14 include a round nut 1, a seal 3, a front end cover 4, a piston rod 5, a cylinder barrel 6, a flange 7, a piston 8. Buffer mechanism 9, integrated block 11, rear end cover 13 and upper chamber oil pipe 12, cylinder 6 is made of high-quality thick-walled seamless steel pipe, and the interior is rolled to ensure a good finish. The front end of cylinder 6 is welded by bolts The method is fixed with the front end cover 4, the rear part of the cylinder 6 is fixedly connected with the rear end cover 13 by welding, the rear part of the inner cavity of the cylinder 6 is provided with a buffer mechanism 9 for the smooth stop of the piston 8 when it returns, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com